photonwave

Newly Enlightened

I cannot find a suitable cable to save this project! What I have is a bunch of T8 style LED tubes. The ends are just like regular T8 tubes, but both ends have the dual prongs that act as a single conductor. This allows for a parallel or serial configuration.

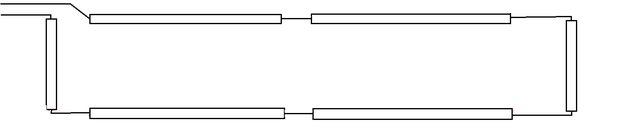

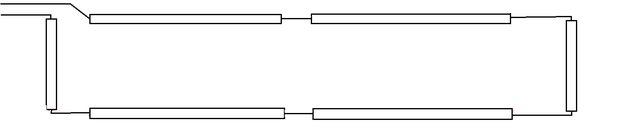

So I'm trying to run these in a serial configuration. Picture included to give an idea.

Any clues where I could get some simple silicone-shrouded cables that can hook up T8-LEDs end to end? The shroud should ideally extend 1cm over the tube. I try looking everywhere and the closest thing I can find even RESEMBLING what I need is way too much for what I need. I just need a simple connector cable, not a whole gangable rig! I cannot use regular T8 fixtures like I'd normally use, I must have water-proof shrouded ends.

So I'm trying to run these in a serial configuration. Picture included to give an idea.

Any clues where I could get some simple silicone-shrouded cables that can hook up T8-LEDs end to end? The shroud should ideally extend 1cm over the tube. I try looking everywhere and the closest thing I can find even RESEMBLING what I need is way too much for what I need. I just need a simple connector cable, not a whole gangable rig! I cannot use regular T8 fixtures like I'd normally use, I must have water-proof shrouded ends.

Last edited: