I don't know if this has been covered, I didn't find a reference to it in the stickies. A good freind brought me hid 3D Maglite and could not remove the tailcap, he had replaced the batteries about 6 months ago and put a little lube on the threads when reassembling it. I finally got it apart and found that he had used a graphite based lube, which from being an M-16/AR15 armorer I know from past experience is a bad combo on aluminum threads. I was however surprised at how fast the reaction between the aluminum and graphite happened. I have never seen this bad a reaction in this short a time period in 40 years of gunsmithing. Their are some in the shooting world that don't believe that graphite is bad on any aluminum parts, I have personally seen it several times, it may have been worse this time on the Maglite due to too much moisture in the storage environment or maybe the grade of aluminum or some other cause, I have no clue but as I tell all my friends when they are building or maintaining their AR-15's. So now I can tell them also no graphite on their flashlites.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BAD Lube - graphite

- Thread starter renegade

- Start date

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

Kestrel

Flashaholic

Hello Renegade, thanks for this info.

From my background I know that Aluminum is a very good carbide-former, making it a good choice for cermet composites in specific situations.

Myself and others would be interested to see any pics you might be able to post if that's possible?

I will merge this post in with the rather extensive /Comprehensive Grease and Lube Thread/ shortly.

Best regards,

From my background I know that Aluminum is a very good carbide-former, making it a good choice for cermet composites in specific situations.

Myself and others would be interested to see any pics you might be able to post if that's possible?

I will merge this post in with the rather extensive /Comprehensive Grease and Lube Thread/ shortly.

Best regards,

Last edited:

more_vampires

Flashlight Enthusiast

- Joined

- Nov 20, 2014

- Messages

- 3,475

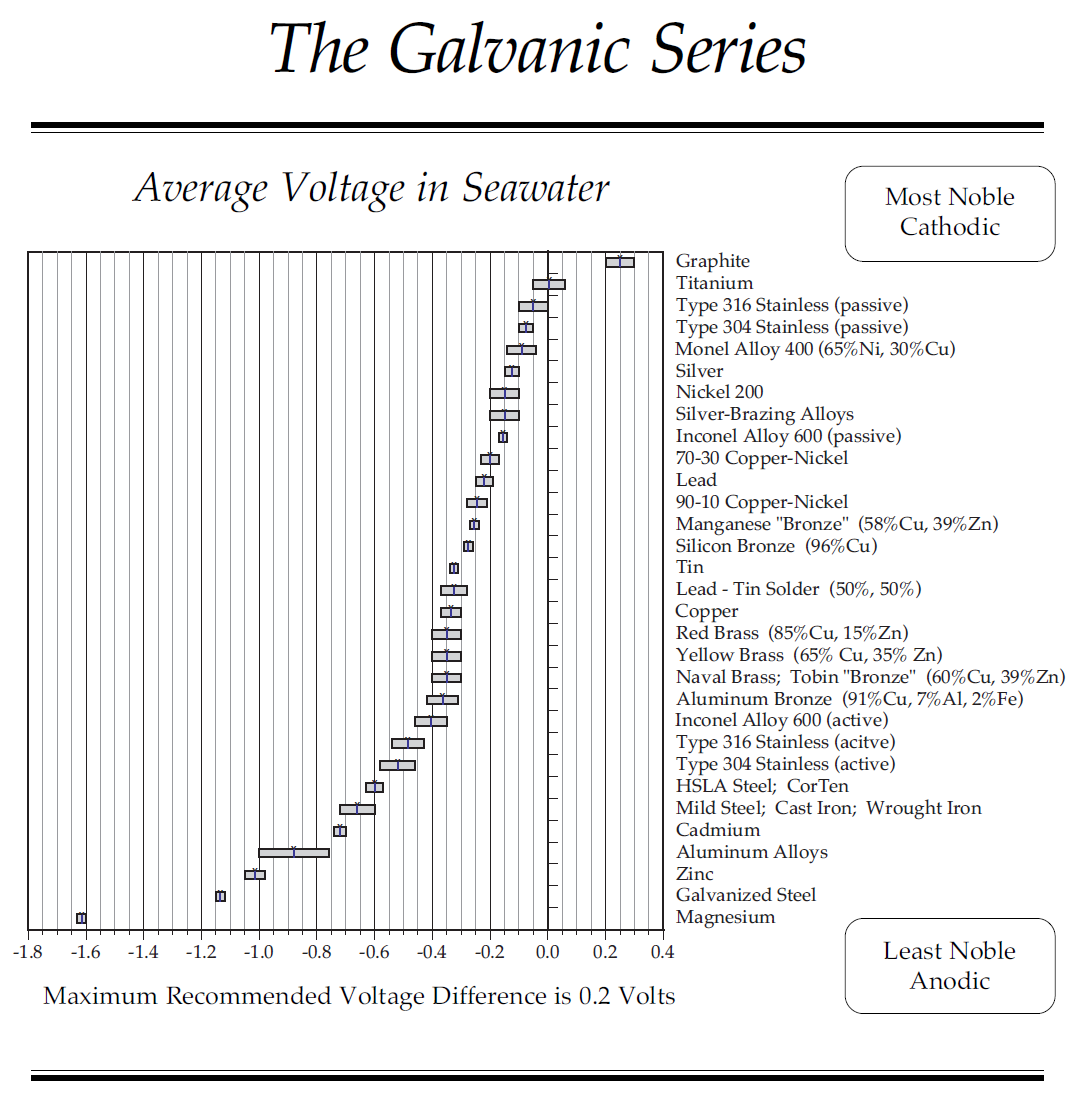

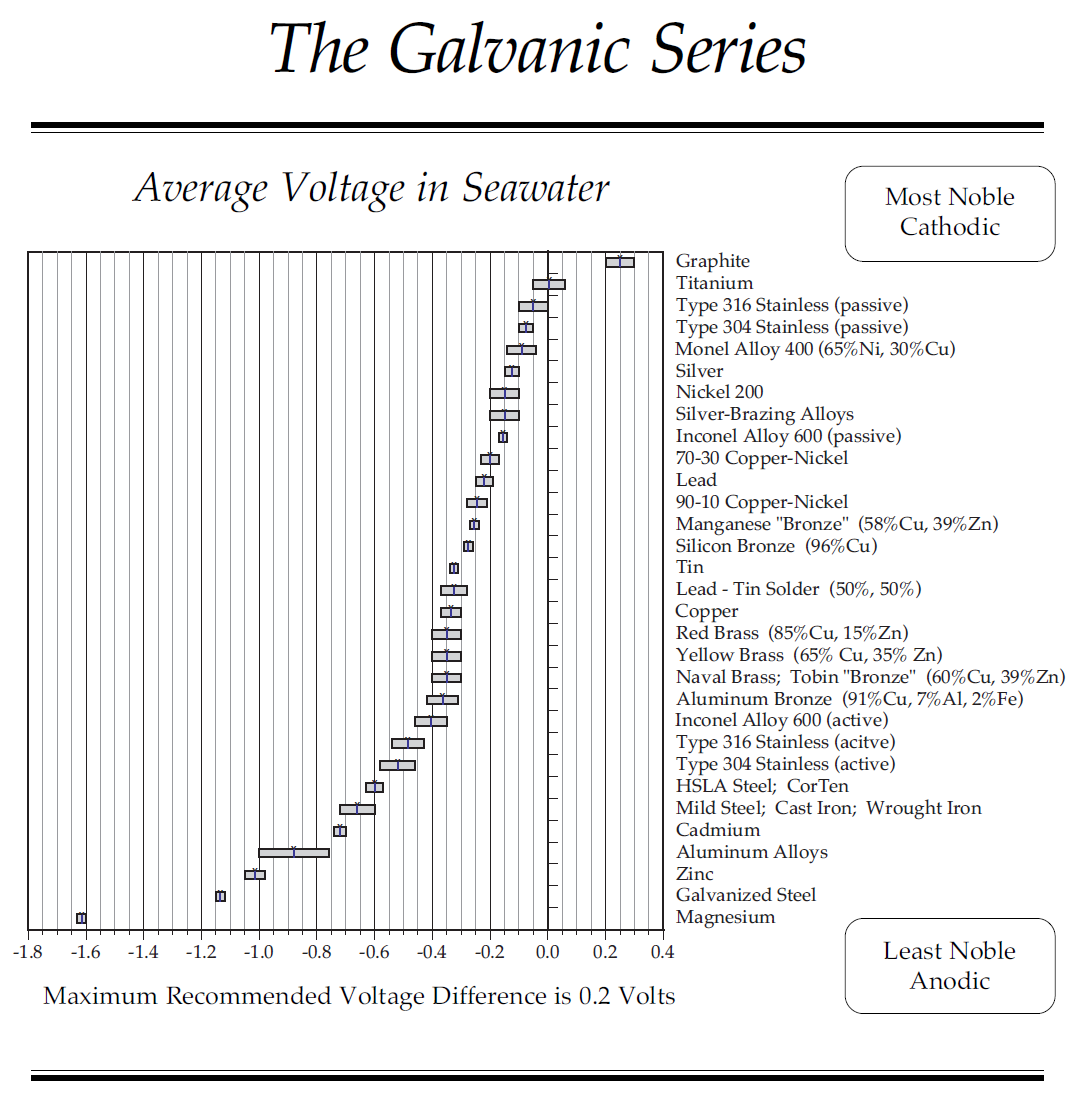

Corrosion by dissimilar materials. The energy flowing is a catalyst.I was however surprised at how fast the reaction between the aluminum and graphite happened. I have never seen this bad a reaction in this short a time period in 40 years of gunsmithing.

https://www.absoluterv.com/help-and...rmation/galvanic-corrosion-dissimilar-metals/

Aluminum + Carbon is a top offender.According to the Multimedia Corrosion Guide, the definition of Galvanic Corrosion is "the effect resulting from contact between two different metals or alloys in a conducting corrosive environment".

NoNotAgain

Flashlight Enthusiast

Yep.

We built some of the largest graphite composite structures that due to heat dissipation required the use of aluminum core. The core was PAA core and was coated with bonding corrosion resistant primer.

The graphite composite required a barrier layer of fiberglass or in short order you'd get galvanic corrosion. A couple hundred hours in a 95% humidity chamber heated to 140F on unprotected graphite would turn the core to white powder. Great low voltage battery.

On the AR platform though, the aluminum is anodized and the only area other than the take down pins would be the fire control parts.

I use moly lube on all of the pins and for barrel installation. Use sparingly as you will end up wearing it on your face or clothing.

If you look at this noble chart, the closer the elements are together the less frequency of corrosion.

We built some of the largest graphite composite structures that due to heat dissipation required the use of aluminum core. The core was PAA core and was coated with bonding corrosion resistant primer.

The graphite composite required a barrier layer of fiberglass or in short order you'd get galvanic corrosion. A couple hundred hours in a 95% humidity chamber heated to 140F on unprotected graphite would turn the core to white powder. Great low voltage battery.

On the AR platform though, the aluminum is anodized and the only area other than the take down pins would be the fire control parts.

I use moly lube on all of the pins and for barrel installation. Use sparingly as you will end up wearing it on your face or clothing.

If you look at this noble chart, the closer the elements are together the less frequency of corrosion.

Similar threads

- Replies

- 10

- Views

- 704