Battery Guy

Enlightened

[Note for the reader: If you have not been following this thread from the beginning, I feel obliged to warn you that it gets pretty confusing and that there is no clear resolution to the original question on the effect of charge rate on high rate discharge. The problem was that during the testing of new Elite 1700 cells, we ultimately discovered that there has been a significant decrease in high rate (10 A) discharge performance compared to older versions. Unfortunately, this change in the Elite 1700 performance has made pursuing this topic somewhat moot.

That being said, there is a lot of interesting discussion and test data in this thread, so please feel free to read it. Just be forewarned that you are likely not going to get the information that the thread title suggestions.

Cheers,

Battery Guy]

Greetings Everyone

The topic of this thread came out of an off topic discussion that started in a separate thread on chargers. There is an assumption among many Elite 1700 users that in order to get the best high discharge rate performance from these cells, that they should be also be charged at a high rate, ~2C. Obviously, if any NiMH cell is charged fast and used "hot off the charger", it will perform better at high rate. However, the anecdotal evidence suggests that there is more to it than that, and that even if a rapidly charged Elite 1700 cell is allowed to cool sufficiently to room temperature, that it will perform better at high rate if charged fast.

I for one voiced skepticism of this hypothesis, so LuxLuthor, SilverFox, 45/70 and I agreed upon a simple test. I would take a new Elite 1700 cell, charge it at 0.1C for 16 hours, let it rest for one hour, then discharge it at a high rate. I would then take that same cell, charge it at 2C and discharge it at the same rate.

Seems simple enough, right? Well, if you are reading this post for an answer to the question, then you can stop now, because I don't have one. It turns out that this issue may be a bit more complicated than initially thought. I am starting this thread because I thought that some of you might be interested in seeing the results as they come in, and voice opinions as to how the experimental procedure might be modified to make the results more meaningful.

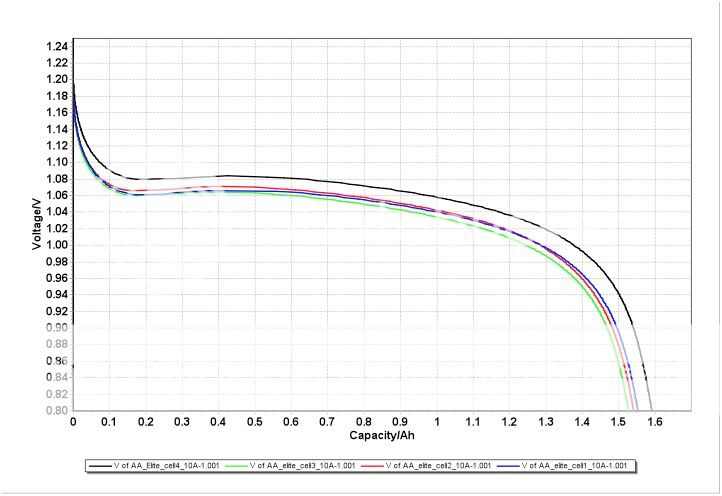

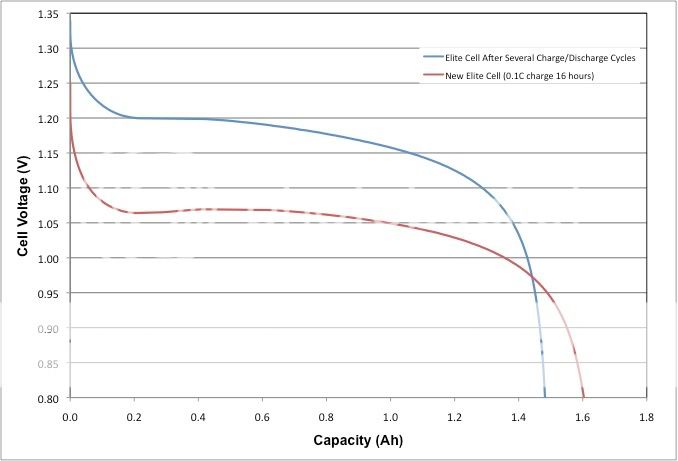

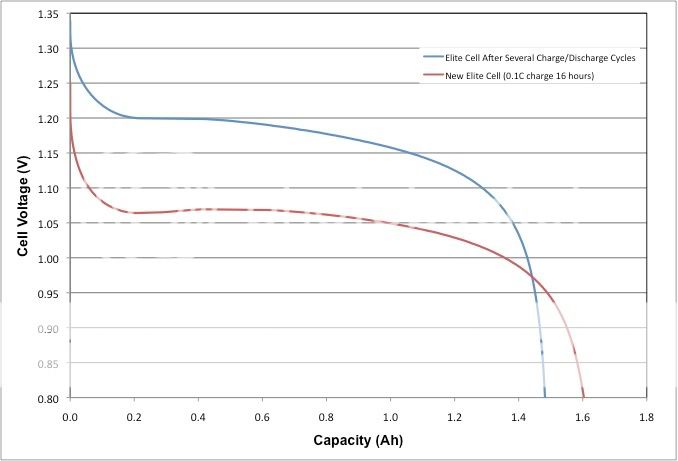

For those of you still with me, you will be interested to know that I completed the first part of the experiment. I took a random, brand new, Elite 1700 cell that I received in the mail from cheapbatterypacks.com on Monday. I discharged the cell at .5 A to bring it to 0 % SOC, and then charged it at 0.170 mA (0.1C) for 16 hours, let it rest for one hour, then discharged it at 10 amps to a 0.8 V cut-off. The discharge curve is shown in the plot below, along with a 10 amp discharge curve for a different Elite 1700 cell that I tested last week and posted the results from in this thread. Keep in mind that both of these cells were discharged at 10 amps on the same instrument using spot welded nickel leads.

For clarification purposes, here are the differences between the two cells:

1.) New Elite Cell (let's call it Cell A, the red line in the plot above) was unused prior to testing. It was discharged at 0.5 amps to 0.8 V, charged at 0.17 amps (0.1C) for 16 hours, rested for 1 hour, discharged at 10 amps to 0.8 V.

2.) Elite cell after several charge discharge cycles (let's call it Cell B, the blue line in the plot above) was unused prior to testing. It was charged at 2 amps on each cycle, rested for 30 minutes, and discharged from 1 amp to 10 amps in 1 amp increments. The discharge curve shown above is for the 10th discharge at 10 amps.

I was shocked by the difference in performance. Unfortunately, the only conclusion that I can draw from this result is that if you get a new Elite 1700 cell, don't expect to get good high rate performance initially with a slow charge.

It might be that Cell A was simply not broken in. Or it might be that Cell B has better high rate performance because it was charged several times at a higher current (2 amps).

I fear that if I continue the experiment as originally devised that we will still not know the real answer. If I now charge Cell A at 2C, then discharge it at 10 A and it performs better, we won't know if the performance improvement comes from the faster charging, or if the additional cycling is helping it to break in.

So I have changed the experimental procedure. As a write this, Cell A is being charged a second time at 0.1C for 16 hours. At the end of that charge, I am discharging it at 1.7 amps (1C) to 0.8 V, followed by holding it at 0.8 V until the discharge current tapers to <0.05 amps (this is essentially the opposite of a CC/CV charge, and is a fast way to completely discharge the cell). Cell A will then be recharged at 0.1C for 16 hours, followed by a 10 amp discharge. I will repeat this process until there is no change in the 10 amp performance. At that point, I will assume that the cell is "broken-in", and will charge it at 2C followed by a 10 amp discharge.

I will continue to post results as they come in. We can then decide if the experiment is conclusive, or if it needs to be repeated with some modification.

As you can see, I am now on a mission to determine once and for all if there is an effect of charge rate on the high current discharge performance of these cells. These initial results have me confused. I don't like to be confused.

As always, suggestions are welcome.

Cheers...and stay tuned!

BG

That being said, there is a lot of interesting discussion and test data in this thread, so please feel free to read it. Just be forewarned that you are likely not going to get the information that the thread title suggestions.

Cheers,

Battery Guy]

Greetings Everyone

The topic of this thread came out of an off topic discussion that started in a separate thread on chargers. There is an assumption among many Elite 1700 users that in order to get the best high discharge rate performance from these cells, that they should be also be charged at a high rate, ~2C. Obviously, if any NiMH cell is charged fast and used "hot off the charger", it will perform better at high rate. However, the anecdotal evidence suggests that there is more to it than that, and that even if a rapidly charged Elite 1700 cell is allowed to cool sufficiently to room temperature, that it will perform better at high rate if charged fast.

I for one voiced skepticism of this hypothesis, so LuxLuthor, SilverFox, 45/70 and I agreed upon a simple test. I would take a new Elite 1700 cell, charge it at 0.1C for 16 hours, let it rest for one hour, then discharge it at a high rate. I would then take that same cell, charge it at 2C and discharge it at the same rate.

Seems simple enough, right? Well, if you are reading this post for an answer to the question, then you can stop now, because I don't have one. It turns out that this issue may be a bit more complicated than initially thought. I am starting this thread because I thought that some of you might be interested in seeing the results as they come in, and voice opinions as to how the experimental procedure might be modified to make the results more meaningful.

For those of you still with me, you will be interested to know that I completed the first part of the experiment. I took a random, brand new, Elite 1700 cell that I received in the mail from cheapbatterypacks.com on Monday. I discharged the cell at .5 A to bring it to 0 % SOC, and then charged it at 0.170 mA (0.1C) for 16 hours, let it rest for one hour, then discharged it at 10 amps to a 0.8 V cut-off. The discharge curve is shown in the plot below, along with a 10 amp discharge curve for a different Elite 1700 cell that I tested last week and posted the results from in this thread. Keep in mind that both of these cells were discharged at 10 amps on the same instrument using spot welded nickel leads.

For clarification purposes, here are the differences between the two cells:

1.) New Elite Cell (let's call it Cell A, the red line in the plot above) was unused prior to testing. It was discharged at 0.5 amps to 0.8 V, charged at 0.17 amps (0.1C) for 16 hours, rested for 1 hour, discharged at 10 amps to 0.8 V.

2.) Elite cell after several charge discharge cycles (let's call it Cell B, the blue line in the plot above) was unused prior to testing. It was charged at 2 amps on each cycle, rested for 30 minutes, and discharged from 1 amp to 10 amps in 1 amp increments. The discharge curve shown above is for the 10th discharge at 10 amps.

I was shocked by the difference in performance. Unfortunately, the only conclusion that I can draw from this result is that if you get a new Elite 1700 cell, don't expect to get good high rate performance initially with a slow charge.

It might be that Cell A was simply not broken in. Or it might be that Cell B has better high rate performance because it was charged several times at a higher current (2 amps).

I fear that if I continue the experiment as originally devised that we will still not know the real answer. If I now charge Cell A at 2C, then discharge it at 10 A and it performs better, we won't know if the performance improvement comes from the faster charging, or if the additional cycling is helping it to break in.

So I have changed the experimental procedure. As a write this, Cell A is being charged a second time at 0.1C for 16 hours. At the end of that charge, I am discharging it at 1.7 amps (1C) to 0.8 V, followed by holding it at 0.8 V until the discharge current tapers to <0.05 amps (this is essentially the opposite of a CC/CV charge, and is a fast way to completely discharge the cell). Cell A will then be recharged at 0.1C for 16 hours, followed by a 10 amp discharge. I will repeat this process until there is no change in the 10 amp performance. At that point, I will assume that the cell is "broken-in", and will charge it at 2C followed by a 10 amp discharge.

I will continue to post results as they come in. We can then decide if the experiment is conclusive, or if it needs to be repeated with some modification.

As you can see, I am now on a mission to determine once and for all if there is an effect of charge rate on the high current discharge performance of these cells. These initial results have me confused. I don't like to be confused.

As always, suggestions are welcome.

Cheers...and stay tuned!

BG

Last edited: