PhotonFanatic

Flashlight Enthusiast

I often like to build custom made converter modules--designed to hold the standard .55" drivers from suppliers like the Sandwich Shoppe and others.

Every once in a while though, I've put a driver in, only to find that the LED won't light. Damn! Especially if one is potting the driver, a failure like that sucks big time.

Recently, I've made a custom copper converter for a custom light and the choice of driver was the GD750, which I've used many times.

This time, though, instead of epoxying the driver in place, I decided to wire it up without the epoxy and then test it. Good thing, as it didn't work. Hmmm.

Yup, check the polarity, the wiring, etc., all was good--so WTF was wrong?

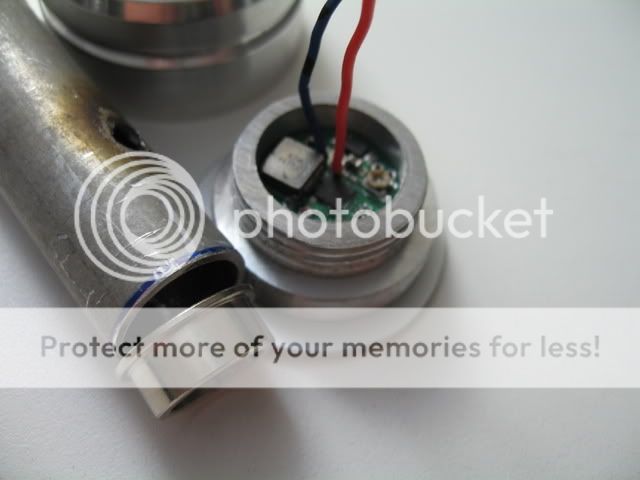

Perhaps this red arrow shows the culprit:

That's awfully close to the edge of the board, too close for me, and I'm pretty sure it was touching the copper converter housing.

So I decided to isolate the driver so that it wouldn't contact the module anywhere. First I needed to bore out the copper converter module so that I could insert the isolating sleeve:

The nominal diameter of the GD750 is 14mm, so I bored out to 16mm and took that down to 1.62mm so that the board would be flush with the module when installed. I also bored another step, 15mm in diameter and about 5mm from the edge of the converter.

Next I made a polycarbonate sleeve:

That matched the bores that I had just done in the copper module, so that this sleeve should just slide in place.

And the interior of the sleeve was bored to fit the GD750 board:

So for the final installation, I epoxied the sleeve in place first, and then epoxied the driver into the sleeve. Now there was no way that any component could reach the copper module:

And you know what? It worked perfectly.

Every once in a while though, I've put a driver in, only to find that the LED won't light. Damn! Especially if one is potting the driver, a failure like that sucks big time.

Recently, I've made a custom copper converter for a custom light and the choice of driver was the GD750, which I've used many times.

This time, though, instead of epoxying the driver in place, I decided to wire it up without the epoxy and then test it. Good thing, as it didn't work. Hmmm.

Yup, check the polarity, the wiring, etc., all was good--so WTF was wrong?

Perhaps this red arrow shows the culprit:

That's awfully close to the edge of the board, too close for me, and I'm pretty sure it was touching the copper converter housing.

So I decided to isolate the driver so that it wouldn't contact the module anywhere. First I needed to bore out the copper converter module so that I could insert the isolating sleeve:

The nominal diameter of the GD750 is 14mm, so I bored out to 16mm and took that down to 1.62mm so that the board would be flush with the module when installed. I also bored another step, 15mm in diameter and about 5mm from the edge of the converter.

Next I made a polycarbonate sleeve:

That matched the bores that I had just done in the copper module, so that this sleeve should just slide in place.

And the interior of the sleeve was bored to fit the GD750 board:

So for the final installation, I epoxied the sleeve in place first, and then epoxied the driver into the sleeve. Now there was no way that any component could reach the copper module:

And you know what? It worked perfectly.