I have been working on refining this part now for a while and have made a few protos. I'd like to now share this information and make the loc-line block head part available.

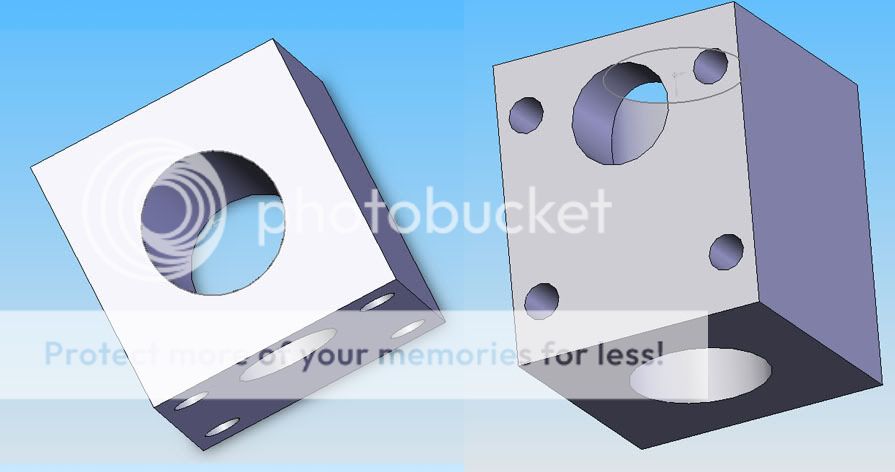

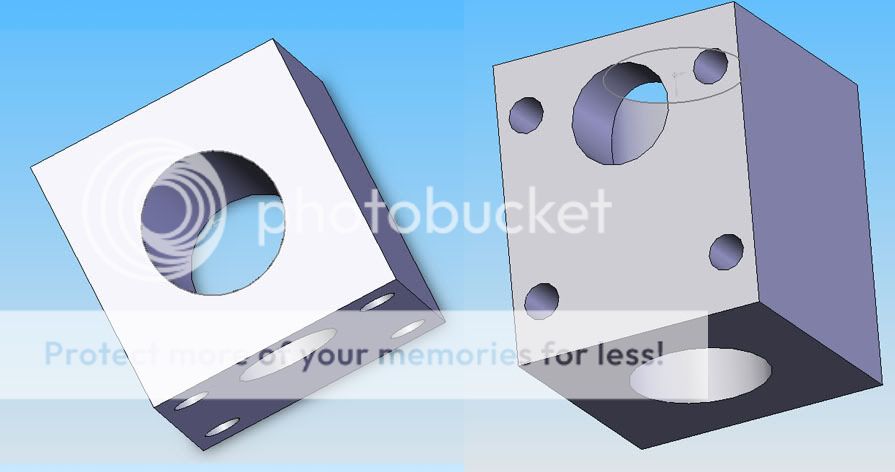

The part originally was drawn up as shown below.

The side port allowed wire to exit the side instead of the top. This additional hole adds a little to the cost and I decided to remove it. you can still drill this hole yourself if you desire this functionality.

The four little holes are for 4-40 threaded mounting or use of a #4 sheet metal screw.

The current version has 4 mounting holes and a threaded hole for 1/8-27 NPS (National Pipe thread straight).

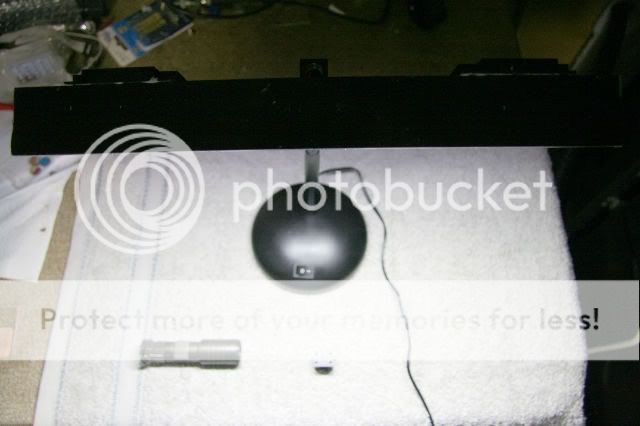

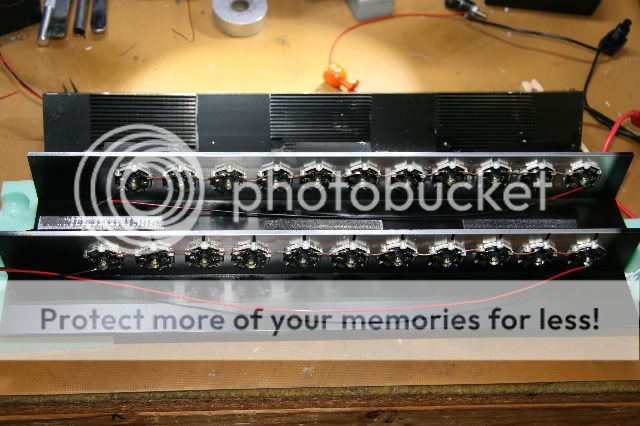

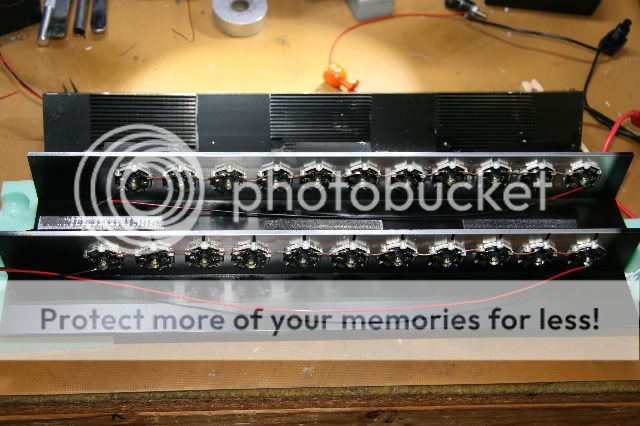

The part allows mounting a light bar like the following to a flex line, loc-line or standard lamp rod. All can be purchased with 1/8-27 threaded ends.

