My third ground up build:

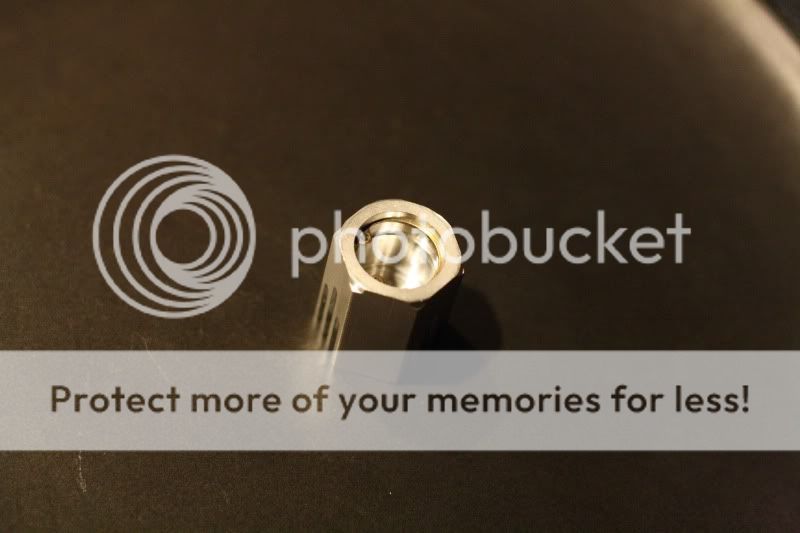

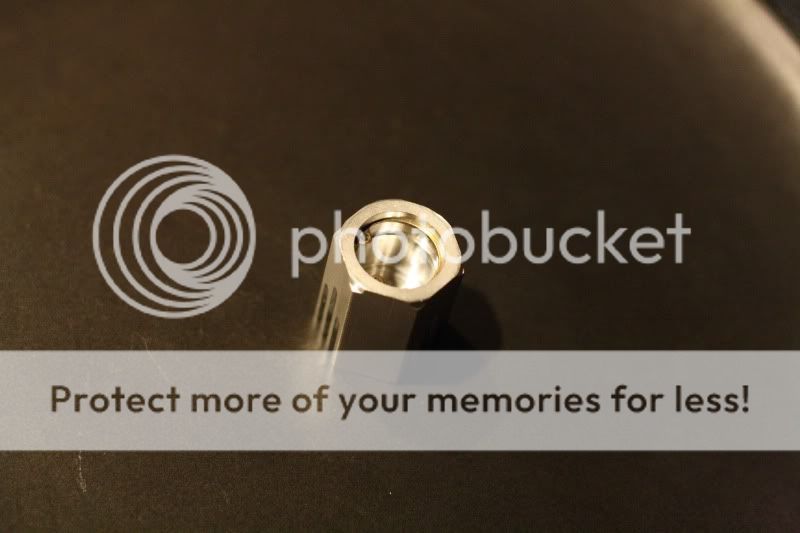

Finished the host for the single XP-G unit. Both my triple and single have shipped, so I guess I'd better get on the stick and get some anodizing done.

It has a double stepped flat bottom hole b/c the MCPCB is 14.6mm, Tina optics are 16.1, and the Lens and O-Ring are 17mm. Snap ring is 19mm.

This one uses a snap ring to retain the guts. I'm going to get a less obtrusive ring...but this was all I had available at the moment.

Size:

And compared to the MS:

Now I gotta build a mount for the single.

Finished the host for the single XP-G unit. Both my triple and single have shipped, so I guess I'd better get on the stick and get some anodizing done.

It has a double stepped flat bottom hole b/c the MCPCB is 14.6mm, Tina optics are 16.1, and the Lens and O-Ring are 17mm. Snap ring is 19mm.

This one uses a snap ring to retain the guts. I'm going to get a less obtrusive ring...but this was all I had available at the moment.

Size:

And compared to the MS:

Now I gotta build a mount for the single.