I have asked too many questions without giving back and my conscience is eating me. So here is my build so far...

Here are the criteria for my build:

- Handy (Mag D is acceptable)

- powerful for video (P7 "seems" ok)

- not much machining required. (I only have a hobby drill and hand tools)

Work required :

- Seals and waterproofing:

1) Epoxy Putty for lens (see pic)

2) UK SL4 O-ring used for tail-cap o-ring

3) off-the-shelf o-ring for the bezel

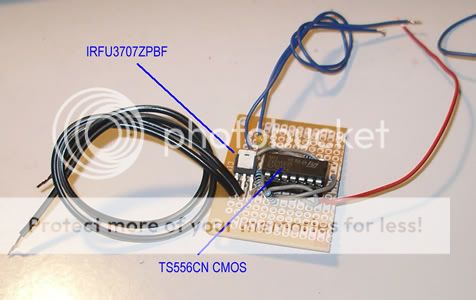

4) JB weld for piezo and cut-down barrel.

- Light and control

5) heatsink from local PC shop (See pic)

6) SSC P7 CSXO and D Li-ION from KD

7) SKU 07612 from DX for control

8) SKU 01886 from DX to supply up to 2.4A (after 4months of waiting it is being delivered as of this post)

- Switch

9) 16mm Piezo (See pic)

10) using a modified Bill Bowden toggle circuit. (Having difficulties here now)

And here is the work so far since June.....

Putty Epoxy is used to seal the lens to the bezel.

Lens is a 4.5mm thick Acrylic (3.5mm at the edge for better thread on bezel)

The switch is on the tail cap. And this screw-in contact is what i came up with. Springs and contacts salvaged from the stock Mag switch. Separate alu. plate was filed to fit tailcap.

Contacts on tail cap and barrel. Barrel contact plate was tedious to file to fit the tiny step inside the barrel without falling through.

LED on Heatsink on barrel on Lighthead....

Used a heatsink I bought from the local PC shop and filed to size.

Piezo switch on Tailcap.

Here are the criteria for my build:

- Handy (Mag D is acceptable)

- powerful for video (P7 "seems" ok)

- not much machining required. (I only have a hobby drill and hand tools)

Work required :

- Seals and waterproofing:

1) Epoxy Putty for lens (see pic)

2) UK SL4 O-ring used for tail-cap o-ring

3) off-the-shelf o-ring for the bezel

4) JB weld for piezo and cut-down barrel.

- Light and control

5) heatsink from local PC shop (See pic)

6) SSC P7 CSXO and D Li-ION from KD

7) SKU 07612 from DX for control

8) SKU 01886 from DX to supply up to 2.4A (after 4months of waiting it is being delivered as of this post)

- Switch

9) 16mm Piezo (See pic)

10) using a modified Bill Bowden toggle circuit. (Having difficulties here now)

And here is the work so far since June.....

Putty Epoxy is used to seal the lens to the bezel.

Lens is a 4.5mm thick Acrylic (3.5mm at the edge for better thread on bezel)

The switch is on the tail cap. And this screw-in contact is what i came up with. Springs and contacts salvaged from the stock Mag switch. Separate alu. plate was filed to fit tailcap.

Contacts on tail cap and barrel. Barrel contact plate was tedious to file to fit the tiny step inside the barrel without falling through.

LED on Heatsink on barrel on Lighthead....

Used a heatsink I bought from the local PC shop and filed to size.

Piezo switch on Tailcap.

Last edited: