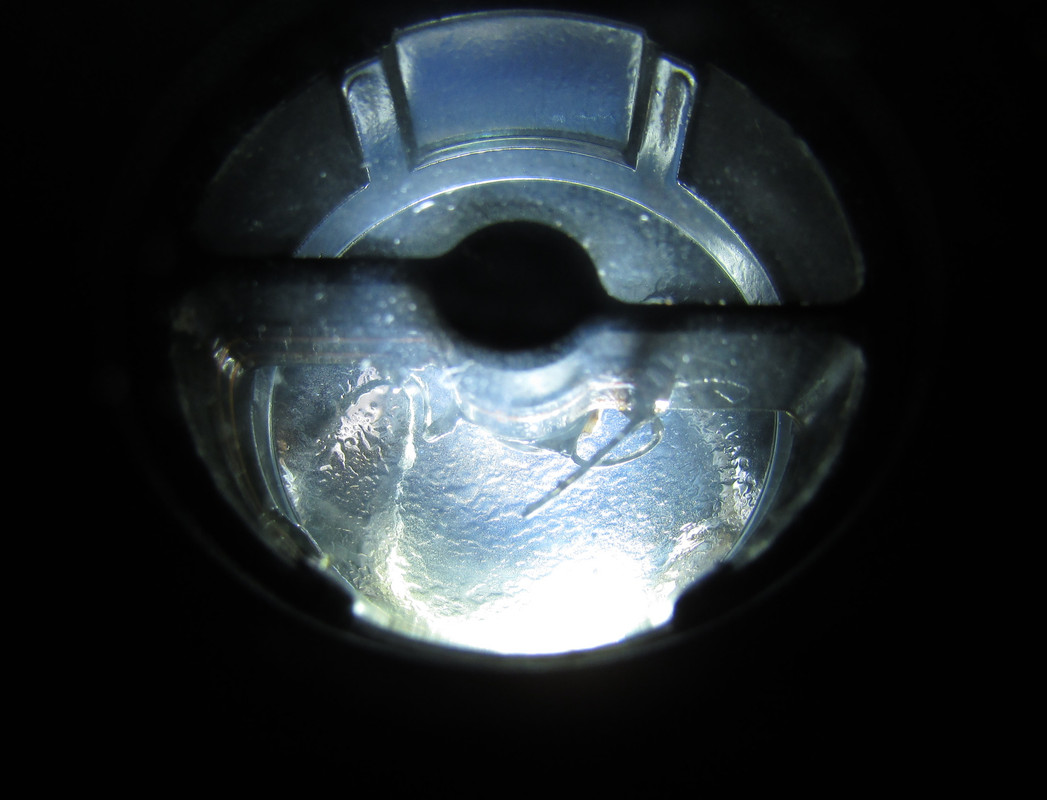

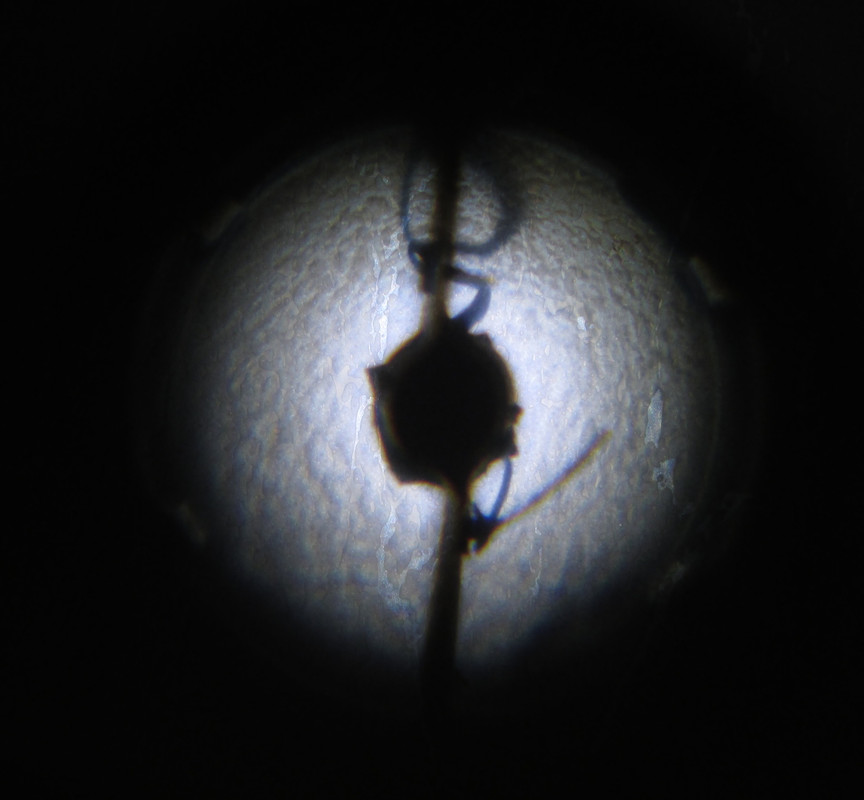

Hello, my friend and I decided to change Seoul to something more modern. The diode rises easily, soldering wires to the loop is also not very difficult, but there was a problem with reliability. The diode board is essentially held only by the tension of the wires. If you hit the flashlight sideways hard, then the board moves from the landing site and I'm afraid that then the diode may overheat during prolonged operation. What kind of strong heat transfer adhesives can be?

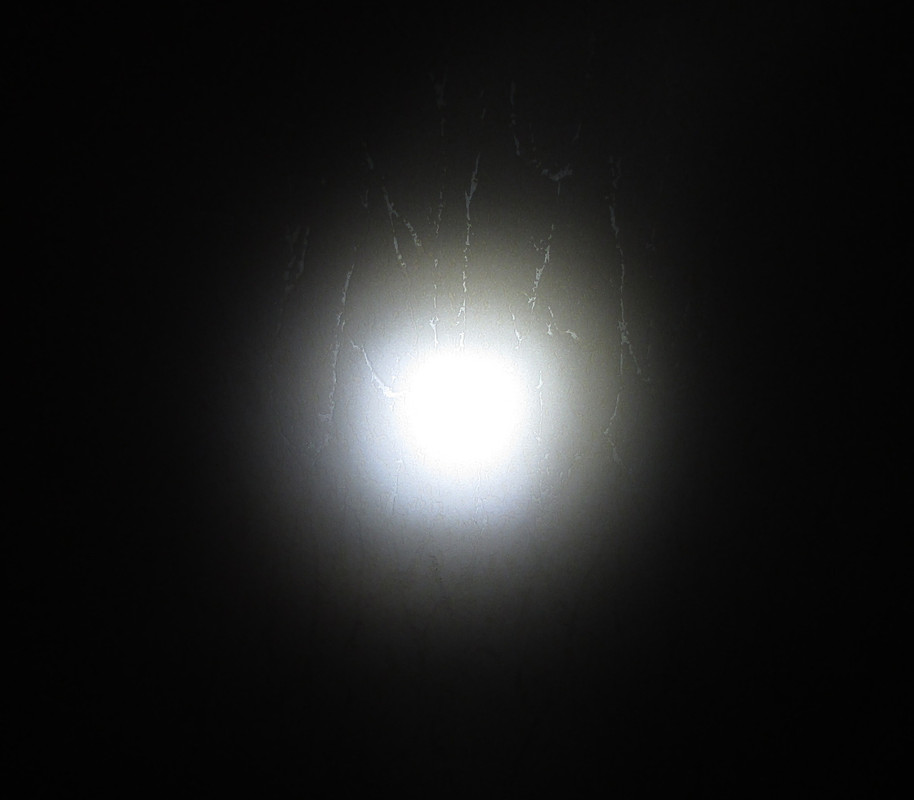

So far, measurements on a 3xC battery are:

XPG2 shaved

4.3 V

0.27 A

lux on 3 m range = ~ 22 level HDS 220 lm SST20

or maybe it makes sense to tie it with insulated wire to an aluminum cooling structure in the same way you tie wooden telegraph poles to a concrete base?

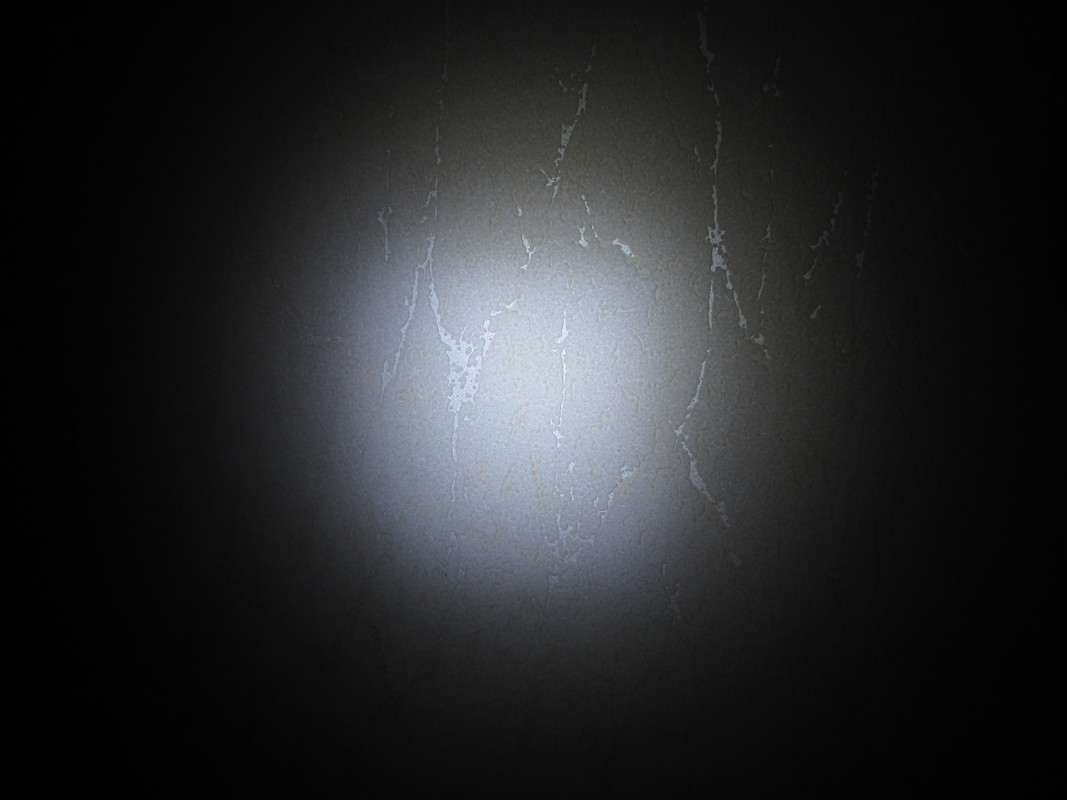

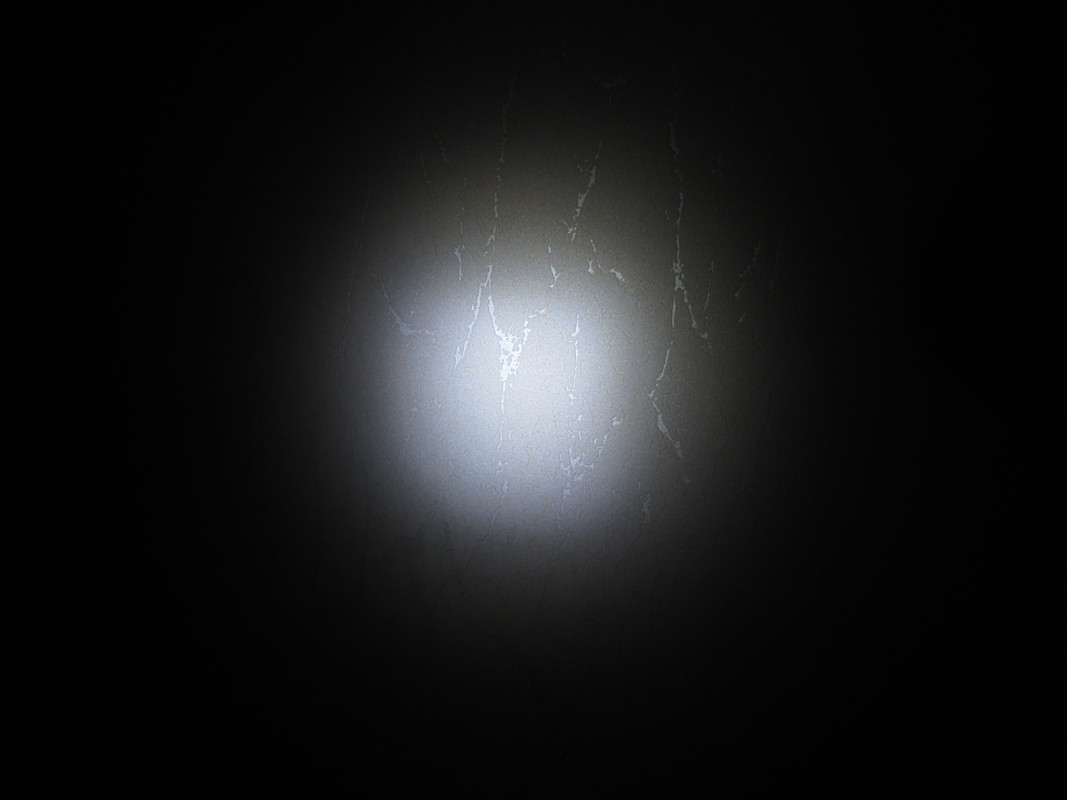

So far, measurements on a 3xC battery are:

XPG2 shaved

4.3 V

0.27 A

lux on 3 m range = ~ 22 level HDS 220 lm SST20

or maybe it makes sense to tie it with insulated wire to an aluminum cooling structure in the same way you tie wooden telegraph poles to a concrete base?