I made the three right angle bracket lights as a test load for the 100W boost converter proto in this thread.

The angle bracket I purchased at the local home depot store. After mounting the Luxeon stars on them I spray painted them black with BBQ flat black which has good thermal characteristics.

Many desk lamps or lamps in general all use 1/8-27 rod components to assemble the lamp. This goes way back. Even the ceiling lights use this thread size. The cap that holds the lamp shade or the glass on ceiling lights are 1/8-27 plastic nuts.

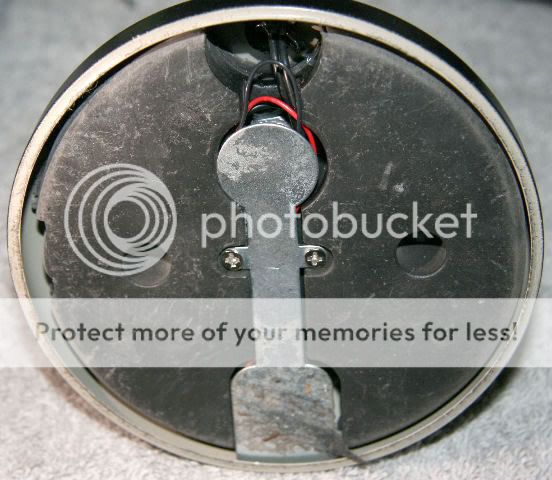

One example of use I found a standard desk lamp that I could see the screw nut inside the lamp housing.

Inside the lamp you can see a nut attachment.

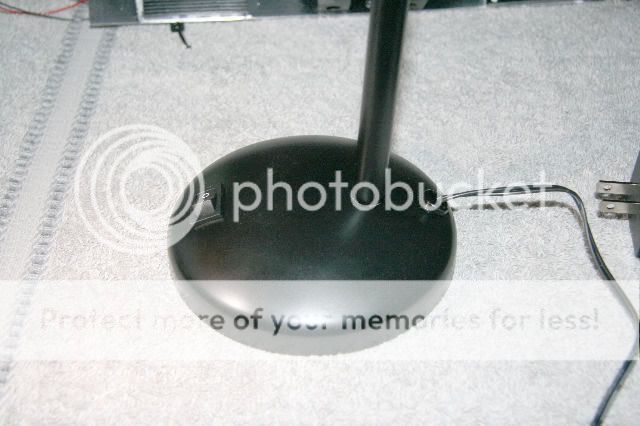

Once the assembly is taken apart you can screw on the llbh (loc-line block head) attached to the L bracket lamp assembly and whoala instant conversion (more or less).

Front view

Rear view

The llbh part is a small part 3/4" square.

Some attachment options.

llbh to loc-line.

Double llbh to add more stability (loc-line can't hold much weight).

llbh to flex line.

I'm sure you have more ideas. I would love to see more ideas of this general purpose part.

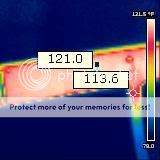

Beam shots to follow...

If you want to drill and tap your own material for 1/8-27 I can suggest getting the tap at Enco here. Don't get the NPT taps. They are tapered and not what you want.

I will post a link the shoppe page when they go online.

Wayne

The part originally was drawn up as shown below.

The side port allowed wire to exit the side instead of the top. This additional hole adds a little to the cost and I decided to remove it. you can still drill this hole yourself if you desire this functionality.

The four little holes are for 4-40 threaded mounting or use of a #4 sheet metal screw.

The current version has 4 mounting holes and a threaded hole for 1/8-27 NPS (National Pipe thread straight).

The part allows mounting a light bar like the following to a flex line, loc-line or standard lamp rod. All can be purchased with 1/8-27 threaded ends.

I made the three right angle bracket lights as a test load for the 100W boost converter proto in this thread.

The angle bracket I purchased at the local home depot store. After mounting the Luxeon stars on them I spray painted them black with BBQ flat black which has good thermal characteristics.

Many desk lamps or lamps in general all use 1/8-27 rod components to assemble the lamp. This goes way back. Even the ceiling lights use this thread size. The cap that holds the lamp shade or the glass on ceiling lights are 1/8-27 plastic nuts.

One example of use I found a standard desk lamp that I could see the screw nut inside the lamp housing.

Inside the lamp you can see a nut attachment.

Once the assembly is taken apart you can screw on the llbh (loc-line block head) attached to the L bracket lamp assembly and whoala instant conversion (more or less).

Front view

Rear view

The llbh part is a small part 3/4" square.

Some attachment options.

llbh to loc-line.

Double llbh to add more stability (loc-line can't hold much weight).

llbh to flex line.

I'm sure you have more ideas. I would love to see more ideas of this general purpose part.

Beam shots to follow...

If you want to drill and tap your own material for 1/8-27 I can suggest getting the tap at Enco here. Don't get the NPT taps. They are tapered and not what you want.

I will post a link the shoppe page when they go online.

Wayne

Last edited: