PhotonFanatic

Flashlight Enthusiast

When you've got a driver already installed in an cannister and you are only replacing the LED, there isn't much you can do to improve your lot--you just need good eyes, a steady hand, and good equipment.

But if you are making new modules, then everything is fair game and given my abilities, I prefer to make life as easy as possible for myself.

Hence the attempt at a soldering jig designed merely to help with the soldering of wires onto the LED prior to insertion into a converter module.

First, I wanted to be able to just press the soldering iron against the wire and apply solder when it is hot enough. I didn't want a third hand holding the wire, or the LED. After some thought, feeble though it may be, I decided that soldering the wire onto the leads while the LED was upside down would be easiest. Just needed a jig to pull it off. Lathe to the rescue!

First, I made two bores, one to clear the dome and the other to clear the black plastic encapsulation, yet shallow enough so that the leads would not contact the brass:

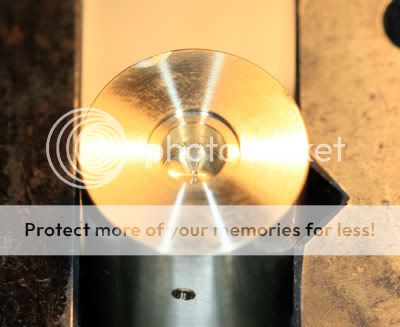

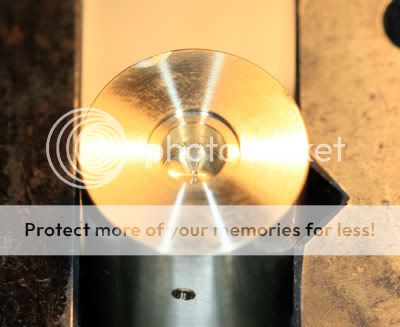

And this is with an LED in place--notice the slight clearance between the leads and the brass body:

Only problem with that is that the LED will lift up when one presses down on the wire on the lead. I had thought about using a rubber band to just hold the led down, and that's what the hole was for--slide a rod through and just loop the band over both ends as well as the LED. To be honest, that may work just fine, but I haven't tried it yet.

Instead, I wanted something that would not only hold the LED down, but also hold the wires in position. So I made a cap to fit over the base, with two holes drilled in the sides for the wires to enter:

Here is a shot with one wire in place:

And here's anothe view of the wire entering the jig:

Tomorrow I'll give it a try and see how it works. Note that in the true PhotonFanatic tradition of never, ever making anything right the first time, that the cap wasn't made perfectly. While doing the final bore to reach the milled cut-outs, I went too deep, mainly because with the piece spinning in the lathe, I couldn't see that I had already reached the right depth! Talk about poor eyesight.

Any comments, suggestions, etc., are welcome. There's always something to improve.

But if you are making new modules, then everything is fair game and given my abilities, I prefer to make life as easy as possible for myself.

Hence the attempt at a soldering jig designed merely to help with the soldering of wires onto the LED prior to insertion into a converter module.

First, I wanted to be able to just press the soldering iron against the wire and apply solder when it is hot enough. I didn't want a third hand holding the wire, or the LED. After some thought, feeble though it may be, I decided that soldering the wire onto the leads while the LED was upside down would be easiest. Just needed a jig to pull it off. Lathe to the rescue!

First, I made two bores, one to clear the dome and the other to clear the black plastic encapsulation, yet shallow enough so that the leads would not contact the brass:

And this is with an LED in place--notice the slight clearance between the leads and the brass body:

Only problem with that is that the LED will lift up when one presses down on the wire on the lead. I had thought about using a rubber band to just hold the led down, and that's what the hole was for--slide a rod through and just loop the band over both ends as well as the LED. To be honest, that may work just fine, but I haven't tried it yet.

Instead, I wanted something that would not only hold the LED down, but also hold the wires in position. So I made a cap to fit over the base, with two holes drilled in the sides for the wires to enter:

Here is a shot with one wire in place:

And here's anothe view of the wire entering the jig:

Tomorrow I'll give it a try and see how it works. Note that in the true PhotonFanatic tradition of never, ever making anything right the first time, that the cap wasn't made perfectly. While doing the final bore to reach the milled cut-outs, I went too deep, mainly because with the piece spinning in the lathe, I couldn't see that I had already reached the right depth! Talk about poor eyesight.

Any comments, suggestions, etc., are welcome. There's always something to improve.

Should I Email it to you? :duck:

Should I Email it to you? :duck:  OK, I`ll send you an Email with a drawing I made of funny money. :nana:

OK, I`ll send you an Email with a drawing I made of funny money. :nana:  :duck:

:duck:  Please count me in if you do decide to make a run.

Please count me in if you do decide to make a run.