Guys, I am playing around with some MagLites and I know I can stack 2 of the DX lenses in there. Question is, how deep have you guys taken your dual DX lens Mags? Pack, I know you will have some say on this...

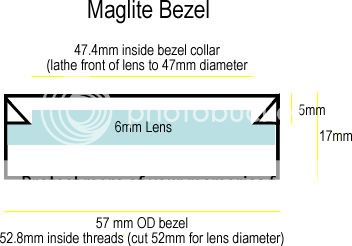

What I want to do is to have some custom cut lenses that will be the thickness of 2 DX lenses out of boro glass. I want to be able to hit 300-350' without cracking and I am wondering whether a lens that is a bit larger than 1/8" will stand up to that psi.

Thanks

What I want to do is to have some custom cut lenses that will be the thickness of 2 DX lenses out of boro glass. I want to be able to hit 300-350' without cracking and I am wondering whether a lens that is a bit larger than 1/8" will stand up to that psi.

Thanks