I think I was able to recover everything (pics included) using Tandem's tool and Google cache. Search Google's cache with the syntax:

cache:

https://www.candlepowerforums.com/threads/308569&page=4

Change the page# at the end and search again a page at a time.

-----------------------------------------------------------------------------

PAGE 1:

----------------------------------------------------------------------------- Norealbenefits tooverdrivingXML

Written by

jasonck08 on 01-27-2011 11:14 PM GMT

I've done a little bit of testing with theXML, a bench power supply and an Extech HD450 Lux meter.

So far I've concluded that there appear to be no real benefits to driving an XML past 3A even with proper heatsinking for any length of time!

My heatsink is an Intel CPU heatsink with copper core designed for the Q6600 (95W CPU). The XML is Artic Alumina epoxied onto the copper heatsink.

At 3A in my lab room, I measure the ceiling bounce Lux @ 103 right when I turn on the LED. 5 minutes later I came back and the lux meter was reading 101 Lux. About a 2% drop in 5 minutes.

I then let the heatshink cool down for 5 minutes and started test #2:

At 4A in my lab room I measure a ceiling bounce Lux @ 101 when I cranked the LED to 4A, after 5 minutes, Lux had dropped to 91 Lux! A decrease of about 10%! I turned the current down to 3A and the Lux went up to 98 almost instantly!

Moral of the story. There appears to be no point in driving the XML much past 3A.

Re:Norealbenefits tooverdrivingXML

Written by

mvyrmnd on 01-27-2011 11:49 PM GMT

This is probably why Cree have only specced it to 3A, when it can clearly take more without failure.

The law of diminishing returns is strong with this one...

Re:Norealbenefits tooverdrivingXML

Written by

jasonck08 on 01-28-2011 12:18 AM GMT

The highest lux ratings I got was around 3.2-3.5A But it was only 2-3lux higher than 3A flat. I've already seen several people on these forums makeXML lights with 4-5A drivers. It seems they are using up more power, killing the LED and getting less lumens.

If anybody else has the ability to try to duplicate my scenario, please do so and report here.

Re:Norealbenefits tooverdrivingXML

Written by

Glenn7 on 01-28-2011 01:58 AM GMT

thats interesting thanks for doing that - so even tho the XLM might be more efficient when driven @ 3 amps than an SST50 but over 3 amps the 50 will give you more lumens & the sst50 can be de-domed to give a much better throw as well - so whats the advantage of thexml other than its "new" and everybody has to have one (point:4sevens does a run of xpg S3 and everybody jumped on it for 7 more lumen's which they couldn't see but they could see the extra green tint) yes they are cheaper but you get less as well - to me it looks like a step up from xpg but a step down from the sst or am I missing something?

Re:Norealbenefits tooverdrivingXML

Written by

znomit on 01-28-2011 02:30 AM GMT

Glenn7 said:

- to me it looks like a step up from xpg but a step down from the sst or am I missing something?

It's competing with the MCE and P7 It's competing with the MCE and P7

Re:Norealbenefits tooverdrivingXML

Written by

jasonck08 on 01-28-2011 03:51 AM GMT

Glenn7 said:

to me it looks like a step up from xpg but a step down from the sst or am I missing something?

The The XML is the most efficient LED on the market. It's about 20% more efficient than an XP-G R5. The SST-50 and SST-90 will provide more lumens if they are driven harder than 3A.

Re:Norealbenefits tooverdrivingXML

Written by

Glenn7 on 01-28-2011 04:20 AM GMT

jasonck08 said:

The XML is the most efficient LED on the market. It's about 20% more efficient than an XP-G R5. The SST-50 and SST-90 will provide more lumens if they are driven harder than 3A.

I thought I basically said the same thing? I thought I basically said the same thing?

Dont take this the wrong way, but if you are going to compare efficiency like that then a 5mm led is way more efficent than an xml, it just doesn't put out as much light ether - maybe what I am trying to say is I would rather more lumen's and carry a spare battery or turn the light down a bit for longer run times but have a brighter high.

Re:Norealbenefits tooverdrivingXML

Written by

sn0wBLiND on 01-28-2011 04:43 AM GMT

- Lower Vf, stays regulated longer with a single li-ion and an affordable linear driver in flashlight applications

- Smaller package

- Easier to drive, driver selection for 3A range is a lot bigger than 5A range

- Cheaper, more lm/$

- Smaller die

There are a lot of threads pointing out the differences between these two leds.

Re:Norealbenefits tooverdrivingXML

Written by

Glenn7 on 01-28-2011 05:02 AM GMT

I know all this and I agree.

and you are right, IF you are happy with 400-500 lumens OTF @ 3 amps go with the xml - BUT if you want/need more lumen's than that, according to the OP after 3amps there goes your efficiency, so you might as well go sst that was my point - unless OP has 2 dud leds.

Re:Norealbenefits tooverdrivingXML

Written by

boboweb on 01-28-2011 08:11 AM GMT

Glenn7 said:

I know all this and I agree.

and you are right, IF you are happy with 400-500 lumens OTF @ 3 amps go with the xml - BUT if you want/need more lumen's than that, according to the OP after 3amps there goes your efficiency, so you might as well go sst that was my point - unless OP has 2 dud leds.

If you look at the specifications on paper maybe you are right ,but in practice the things are quite different. The If you look at the specifications on paper maybe you are right ,but in practice the things are quite different. The XM-L provides more lumens at the same current. Regardless of whether the current is under or over 3 amps . At 4 Amps XM-L is clearly superior to SST-50. At higher current the heating of the SST-50 also becomes too high and reduces the effectiveness. So the total possible lumens into Real World are in favor of the XM-L ...

p.s By the way at 3 amps the lumens are much more than 400-500 OTF ...

Re:Norealbenefits tooverdrivingXML

Written by

bigchelis on 01-28-2011 08:42 AM GMT

3A sounds about right.

I can only guess what the current at the LED actually is. We can all do paper math to account for cell sag, driver efficiency, ect..., but we can all hope to be around 3A.

In Direct Drive XM-L 6T builds (2 Surefire L1's for now) I get 4A at the tail, but I am sure the Kroll switch and battery (AW 17670) voltage drops quick and my 4A are more like 3A after all variables are accounted for. I don't have a power supply to confirm this, but its good to see these tests.

Thanks,

bigC

Re:Norealbenefits tooverdrivingXML

Written by

doctaq on 01-28-2011 09:34 AM GMT

i find this kinda hard to beleive that there is absoluteleyno benefit past the exact spec on the datasheet, i wish my ps went beyond 3a

Re:Norealbenefits tooverdrivingXML

Written by

jasonck08 on 01-28-2011 01:52 PM GMT

doctaq said:

i find this kinda hard to beleive that there is absoluteley no benefit past the exact spec on the datasheet, i wish my ps went beyond 3a

I was shocked. I'll try another LED on a new even better heatsink. One designed for a Core i7 930 (130W) CPU. I was shocked. I'll try another LED on a new even better heatsink. One designed for a Core i7 930 (130W) CPU.

Re:Norealbenefits tooverdrivingXML

Written by

palimpsest on 01-28-2011 02:02 PM GMT

Overdriving LED is like overclocking CPU...it is nerdery !

Re:Norealbenefits tooverdrivingXML

Re:Norealbenefits tooverdrivingXML

Written by

superpila on 01-28-2011 02:05 PM GMT

I have modded a Loongsun LX-9012 which came with an SST-50 and a 5A+ Driver, replacing the LED with anXM-L T6. This flashlight is well built and has very good heatsinking. The top 3 levels deliver 5.2, 4.2 and 3 ampere. I have no tools to measure the actual brightness, but on a subjective ceiling bounce test It seems to me that there's no difference between 5.2 and 4.2, but there's a noticeable difference between 4.2 and 3.

I don't have the camera at hand right now but as soon as I get it back I'll post some beamshots.

Re:Norealbenefits tooverdrivingXML

Written by

bao123 on 01-28-2011 06:42 PM GMT

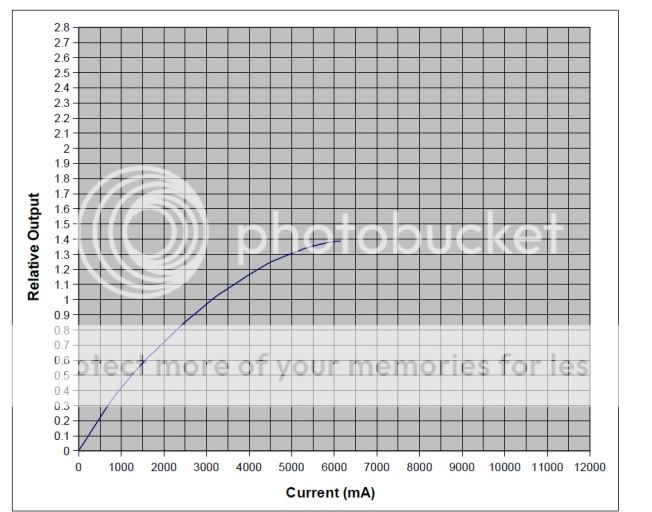

Do retest. I find it extremely hard to believe when looking at the Relative Luminous Flux (%) vs Forward Current (mA) curve from their datasheet. Despite the fact that the curve only goes to 3A, it's unreasonable for the curve to suddenly reach a limit or even dip at that point. Your heatsink has a copper slug, right? I estimate it has at least 200g of aluminum and about the same in copper or a specific heat capacity of roughly 250 J/C. It really shouldn't heat up more than 10 degrees after 5 minutes even with minimal convective heat transfer.

Maybe something else is at work here.

Re:Norealbenefits tooverdrivingXML

Written by

mvyrmnd on 01-28-2011 10:41 PM GMT

This may throw the cat among the pigeons, but check my post (#16)

in this thread for some mathematical verification of these claims.

Personally, I see that the XM-L is brighter at 4A than 3A, but that would appear to be the upper limit of its abilities. More current after that just makes more heat.

Re:Norealbenefits tooverdrivingXML

Written by

jasonck08 on 01-28-2011 11:45 PM GMT

mvyrmnd said:

This may throw the cat among the pigeons, but check my post (#16)

in this thread for some mathematical verification of these claims.

Personally, I see that the XM-L is brighter at 4A than 3A, but that would appear to be the upper limit of its abilities. More current after that just makes more heat.

No offense, but those numbers are completely inaccurate and the numbers past 3A are useless IMO. I've done a second test with a different LED. First one was a T6 2T and 2nd one is a 2D T6. This time I used a much larger heatsink. Results are the same (I'll post them in a few minutes). The XML is brightest at like 3.2 or 3.3A. Any more current and the brightness backs down. If you have proof that an XML at 4A is brighter than at 3A, I'd like to see it. Also, keep in mind that when Cree first announced the XM-L they hinted at a 2A drive current. They bumped up the max current rating shortly before release to 3A, similar to the XP-G increase to 1.5A.

LED current / lumen charts are NEVER linear! There is always a point with a LED where an increase in current yields a decrease in brightness.

Unknown

Written by

mvyrmnd on 01-28-2011 11:51 PM GMT

I agree. Now read post 16 as I suggested.

Re:Norealbenefits tooverdrivingXML

Written by

jasonck08 on 01-29-2011 12:12 AM GMT

mvyrmnd said:

I agree. Now read post 16 as I suggested.

mvyrmnd said:

I sent the data from PCT to my father, who is an engineer and is far better at maths than me

While that chart looks a little more accurate, it doesn't agree with my current testing conclusion that anything past around 3.3A or so results in a decrease in luminous flux. You said you got sent data from PCT. What data? Please provide more information... While that chart looks a little more accurate, it doesn't agree with my current testing conclusion that anything past around 3.3A or so results in a decrease in luminous flux. You said you got sent data from PCT. What data? Please provide more information...

Re:Norealbenefits tooverdrivingXML

Written by

jasonck08 on 01-29-2011 12:43 AM GMT

A graph to represent my 2nd set of tests.

New LED, new wire 22AWG, larger heatsink (edit: Arctic Alumina thermal compound). Same PSU and Lux meter, but positioned slightly different.

Here is a simple bar graph to display the latest test results.

As you can see initial brightness at 3.5A is a tiny bit brighter than @ 3A, but the actual lux reading at 5M was slightly less than the 3 Amp test @ 5M.

Exact readings taken and used for the graph:

3.0A: 97.3 Lux @ 5M 95.8

3.5A: 99.3 Lux @ 5M 95.7

4.0A: 92.0 Lux @ 5M 87.8

Unknown

Written by

mvyrmnd on 01-29-2011 12:57 AM GMT

All of the data points in the graph up to 3A were supplied by Cree from their PCT website. It's linked to in the thread.

The graph is correct, assuming that all other things that can affect luminous flux remain equal. It does not in any way reflect the real output once things like heat are taken into account. Your results are showing the effect of heat on the values in that chart.

Re:Norealbenefits tooverdrivingXML

Written by

csshih on 01-29-2011 01:24 AM GMT

here are my findings.

my experiment used a CPU cooler (Just the heatsink, no fan) - better heatsinking than most lights but indeed Jason is correct.

the chart does not match up with Cree's because they probably have a TEC setup which ensures a 25C Tj.

Re:Norealbenefits tooverdrivingXML

Written by

jasonck08 on 01-29-2011 01:53 AM GMT

mvyrmnd said:

All of the data points in the graph up to 3A were supplied by Cree from their PCT website. It's linked to in the thread.

The graph is correct, assuming that all other things that can affect luminous flux remain equal. It does not in any way reflect the real output once things like heat are taken into account. Your results are showing the effect of heat on the values in that chart.

Well not all of your graphing was from the Cree PCT website, because their tests don't go past 3A, that's why I questioned your source. I thought you were referring to an individual, not the Cree data sheet tool. Also Craig is correct, the data sheets specify a 25C Tj temp, which is not possible at these drive currents (for any length of time), unless one is using a TEC, water cooling, liquid nitrogen, a compressor or some other bazaar setup. The tests you see in this thread are even overly optimistic for flashlight use. What kind of single Well not all of your graphing was from the Cree PCT website, because their tests don't go past 3A, that's why I questioned your source. I thought you were referring to an individual, not the Cree data sheet tool. Also Craig is correct, the data sheets specify a 25C Tj temp, which is not possible at these drive currents (for any length of time), unless one is using a TEC, water cooling, liquid nitrogen, a compressor or some other bazaar setup. The tests you see in this thread are even overly optimistic for flashlight use. What kind of single XM-L flashlight is going to have a heatsink designed to dissipate 130W of heat!

@ Craig

Very nice tests. And your results are similar results to mine. Yours do show a very very slight increase in output when you increase current past 3A, but its obviously not worth the trade in decreased efficiency. The differences will probably vary from LED batch to LED batch and could even vary depending on how well the LED was mounted on the MPCB, the resistance in the connections on the MPCB to the LED.

My tests were done with 18mm 2D, 2T LED's that were mounted on MPCB's from cutter, and your test LED was from another source.

Re:Norealbenefits tooverdrivingXML

Written by

boboweb on 01-29-2011 02:07 AM GMT

superpila said:

I have modded a Loongsun LX-9012 which came with an SST-50 and a 5A+ Driver, replacing the LED with an XM-L T6. This flashlight is well built and has very good heatsinking. The top 3 levels deliver 5.2, 4.2 and 3 ampere. I have no tools to measure the actual brightness, but on a subjective ceiling bounce test It seems to me that there's no difference between 5.2 and 4.2, but there's a noticeable difference between 4.2 and 3.

I don't have the camera at hand right now but as soon as I get it back I'll post some beamshots.

superpila check your PMs

Re:Norealbenefits tooverdrivingXML

Re:Norealbenefits tooverdrivingXML

Written by

mvyrmnd on 01-29-2011 02:15 AM GMT

jasonck08 said:

Well not all of your graphing was from the Cree PCT website, because their tests don't go past 3A, that's why I questioned your source. I thought you were referring to an individual, not the Cree data sheet tool. Also Craig is correct, the data sheets specify a 25C Tj temp, which is not possible at these drive currents (for any length of time), unless one is using a TEC, water cooling, liquid nitrogen, a compressor or some other bazaar setup.

You seem to say this as though I haven't already pointed out numerous times that my graph was an exercise in mathematics. My graph was a You seem to say this as though I haven't already pointed out numerous times that my graph was an exercise in mathematics. My graph was a

theoretical extrapolation of the numbers from the Cree website. The values above 3A were

calculated by performing various mathematical functions on the curve that was formed by Cree's data.

I have, once again, pointed out numerous times that these number are only possible if all factors remain equal, which very obviously they can't.

I'm not here to argue with you. Your results are a result of real-world testing, and observation always trumps theory. I was approaching the same result from a different perspective, sans the effect of heat on emitter efficiency.

If you compare my theoretical graph to your measured charts, they're only really different in the final few % at the top of the curve. This is where the output loss due to heat outweighs any extra lumens earned from the increase of current. If anything we should combine out results to get a better indication of the true impact of heat on these emitters.

Re:Norealbenefits tooverdrivingXML

Written by

Walterk on 01-29-2011 04:23 AM GMT

@csshih: Thats a clear graph !

Do you happen to have Lux measurements in that format from that same testrig?

It would give some comparison to other charts like from mvyrmnd in the other thread and Techjunkies beamshots.

Re:Norealbenefits tooverdrivingXML

Written by

ti-force on 01-29-2011 07:21 AM GMT

I always browse through the Homemade and Modified section and see lights that people claim make huge lumen output numbers based on their calculations using the manufacturers datasheets,(some of them are definitelyoverdriving the emitter/s) and every time I think to myself, "Man! I wish this guy would send this light to me for testing, because I know it doesn't make that amount of light OTF, and I'm almost certain it doesn't hold anywhere near that amount for any decent amount of time, but I never say anything to keep the peace, and they never inquire about sending any of these lights to me.

It's almost like they don't really want to know how bad the output drops lol....

Anyway, I've learned that it's best to stay within the recommended specs of these components, but I guess it really boils down to what you really want. I want a light that holds its output pretty well, but the next man may be completely satisfied if his custom light makes 100 more OTF lumens for .5 seconds

. I've had very good results with these emitters, but I've stayed within spec.

I've modified three different lights with an XM-L T6 flux bin, 2T tint bin emitter. One is a

Quark 123-2 at 2.1A drive current, another is a

Quark 123-2 Turbo at 2.1A drive current, and the last one is a

Maelstrom G5 at 2.8A drive current.

I know this isn't exactly on topic with overdriving these emitters, but I thought these results can be used as a reference in the future for comparison of driving within spec vs driving out of spec. If you don't want my results here please let me know and I'll edit to remove.

My OTF test results taken in my homemade 16" integrating sphere are as follows:

This light is powered by a single AW 17670 protected Li-Ion battery, and it was fully charged for testing.

_______________

123-2 Quark, fully charged AW 17670, SB 2.1A driver High Mode_______________

_________________________1 Sec___________585.5__________________________

________________________30 Sec___________562.4__________________________

_________________________1 Min___________552.7__________________________

_________________________2 Min___________549.1__________________________

_________________________3 Min___________545.5__________________________

This light is powered by a single AW 17670 protected Li-Ion battery, and it was fully charged for testing.

____________

Quark Turbo 123-2, fully charged AW 17670, SB 2.1A driver High Mode_______________

________________________1 Sec_____________613.3_____________________________ _

________________________30 Sec____________585.5______________________________

________________________1 Min_____________578.2_____________________________ _

________________________2 Min_____________572.1_____________________________ _

________________________3 Min_____________566.1_____________________________ _

________________________4 Min_____________564.9_____________________________ _

This light is powered by a single AW 18650, 2600mAh protected Li-Ion battery, and it was fully charged for testing.

_______________

Maelstrom G5, fully charged AW 18650, SB 2.8A driver High Mode_______________

________________________1 Sec_____________739.4__________________________

_______________________30 Sec_____________701.8_________________________

________________________1 Min_____________693.3__________________________

________________________2 Min_____________682.4__________________________

________________________3 Min_____________672.7__________________________

Re:Norealbenefits tooverdrivingXML

Written by

recDNA on 01-29-2011 07:51 AM GMT

Those are all great mods and truly impressive numbers. The one that surprises me a little is the G5. That flashlight was built to dissipate heat so I would think it would have a good heat sink? (you tell me)

Nevertheless it still is losing quite a bit of output over 3 minutes. Is there something about the G5 the prevents efficient transmission of heat from the led to the head then to the body?

Re:Norealbenefits tooverdrivingXML

Written by

ti-force on 01-29-2011 09:21 AM GMT

recDNA said:

Those are all great mods and truly impressive numbers. The one that surprises me a little is the G5. That flashlight was built to dissipate heat so I would think it would have a good heat sink? (you tell me)

Nevertheless it still is losing quite a bit of output over 3 minutes. Is there something about the G5 the prevents efficient transmission of heat from the led to the head then to the body?

Personally I don't feel that it's losing that much output. I always publish the 1 second output like BigC and MrGman, but I always compare starting at 30 seconds because it's much more consistent. If you will notice, the G5 lost the largest amount of light from 1 sec to 30 sec, after that it's very stable.

Here's a quick comparison of the percentage of the total output from 30 seconds to 3 minutes:

The Quark 123-2 is first- 562.4 at 30 sec down to 545.5 at 3 minutes. This is a loss of 16.9 OTF lumens and a total percentage loss of 3%.

The Quark Turbo 123-2 is next- 585.5 at 30 sec down to 566.1 at the 3 minute mark. This is a loss of 19.4 OTF lumens and a total percentage loss of 3.3%. Very close to the 123-2 non-turbo and the additional output can be chocked up due to the larger reflector of the Turbo model.

The G5 is last, now keep in mind that it's being driven at 2.8A while the other 2 are being driven at only 2.1A. 701.8 at 30 seconds down to 672.7 at 3 minutes. This is a loss of 29.1 lumens and a total percentage loss of only 4.15%. So it's really not losing much more than the other two lights, and it's being driven with roughly 30% increase in drive current vs the other two. Also, for roughly a 30% increase in drive current, the gain is only a 20% increase in OTF lumens over the Turbo model, and some of that is merely from the larger reflector of the G5.

-----------------------------------------------------------------------------

PAGE 2:

-----------------------------------------------------------------------------

Re: No real benefits to overdriving XML

Written by

Techjunkie on 01-29-2011 10:09 AM GMT

jasonck08 said:

I've done a little bit of testing with the XML, a bench power supply and an Extech HD450 Lux meter.

So far I've concluded that there appear to be no real benefits to driving an XML past 3A even with proper heatsinking for any length of time!

My heatsink is an Intel CPU heatsink with copper core designed for the Q6600 (95W CPU). The XML is Artic Alumina epoxied onto the copper heatsink.

At 3A in my lab room, I measure the ceiling bounce Lux @ 103 right when I turn on the LED. 5 minutes later I came back and the lux meter was reading 101 Lux. About a 2% drop in 5 minutes.

I then let the heatshink cool down for 5 minutes and started test #2:

At 4A in my lab room I measure a ceiling bounce Lux @ 101 when I cranked the LED to 4A, after 5 minutes, Lux had dropped to 91 Lux! A decrease of about 10%! I turned the current down to 3A and the Lux went up to 98 almost instantly!

Moral of the story. There appears to be no point in driving the XML much past 3A.

Your tests are a bit flawed. The epoxy doesn't allow the LED to shed the heat to the heatsink quickly enough, regardless of how big the heatsink is. You could have it epoxied to the Chrysler building and it wouldn't help. Your tests are a bit flawed. The epoxy doesn't allow the LED to shed the heat to the heatsink quickly enough, regardless of how big the heatsink is. You could have it epoxied to the Chrysler building and it wouldn't help.

To test my own 5A builds I ran them for over 20 minutes each. At the end of those runs the XML at 5A were still noticibly brighter than the same setup at 4.2A. I don't have a lux meter, but the side-by-side comparison is obvious to the naked eye and both the 4.2A and the 5A are using the same reflector.

To say that there is no real benefit is misleading. Does efficiency go way down? Sure it does. Does sevice life go way down? I'm sure it probably does. However, if your build is of hotwire mentality where brightness is king and runtime be damned, then there is definitely a benefit to overdriving the XM-L. You just can't use epoxy. Try drilling and tapping some holes into that heatsink and before fastening the star with at least three screws, use good silver thermal grease instead of epoxy. I think your findings will vary.

Glenn7 said:

thats interesting thanks for doing that - so even tho the XLM might be more efficient when driven @ 3 amps than an SST50 but over 3 amps the 50 will give you more lumens & the sst50 can be de-domed to give a much better throw as well - so whats the advantage of the xml other than its "new" and everybody has to have one (point:4sevens does a run of xpg S3 and everybody jumped on it for 7 more lumen's which they couldn't see but they could see the extra green tint) yes they are cheaper but you get less as well - to me it looks like a step up from xpg but a step down from the sst or am I missing something?

I have a top bin 5700K SST-50 that's been de-domed and at every drive current I've tried, in every reflector I've tried, it's brighter than MC-E and P7 but not XM-L. Similarly, at the same drive current in the same reflector, my XM-L builds are all brigher than my SST-50 builds were, which is why I replaced the SST-50 with XM-L in 3 or 4 or my lights. (Most of my XM-L builds were once SST-50). On a side note, de-doming makes the SST-50 easier to focus, but it also comes at the cost of tint change and reduced lumen output. I have a top bin 5700K SST-50 that's been de-domed and at every drive current I've tried, in every reflector I've tried, it's brighter than MC-E and P7 but not XM-L. Similarly, at the same drive current in the same reflector, my XM-L builds are all brigher than my SST-50 builds were, which is why I replaced the SST-50 with XM-L in 3 or 4 or my lights. (Most of my XM-L builds were once SST-50). On a side note, de-doming makes the SST-50 easier to focus, but it also comes at the cost of tint change and reduced lumen output.

znomit said:

It's competing with the MCE and P7

Hardly. The output of the XM-L is leaps and bounds higher than either of those emitters. I've tried one for one swaps in the same 53mm MOP reflectors at the same 2.8-3.0A drive currrent and every time there was vast improvement. Hardly. The output of the XM-L is leaps and bounds higher than either of those emitters. I've tried one for one swaps in the same 53mm MOP reflectors at the same 2.8-3.0A drive currrent and every time there was vast improvement.

sn0wBLiND said:

- Lower Vf, stays regulated longer with a single li-ion and an affordable linear driver in flashlight applications

- Smaller package

- Easier to drive, driver selection for 3A range is a lot bigger than 5A range

- Cheaper, more lm/$

- Smaller die

There are a lot of threads pointing out the differences between these two leds.

Thank you! Thank you!

Re: No real benefits to overdriving XML

Written by

jirik_cz on 01-29-2011 11:31 AM GMT

Glenn7 said:

so even tho the XLM might be more efficient when driven @ 3 amps than an SST50 but over 3 amps the 50 will give you more lumens

XM-L at 3A has more lumens than SST-50 at 4A (and probably as much as SST-50 at 5A)! At least from the comparison of Olight M31/M3X and Thrunite Catapult with SST-50 and XM-L. XM-L at 3A has more lumens than SST-50 at 4A (and probably as much as SST-50 at 5A)! At least from the comparison of Olight M31/M3X and Thrunite Catapult with SST-50 and XM-L.

Also XM-L throws further than SST-50 in the same reflector.

Glenn7 said:

& the sst50 can be de-domed to give a much better throw as well

You can de-dome XM-L as well... You can de-dome XM-L as well...

Re: No real benefits to overdriving XML

Written by

saabluster on 01-29-2011 02:42 PM GMT

jasonck08 said:

I've done a little bit of testing with the XML, a bench power supply and an Extech HD450 Lux meter.

So far I've concluded that there appear to be no real benefits to driving an XML past 3A even with proper heatsinking for any length of time!

.... The XML is Artic Alumina epoxied onto the copper heatsink.

Congratulations! You have successfully demonstrated how ill-advised it is to use epoxy on these mega-output LEDs. The problem is your setup not the LED. Congratulations! You have successfully demonstrated how ill-advised it is to use epoxy on these mega-output LEDs. The problem is your setup not the LED.

Otherwise you are asking me to believe that Cree rated these right up to the bleeding edge? Not a chance. If you are going to do extreme driving it should be soldered directly to a copper heatspreader(not mcpcb) and can then be epoxied down from there.

Re: No real benefits to overdriving XML

Written by

jasonck08 on 01-29-2011 02:50 PM GMT

saabluster said:

Congratulations! You have successfully demonstrated how ill-advised it is to use epoxy on these mega-output LEDs.

Incorrect. My second test was done with Arctic Alumina thermal compound. I'll try Arctic silver next and see if it makes a difference. Incorrect. My second test was done with Arctic Alumina thermal compound. I'll try Arctic silver next and see if it makes a difference.

Techjunkie said:

Your tests are a bit flawed. The epoxy doesn't allow the LED to shed the heat to the heatsink quickly enough, regardless of how big the heatsink is. You could have it epoxied to the Chrysler building and it wouldn't help.

To test my own 5A builds I ran them for over 20 minutes each. At the end of those runs the XML at 5A were still noticibly brighter than the same setup at 4.2A. I don't have a lux meter, but the side-by-side comparison is obvious to the naked eye and both the 4.2A and the 5A are using the same reflector.

My second set of tests were done without thermal epoxy. Instead arctic alumina thermal compound was used. Later I'll do some more tests with artic silver see if my results change. My second set of tests were done without thermal epoxy. Instead arctic alumina thermal compound was used. Later I'll do some more tests with artic silver see if my results change.

If you believe that a 5A light is brither than lets see some proof. Send it to someone with either an integrated sphere or a Lux meter.

How did YOU mount your LED?

jirik_cz said:

XM-L at 3A has more lumens than SST-50 at 4A (and probably as much as SST-50 at 5A)! At least from the comparison of Olight M31/M3X and Thrunite Catapult with SST-50 and XM-L.

4A... Maybe but not at 5A. The SST-50 datasheets say about 1250 lumens @ 5A. The XML @ 3A is brighter than 1250 lumens?? 4A... Maybe but not at 5A. The SST-50 datasheets say about 1250 lumens @ 5A. The XML @ 3A is brighter than 1250 lumens??

Re: No real benefits to overdriving XML

Written by

saabluster on 01-29-2011 03:14 PM GMT

jasonck08 said:

Incorrect. My second test was done with Arctic Alumina thermal compound. I'll try Arctic silver next and see if it makes a difference.

No not incorrect unless you are telling me your own statement is false. No not incorrect unless you are telling me your own statement is false.

jasonck08 said:

The XML is Artic Alumina epoxied onto the copper heatsink.

My statement was not incorrect just not inclusive enough. Yes indeed your other method is woefully short of the job as well. Just do what I said and solder it. My statement was not incorrect just not inclusive enough. Yes indeed your other method is woefully short of the job as well. Just do what I said and solder it.

Re: No real benefits to overdriving XML

Written by

csshih on 01-29-2011 03:18 PM GMT

Walterk said:

@csshih: Thats a clear graph !

Do you happen to have Lux measurements in that format from that same testrig?

It would give some comparison to other charts like from mvyrmnd in the other thread and Techjunkies beamshots.

sorry, no, I just placed a box over the emitter to reflect light back onto the luxmeter - I was only looking for relative ratings. sorry, no, I just placed a box over the emitter to reflect light back onto the luxmeter - I was only looking for relative ratings.

saabluster said:

Just do what I said and solder it.

but wouldn't it be better to get "real-world" data? I'm pretty sure most run of the mill flashlights dont solder their LEDs to the heatsink. but wouldn't it be better to get "real-world" data? I'm pretty sure most run of the mill flashlights dont solder their LEDs to the heatsink.

Re: No real benefits to overdriving XML

Re: No real benefits to overdriving XML

Written by

jasonck08 on 01-29-2011 03:25 PM GMT

saabluster said:

No not incorrect unless you are telling me your own statement is false.

My statement was not incorrect just not inclusive enough. Yes indeed your other method is woefully short of the job as well. Just do what I said and solder it.

First off, I did 2 tests. The first test I specified that I used thermal epoxy. Second test was in post 21. I did not specify that I used arctic alumina thermal compound in that post, but I've edited it now. First off, I did 2 tests. The first test I specified that I used thermal epoxy. Second test was in post 21. I did not specify that I used arctic alumina thermal compound in that post, but I've edited it now.

Secondly, I'd love to solder it. But that's not possible with any soldering iron I have. A heatsink designed to dissipate 130W of heat isn't going to let solder melt and stick with a 40W weller iron. Secondly, I'm not that interested in dealing with bare XML LED's (nor do I have any). 95% of modders and manufacturers only use XML stars, and so far my tests seem to indicate that driving an XML (star mounted) much past 3A is not worth it.

Also, if you soldered directly to the flat copper surface on the CPU heatsink I have, it would short out the LED....

Lastly, if you have the ability to solder an XML to a copper heatsink and do some tests, please be my guest. I'd love to see more results. You may be correct that soldering to a copper heatsink directly will let you push this LED to 4-5A, however that's not very realistic from a general modder / manufacturing standpoint.

Re: No real benefits to overdriving XML

Written by

saabluster on 01-29-2011 03:44 PM GMT

jasonck08 said:

First off, I did 2 tests. The first test I specified that I used thermal epoxy. Second test was in post 21. I did not specify that I used arctic alumina thermal compound in that post, but I've edited it now.

----------

Secondly, I'd love to solder it. But that's not possible with any soldering iron I have. A heatsink designed to dissipate 130W of heat isn't going to let solder melt and stick with a 40W weller iron. Secondly, I'm not that interested in dealing with bare XML LED's (nor do I have any). 95% of modders only use XML stars, and so far my tests seem to indicate that driving an XML star mounted past 3A is not worth it.

Also, if you soldered directly to a single piece of copper wouldn't that short out the LED?

Soldering the whole thing down would certainly cause a short but that is not what I'm referring to. My preferred thickness of copper is 1/8th" thick. From there there are two basic ways to make it work. Use a piece that looks like an hourglass that pinches enough in the middle so as to only touch the electrically isolated center heat pad. The better way is to machine out the area where the elec. pads are and solder them from below. Soldering the whole thing down would certainly cause a short but that is not what I'm referring to. My preferred thickness of copper is 1/8th" thick. From there there are two basic ways to make it work. Use a piece that looks like an hourglass that pinches enough in the middle so as to only touch the electrically isolated center heat pad. The better way is to machine out the area where the elec. pads are and solder them from below.

You are right that that a soldering iron is not up to the task but I assure you you have what you need. Many folks use their stove top to give the required heat. I prefer either my lab oven(convection) or using a heatgun.

Re: No real benefits to overdriving XML

Written by

jirik_cz on 01-29-2011 04:45 PM GMT

jasonck08 said:

4A... Maybe but not at 5A. The SST-50 datasheets say about 1250 lumens @ 5A. The XML @ 3A is brighter than 1250 lumens??

That is what SST50 datasheet says. But there is not a single flashlight that would achieve at least 800 measured lumens with SST-50. That is what SST50 datasheet says. But there is not a single flashlight that would achieve at least 800 measured lumens with SST-50.

Re: No real benefits to overdriving XML

Written by

srfreddy on 01-29-2011 06:15 PM GMT

jirik_cz said:

That is what SST50 datasheet says. But there is not a single flashlight that would achieve at least 800 measured lumens with SST-50.

You've lost the game. You've lost the game.

Seriously, the olight SR-50 puts out 800. Running the XM-L at 5 amps wouldn't get that much.

saabluster said:

Soldering the whole thing down would certainly cause a short but that is not what I'm referring to. My preferred thickness of copper is 1/8th" thick. From there there are two basic ways to make it work. Use a piece that looks like an hourglass that pinches enough in the middle so as to only touch the electrically isolated center heat pad. The better way is to machine out the area where the elec. pads are and solder them from below.

You are right that that a soldering iron is not up to the task but I assure you you have what you need. Many folks use their stove top to give the required heat. I prefer either my lab oven(convection) or using a heatgun.

But who solders a led down IRF's? But who solders a led down IRF's?

Re: No real benefits to overdriving XML

Written by

srfreddy on 01-29-2011 06:21 PM GMT

Techjunkie said:

Your tests are a bit flawed. The epoxy doesn't allow the LED to shed the heat to the heatsink quickly enough, regardless of how big the heatsink is. You could have it epoxied to the Chrysler building and it wouldn't help.

To test my own 5A builds I ran them for over 20 minutes each. At the end of those runs the XML at 5A were still noticibly brighter than the same setup at 4.2A. I don't have a lux meter, but the side-by-side comparison is obvious to the naked eye and both the 4.2A and the 5A are using the same reflector.

To say that there is no real benefit is misleading. Does efficiency go way down? Sure it does. Does sevice life go way down? I'm sure it probably does. However, if your build is of hotwire mentality where brightness is king and runtime be damned, then there is definitely a benefit to overdriving the XM-L. You just can't use epoxy. Try drilling and tapping some holes into that heatsink and before fastening the star with at least three screws, use good silver thermal grease instead of epoxy. I think your findings will vary.

I have a top bin 5700K SST-50 that's been de-domed and at every drive current I've tried, in every reflector I've tried, it's brighter than MC-E and P7 but not XM-L. Similarly, at the same drive current in the same reflector, my XM-L builds are all brigher than my SST-50 builds were, which is why I replaced the SST-50 with XM-L in 3 or 4 or my lights. (Most of my XM-L builds were once SST-50). On a side note, de-doming makes the SST-50 easier to focus, but it also comes at the cost of tint change and reduced lumen output.

Hardly. The output of the XM-L is leaps and bounds higher than either of those emitters. I've tried one for one swaps in the same 53mm MOP reflectors at the same 2.8-3.0A drive currrent and every time there was vast improvement.

Thank you!

I highly doubt the difference in 4.2 and 5 amp drive was noticable. In between ti-forces 2.1 and 2.8 amp xm-l's, the difference in light output was 20%. The human eye is incapable of discerning lower amounts of light difference. I highly doubt the difference in 4.2 and 5 amp drive was noticable. In between ti-forces 2.1 and 2.8 amp xm-l's, the difference in light output was 20%. The human eye is incapable of discerning lower amounts of light difference.

You admitted that a De-dome reduces light output, yet you still compare a dedomed sst-50 to an x-ml. Yes, the XM-L is more efficient than the SST-50 at lower currents, but under a certain threshold, the XP-G becomes even more efficent.

Re: No real benefits to overdriving XML

Written by

Techjunkie on 01-29-2011 06:27 PM GMT

jasonck08 said:

My second set of tests were done without thermal epoxy. Instead arctic alumina thermal compound was used. Later I'll do some more tests with artic silver see if my results change.

Be sure to slide the star around a lot, working it back and forth until the compound is spread micro thin, before securing it in place with at least three screws. Pressure is very important. Be sure to slide the star around a lot, working it back and forth until the compound is spread micro thin, before securing it in place with at least three screws. Pressure is very important.

jasonck08 said:

If you believe that a 5A light is brither than lets see some proof. Send it to someone with either an integrated sphere or a Lux meter.

My lights never leave my posession, not unless they've been gifted or sold. It's not that I think people have bad intentions, it's just that I don't trust anyone to treat them with as much care as I do (especially in transit). Besides, you don't need numbers from an instrument if your eyes tell you that one is brighter than another with the same LED, reflector and focus. Light meters are far more delicate than the human eye. For example, your eye is not likely able to tell the difference between the same light putting out 638 Lumen on start up and 619 Lumen three minutes later, but an instrument can. If your eyes tell you that one drive current is visibly brighter than the other (and all other factors the same), then you can be sure that is certainly brighter (by many lux or lumen). My lights never leave my posession, not unless they've been gifted or sold. It's not that I think people have bad intentions, it's just that I don't trust anyone to treat them with as much care as I do (especially in transit). Besides, you don't need numbers from an instrument if your eyes tell you that one is brighter than another with the same LED, reflector and focus. Light meters are far more delicate than the human eye. For example, your eye is not likely able to tell the difference between the same light putting out 638 Lumen on start up and 619 Lumen three minutes later, but an instrument can. If your eyes tell you that one drive current is visibly brighter than the other (and all other factors the same), then you can be sure that is certainly brighter (by many lux or lumen).

I don't have the benefit of my wife's D-SLR to take a side-by-side photo (it is unfortunately away for built-in flash repair by Mack and may be for months), but I can offer the following two photos that were taken minutes apart at the same exact manual camera settings. Both lights use XM-L on star, mounted in same fashion. Both use Mag Rebel reflectors at the same focus. The camera settings were intended to compare these XM-L lights to lights with other emitters, not each other, and so are not stopped down enough to avoid the pattern of the bricks on the target wall being completely washed out. To compare, pay attention to the brightness of the spill on the wall oven on the left and of the ceiling bounce on the ceiling and floor. It is less obvious in these photos than when I view them side by side in person, but obvious nonetheless that the XM-L at 5A is brigher than at 4.2A. I assure you that the difference is all the more exaggerated when comparing to 3A. Unfortunately, i don't have a pic using the same reflector at 3A.

Target brick wall 30ft from camera and flashlights

Exposure 1/80th second, F3.5, ISO 800, WB 5200K

First up, 5A

Second up, 4.2A

jasonck08 said:

How did YOU mount your LED?

Like this: Like this:

1 3/8" T6061 Aluminum bar tuned to press fit into Mag D neck

Ano. removed from D neck

neck and sink greased with silver thermal grease and sink pressed into neck

4 holes drilled and tapped, 4 brass screws secure silver greased star to sink

Re: No real benefits to overdriving XML

Written by

srfreddy on 01-29-2011 06:41 PM GMT

The spill looks slightly bluer, and that's just about it.

Re: No real benefits to overdriving XML

Written by

AnAppleSnail on 01-29-2011 06:46 PM GMT

srfreddy said:

The spill looks slightly bluer, and that's just about it.

No, it is slightly brighter in the spill, and the overexposed central part is a bit bigger. No way to tell how much brighter the hotspot is on a photo. No, it is slightly brighter in the spill, and the overexposed central part is a bit bigger. No way to tell how much brighter the hotspot is on a photo.

Re: No real benefits to overdriving XML

Written by

Techjunkie on 01-29-2011 06:52 PM GMT

srfreddy said:

You admitted that a De-dome reduces light output, yet you still compare a dedomed sst-50 to an x-ml.

Actually, I compared all my SST-50 lights with domes in tact to the same lights with XM-L. My statement about the de-doming of an SST-50 was in response to the comment that Glenn7 made about the virtues of the SST-50 when de-domed. Actually, I compared all my SST-50 lights with domes in tact to the same lights with XM-L. My statement about the de-doming of an SST-50 was in response to the comment that Glenn7 made about the virtues of the SST-50 when de-domed.

srfreddy said:

The spill looks slightly bluer, and that's just about it.

When I view this page on my monitor, I can barely make out the floor or the stairs in the second photo, but I can see them clearly in the first. Maybe try turning the brightness down on your monitor to see what I'm seeing. When I view this page on my monitor, I can barely make out the floor or the stairs in the second photo, but I can see them clearly in the first. Maybe try turning the brightness down on your monitor to see what I'm seeing.

Re: No real benefits to overdriving XML

Written by

srfreddy on 01-29-2011 06:57 PM GMT

I don't think so, and its also technically impossible. Me thinks its just your imagination.

Re: No real benefits to overdriving XML

Written by

mvyrmnd on 01-29-2011 07:02 PM GMT

Techjunkie said:

When I view this page on my monitor, I can barely make out the floor or the stairs in the second photo, but I can see them clearly in the first. Maybe try turning the brightness down on your monitor to see what I'm seeing.

I can see the difference both on my iPhone and MacBook. The difference is subtle, but it's there. In the second photo you can't see the base of the rack holding the fireplace tools. In both shots the top of the hotspot is level with the speaker on the wall (The top of the hotspot lines up with the center of the large cone), so they're clearly aimed at the same height. I can see the difference both on my iPhone and MacBook. The difference is subtle, but it's there. In the second photo you can't see the base of the rack holding the fireplace tools. In both shots the top of the hotspot is level with the speaker on the wall (The top of the hotspot lines up with the center of the large cone), so they're clearly aimed at the same height.

We're still only talking the difference of a few hundred lumens, at most, but it shows you can still get more out of the XM-L above 3A.

My only XM-L light runs at either 2.8A or 4.2A. I promise you the difference is not only noticeable, but significant. I've only got a photo of it at 4.2A. I'll take a 2.8A shot tonight and post both. (I know we're discussing the 3A limit, but those are the modes it runs at.)

Be sure to slide the star around a lot, working it back and forth until the compound is spread micro thin, before securing it in place with at least three screws. Pressure is very important.

That 95W CPU heatsink you're using? When it's sucking the heat out of your Quad Core chip, it's bolted down with between 40-70lbs clamping force (I don't know the exact Intel specification, but advanced heatsinks that allow you to vary the clamping force all work within those limits). That 95W CPU heatsink you're using? When it's sucking the heat out of your Quad Core chip, it's bolted down with between 40-70lbs clamping force (I don't know the exact Intel specification, but advanced heatsinks that allow you to vary the clamping force all work within those limits).

I imagine that similar clamping force would be required to get the best heat transfer from your LED.

Re: No real benefits to overdriving XML

Written by

srfreddy on 01-29-2011 07:08 PM GMT

Yeah, actually, the stairs are a bit more visible. But 2.8 vs. 4.2, thats adding 50% drive current. There's definitely gonna be a huge light increase, but its just less efficient (i.e. no benefits to me)

Re: No real benefits to overdriving XML

Written by

AnAppleSnail on 01-29-2011 07:18 PM GMT

srfreddy said:

Yeah, actually, the stairs are a bit more visible. But 2.8 vs. 4.2, thats adding 50% drive current. There's definitely gonna be a huge light increase, but its just less efficient (i.e. no benefits to me)

It's 4.2 vs 5, in the most recent post of comparative shots. That's about 20% more current; and to be a perceptible difference must be nearly 20% more light. It's 4.2 vs 5, in the most recent post of comparative shots. That's about 20% more current; and to be a perceptible difference must be nearly 20% more light.

Re: No real benefits to overdriving XML

Written by

srfreddy on 01-29-2011 07:23 PM GMT

I was talking about mvyrmnd's XM-L.

Re: No real benefits to overdriving XML

Written by

srfreddy on 01-29-2011 07:24 PM GMT

mvyrmnd said:

We're still only talking the difference of a few hundred lumens, at most, but it shows you can still get more out of the XM-L above 3A.

That 95W CPU heatsink you're using? When it's sucking the heat out of your Quad Core chip, it's bolted down with between 40-70lbs clamping force (I don't know the exact Intel specification, but advanced heatsinks that allow you to vary the clamping force all work within those limits).

I imagine that similar clamping force would be required to get the best heat transfer from your LED.

Few hundred? Or a few tens of lumens? Few hundred? Or a few tens of lumens?

I would imagine that 3 screws could probably put a good 30 pounds of clamping force down.

Re: No real benefits to overdriving XML

Written by

mvyrmnd on 01-29-2011 07:29 PM GMT

srfreddy said:

I would imagine that 3 screws could probably put a good 30 pounds of clamping force down.

They would, if the OP was using them. They would, if the OP was using them.

AnAppleSnail said:

That's about 20% more current; and to be a perceptible difference must be nearly 20% more light.

srfreddy said:

Few hundred? Or a few tens of lumens?

At 4.2A the XM-L is clear over 1000 Lumens. 20% of 1000 lumens is? At 4.2A the XM-L is clear over 1000 Lumens. 20% of 1000 lumens is?

Re: No real benefits to overdriving XML

Written by

jasonck08 on 01-30-2011 12:54 AM GMT

Test # 3. Same setup only difference is Artic Silver was used and heatsink was tapped and screws were screwed down very tight onto the MPCB.

Numbers:

3.0A 92.8 - 5M 91.6

3.5A - 97.4 - 5M - 94.3

4.0A 92.3 - 5M - 90.1

The heatsinking seemed to allow for currents up to 3.5A without the output decreasing. Efficiency obviously isn't so great at this drive current.

Regardless, I don't know how in heck someone could have a better heatsink setup in a flashlight compared to what I've got posted up there. Core i7 930 stock heatsink designed for up to a 130W load. Artic Silver and pressure mounted with 3 brass screws. Sure, direct soldering it to copper might yield a tiny bit better performance, but again thats not practical for most modders and manufacturers.

Re: No real benefits to overdriving XML

Written by

mvyrmnd on 01-30-2011 01:02 AM GMT

Re: No real benefits to overdriving XML

Re: No real benefits to overdriving XML

Written by

jasonck08 on 01-30-2011 01:31 AM GMT

mvyrmnd said:

I can see the difference both on my iPhone and MacBook. The difference is subtle, but it's there. In the second photo you can't see the base of the rack holding the fireplace tools. In both shots the top of the hotspot is level with the speaker on the wall (The top of the hotspot lines up with the center of the large cone), so they're clearly aimed at the same height.

In this morphed gif, changing from the 4A to 5A picture, you can see the beam lowers several inches, thus providing more light to the fireplace and stairs. The 5A picture the light is positioned a little closer to the wall also. It does appear maybe slightly brighter, but also maybe has more of a blue tint to the side spill. In this morphed gif, changing from the 4A to 5A picture, you can see the beam lowers several inches, thus providing more light to the fireplace and stairs. The 5A picture the light is positioned a little closer to the wall also. It does appear maybe slightly brighter, but also maybe has more of a blue tint to the side spill.

Also you guys are claiming that your lights are brighter at higher currents and that may be true. However are you considering losses in current reaching the LED due to power consumed by the driver? The LED could be only getting 80-90% of the current.

Secondly, its also possible that your LED's are better performers at higher currents than my LED.

----------

@TechJunkie

What driver are you using? What bin are you using? Color and Flux.

Where were your LED's purchased? I may try to get some from the same source as you, to see if my results are any different.

-----------

Just to clarify to everyone, I'm not at all against pushing LED's past their rated current. In fact I was hoping to build a few more XML lights with higher drive currents in the 4-5A range. But so far my personal tests, using the LED's that I have available and heatsinking that far surpasses the performance of anything I could build into a flashlight, its not looking like I'd consider feeding the LED more than 3.5A.

Re: No real benefits to overdriving XML

Written by

mvyrmnd on 01-30-2011 01:40 AM GMT

jasonck08 said:

Also you guys are claiming that your lights are brighter at higher currents and that may be true. However are you considering losses in current reaching the LED due to power consumed by the driver? The LED could be only getting 80-90% of the current.

Mine is driven by a D2flex. At it's highest setting it's Direct Drive, the tailcap current is 4.2A. Being direct drive, I don't think there'd be much loss. The 2nd highest mode is set for 2.8A.

In this morphed gif, changing from the 4A to 5A picture, you can see the beam lower several inches, thus providing more light to the fireplace and stairs.

Well, there you go. I've got to say, as two separate images, on my small screen, they looked the same. That said, after watching your GIF a few times I'm convinced that the spill, at least, is brighter at 5A. Well, there you go. I've got to say, as two separate images, on my small screen, they looked the same. That said, after watching your GIF a few times I'm convinced that the spill, at least, is brighter at 5A.

Re: No real benefits to overdriving XML

Written by

Goldigger on 01-30-2011 02:00 AM GMT

jasonck08 said:

Test # 3. Same setup only difference is Artic Silver was used and heatsink was tapped and screws were screwed down very tight onto the MPCB.

Numbers:

3.0A 92.8 - 5M 91.6

3.5A - 97.4 - 5M - 94.3

4.0A 92.3 - 5M - 90.1

The heatsinking seemed to allow for currents up to 3.5A without the output decreasing. Efficiency obviously isn't so great at this drive current.

Regardless, I don't know how in heck someone could have a better heatsink setup in a flashlight compared to what I've got posted up there. Core i7 930 stock heatsink designed for up to a 130W load. Artic Silver and pressure mounted with 3 brass screws. Sure, direct soldering it to copper might yield a tiny bit better performance, but again thats not practical for most modders and manufacturers.

Could you possibly re-run this test, but with a desk fan blowing at the heatsink and led setup please?

This would be interesting as my lights are all bike lights, so they get wind cooling when im riding..

Re: No real benefits to overdriving XML

Re: No real benefits to overdriving XML

Written by

fyrstormer on 01-30-2011 02:35 AM GMT

There is something I don't see anyone taking into account here. You know the little gold wires that connect the die to the solder terminals? They're about as thick as a hair, if even that much, and you're dumping multiple amps through them. The SST-50 has a lot more little wires than the XM-L has, which means each wire carries less current. That, in turn, means each wire will heat up less and provide less electrical resistance to the current flowing through it. It's entirely possible the XM-L is limited not by the die or its heatsinking capabilities but by the wires that carry the power to the die.

Re: No real benefits to overdriving XML

Written by

MikeAusC on 01-30-2011 02:39 AM GMT

In a constant-current drive situation, a bit of extra voltage drop in the wires will not affect LED output, except for increasing dissipation in the package.

Re: No real benefits to overdriving XML

Written by

boboweb on 01-30-2011 02:41 AM GMT

jasonck08 said:

4A... Maybe but not at 5A. The SST-50 datasheets say about 1250 lumens @ 5A. The XML @ 3A is brighter than 1250 lumens??

I advise you not to over-reliance on the specifications of paper !The "paper" is one thing - real life is another I advise you not to over-reliance on the specifications of paper !The "paper" is one thing - real life is another

-----------------------------------------------------------------------------

-----------------------------------------------------------------------------

PAGE 3:

-----------------------------------------------------------------------------

Re:Norealbenefits tooverdrivingXML

Written by

jasonck08 on 01-30-2011 03:50 AM GMT

fyrstormer said:

There is something I don't see anyone taking into account here. You know the little gold wires that connect the die to the solder terminals? They're about as thick as a hair, if even that much, and you're dumping multiple amps through them. The SST-50 has a lot more little wires than the XM-L has, which means each wire carries less current. That, in turn, means each wire will heat up less and provide less electrical resistance to the current flowing through it. It's entirely possible the XM-L is limited not by the die or its heatsinking capabilities but by the wires that carry the power to the die.

Exactly my thoughts. As the improved heatsinking had very little impact on the results. Also the heatsink is massive and just laughs at a 10W load. The heatsink is just a couple degrees above room temperature after running it for several minutes. The LED bond wires do have limits. It's also possible that some LED's have bondwires that are just a tiny bit larger allowing higher currents. I really think that heat or junction temp is not whats limiting me, its the size of the bond wires and what happens to them as resistance changes when they get more current and heat up. Exactly my thoughts. As the improved heatsinking had very little impact on the results. Also the heatsink is massive and just laughs at a 10W load. The heatsink is just a couple degrees above room temperature after running it for several minutes. The LED bond wires do have limits. It's also possible that some LED's have bondwires that are just a tiny bit larger allowing higher currents. I really think that heat or junction temp is not whats limiting me, its the size of the bond wires and what happens to them as resistance changes when they get more current and heat up.

Overdriving LED's is similar to overclocking CPU's, you'll find chips in a batch that Intel and AMD sell that can be overclocked 30-40% from their stock clock, while another CPU may struggle to get a 20% increase. With awesome heatsinking my XML's limit is about 3.5A before brightness decreases. Others may have LED's capable of slightly higher.

Re:Norealbenefits tooverdrivingXML

Written by

jirik_cz on 01-30-2011 04:09 AM GMT

srfreddy said:

You've lost the game.

Seriously, the olight SR-50 puts out 800. Running the XM-L at 5 amps wouldn't get that much.

I'm talking about I'm talking about real measured lumens. Not manufacturer claims which are often highly inaccurate with SST-50 flashlights.

Re:Norealbenefits tooverdrivingXML

Written by

Walterk on 01-30-2011 06:05 AM GMT

srfreddy said:

I would imagine that 3 screws could probably put a good 30 pounds of clamping force down.

I've had M3 screws in 4-5mm copper and aluminium that didn't hold. I've had M3 screws in 4-5mm copper and aluminium that didn't hold.

Bolt and nuts throughhout the sink would be best but ackward building.

The Cree ring would have helped clamping them down for gleuing.

Has anyone a picture of the underside of a bare XM-L?

Re:Norealbenefits tooverdrivingXML

Written by

Techjunkie on 01-30-2011 10:46 AM GMT

jasonck08 said:

In this morphed gif, changing from the 4A to 5A picture, you can see the beam lowers several inches, thus providing more light to the fireplace and stairs. The 5A picture the light is positioned a little closer to the wall also. It does appear maybe slightly brighter, but also maybe has more of a blue tint to the side spill.

As I said before, these pictures were not meant to show the difference between the two XM-L lights at 4.2 and 5 Amps, but were meant to show a far more obvious difference between XM-L in other reflectors and XM-L vs. other emitters entirely. Bearing that in mind, I think the fact that there is a detectable difference of the additional drive current over 4.2A which is already at the extremely high end demonstrates that the XM-L doesn't top out at 3A. With regard to the tint of the spill, not all emitters have the same tint, even if they are binned the same. My eyes tell me at the extreme edge of the spill which should be the dimmest, the 5A picture is not just "bluer" but is illuminating the handle of that wall oven brigther. As I said before, these pictures were not meant to show the difference between the two XM-L lights at 4.2 and 5 Amps, but were meant to show a far more obvious difference between XM-L in other reflectors and XM-L vs. other emitters entirely. Bearing that in mind, I think the fact that there is a detectable difference of the additional drive current over 4.2A which is already at the extremely high end demonstrates that the XM-L doesn't top out at 3A. With regard to the tint of the spill, not all emitters have the same tint, even if they are binned the same. My eyes tell me at the extreme edge of the spill which should be the dimmest, the 5A picture is not just "bluer" but is illuminating the handle of that wall oven brigther.

jasonck08 said:

Also you guys are claiming that your lights are brighter at higher currents and that may be true. However are you considering losses in current reaching the LED due to power consumed by the driver? The LED could be only getting 80-90% of the current.

Secondly, its also possible that your LED's are better performers at higher currents than my LED.

I wasn't relying on tailcap measurements for the 5A light. For that, a clamp meter was used clamped around the wire from the driver stack to the LED, ensuring the LED is seeing all 5A. For the 4.2A light, AMC7135 regulators maintain the same amperage across the whole circuit and the low Vf of the emitter and the ample headroom of the battery guarantee regulation across most of the discharge. In this case, the battery had been freshly charged. I wasn't relying on tailcap measurements for the 5A light. For that, a clamp meter was used clamped around the wire from the driver stack to the LED, ensuring the LED is seeing all 5A. For the 4.2A light, AMC7135 regulators maintain the same amperage across the whole circuit and the low Vf of the emitter and the ample headroom of the battery guarantee regulation across most of the discharge. In this case, the battery had been freshly charged.

----------

jasonck08 said:

@TechJunkie

What driver are you using? What bin are you using? Color and Flux.

Where were your LED's purchased? I may try to get some from the same source as you, to see if my results are any different.

In the 5A light, I'm using two DX 20330 drivers in parallel, output confirmed with a clamp meter around the LED wires. I've described the 4.2A setup above. In these lights, the emitters were T6 bin purchased in the same batch from KD. Tint bin unknown. In the 5A light, I'm using two DX 20330 drivers in parallel, output confirmed with a clamp meter around the LED wires. I've described the 4.2A setup above. In these lights, the emitters were T6 bin purchased in the same batch from KD. Tint bin unknown.

jasonck08 said:

Just to clarify to everyone, I'm not at all against pushing LED's past their rated current. In fact I was hoping to build a few more XML lights with higher drive currents in the 4-5A range. But so far my personal tests, using the LED's that I have available and heatsinking that far surpasses the performance of anything I could build into a flashlight, its not looking like I'd consider feeding the LED more than 3.5A.

That statement makes perfect sense and is far less provocative than saying that there's That statement makes perfect sense and is far less provocative than saying that there's no benefit to driving an XM-L at over 3 Amps. Weighing the benefit of overdriving an emitter is a matter of personal opinion. Clearly, not everyone would use the same weighting system when designing their own lights. Consider all the effort put forth by members of this forum to design hotdrivers - devices intended to run a bulb within milliwatts of its breaking point. Practical? Surely not. Fun? Hell yeah.

We could debate until the cows come home about "benefits" of overdriving and never reach a conclusion because in the end, the benefit is in the eye of the beholder. But... there is one undeniable statement of truth here, which is that the XM-L can certainly handle much more power than the recommended max spec. By my experience, it takes more abuse than any other high power emitter that's come before it. For me, that makes it the most appealing candidate for driving an LED to the edge - hotwire style - than any other.

Re:Norealbenefits tooverdrivingXML

Written by

fyrstormer on 01-30-2011 01:55 PM GMT

MikeAusC said:

In a constant-current drive situation, a bit of extra voltage drop in the wires will not affect LED output, except for increasing dissipation in the package.

Of course it will affect LED output. The current regulator only "cares" about whether the load at the other end is eating the specified number of amps, not whether those amps are being used to produce light or heat. Those little wires could be glowing hot and the current regulator would be just fine with it -- and with all the light coming off the die, you'd never see the wires even if they did get hot enough to glow. Most likely they aren't, I admit that's an extreme scenario, but if the wires are wasting power producing heat, then that power Of course it will affect LED output. The current regulator only "cares" about whether the load at the other end is eating the specified number of amps, not whether those amps are being used to produce light or heat. Those little wires could be glowing hot and the current regulator would be just fine with it -- and with all the light coming off the die, you'd never see the wires even if they did get hot enough to glow. Most likely they aren't, I admit that's an extreme scenario, but if the wires are wasting power producing heat, then that power

isn't going into the die to produce light. And yet, the current readout will still look correct.

Re:Norealbenefits tooverdrivingXML

Written by

MikeAusC on 01-30-2011 03:17 PM GMT

fyrstormer said:

Of course it will affect LED output. .

fyrstormer said:

but if the wires are wasting power producing heat, then that power isn't going into the die to produce light. And yet, the current readout will still look correct.

You're contradicting yourself here. You're contradicting yourself here.

Yes, more power is going into the whole LED, but the die is still drawing the same power, so producing the same output.

We're talking about a constant-CURRENT supply, not a constant-POWER supply scenario.

Re:Norealbenefits tooverdrivingXML

Written by

IMSabbel on 01-30-2011 06:03 PM GMT

fyrstormer said:

Of course it will affect LED output. The current regulator only "cares" about whether the load at the other end is eating the specified number of amps, not whether those amps are being used to produce light or heat. .

Urg. There is a current through the led. Just because the wires have resistance does not mean the electrons just disappear. Every single electron that heats the bonding wires also goes through the LED. Urg. There is a current through the led. Just because the wires have resistance does not mean the electrons just disappear. Every single electron that heats the bonding wires also goes through the LED.

You will get an increase in Vf, but notice that nobody here is talking about how bright the LED is at 5W, its at 5A.

Re:Norealbenefits tooverdrivingXML

Written by

csshih on 01-30-2011 06:23 PM GMT

on a side note, hah. I broke my XM-L while pushing it. (my psu does ~5A max)

odd. I could not visually see any failures. perhaps the bond wires.. oops!

Re:Norealbenefits tooverdrivingXML

Written by

jasonck08 on 01-30-2011 07:23 PM GMT

csshih said:

on a side note, hah. I broke my XM-L while pushing it. (my psu does ~5A max)

odd. I could not visually see any failures. perhaps the bond wires.. oops!

While on a heatsink? How long did you run it at 5A? While on a heatsink? How long did you run it at 5A?

Techjunkie said:

We could debate until the cows come home about "benefits" of overdriving and never reach a conclusion because in the end, the benefit is in the eye of the beholder. But... there is one undeniable statement of truth here, which is that the XM-L can certainly handle much more power than the recommended max spec. By my experience, it takes more abuse than any other high power emitter that's come before it. For me, that makes it the most appealing candidate for driving an LED to the edge - hotwire style - than any other.

I'd still like to see some other people with Lux meters chime in about driving an I'd still like to see some other people with Lux meters chime in about driving an XML @ 5A. As my XML LED CLEARLY can not take that kind of abuse even with the awesome heatsinking which is better than the heatsink in your XML Light @ 5A. To think that any XML (star mounted) can be driven at 5A I think is absurd. Mine tops out at 3.5A, Craigs seems to top out at 3.5A also and seems to have fried at 5A. Another thing I would like to see is your light (or a similar one) run for 5-10 minutes. We'll see how much the output drops and if the LED begins to blue or if it outright fails.

Re:Norealbenefits tooverdrivingXML

Written by

Techjunkie on 01-30-2011 08:00 PM GMT

jasonck08 said:

Another thing I would like to see is your light (or a similar one) run for 5-10 minutes. We'll see how much the output drops and if the LED begins to blue or if it outright fails.

I ran one for 40-45 minutes straight with a quick 10 second stop about 20 minutes in to change the batteries. I ran one for 40-45 minutes straight with a quick 10 second stop about 20 minutes in to change the batteries. No fail. Still visually brighter than the 4.2A one.

Re:Norealbenefits tooverdrivingXML

Written by

mfj197 on 01-31-2011 09:55 AM GMT

jasonck08 said:

I'd still like to see some other people with Lux meters chime in about driving an XML @ 5A

As would I. Your As would I. Your real-world testing makes good reading, jasonck08, and would seem to imply an XM-L driven at 4A is less bright than one driven at 3A - at least in terms of lux (measured straight in front of the LED I assume?). Does anyone have an integrating sphere to measure lumens?

Is it possible that at these very high overdriven currents the spatial distribution changes and more light is emitted to the sides, but less straight ahead?

Re:Norealbenefits tooverdrivingXML

Written by

HarryN on 01-31-2011 04:01 PM GMT

Hi, thanks for all of the interesting posts and info in this thread. Thermal droop is alive and well in the LED world, and this info continues to prove it.

It isn't that surprising that the droop effect exists, as it has in every power led I have measured over the past 7 - 8 years. What is surprising, is how few people seem to accept its presence. It is difficult to optimize an LED for every situation, so you see firms like Cree optimizing raw output, while firms like Lumileds tend to optimze output under droop conditions. It is not quite the same thing, but it makes them both competitive in the marketplace, even with interestingly different paper specs.

I think it is entirely reasonable to assume that most people do in fact use stars for their applications, as bare SMT LEDs are certainly more challenging to work with for many (not all) people.

The data partly shows why Lumileds engineers make the comment that their LEDs are very competitive (ok, they say better, as you would expect) under real world conditions.

There is nothing like competition to drive improvement.

Re:Norealbenefits tooverdrivingXML

Re:Norealbenefits tooverdrivingXML

Written by

vestureofblood on 01-31-2011 06:08 PM GMT

Jackson08

Thank you so much for doing these tests and sharing your results with us. I love that you also included a picture of your heat sinking setup. I also like the use of a bar graph to show the results.

I think your tests do give a realistic idea of how these LEDs will perform in MOST flashlight.

I will say that for me soldering to a copper slug has proven to be a worth while venture. So far I have only done one XML that way. I still dont think the increase in LUX at 5 min would be huge in a small light, but with a significantly lower junction temp having the led soldered to a maglite size slug may still have a shot at achieving a beneficial increase.

Thanks again for sharing.

Re:Norealbenefits tooverdrivingXML

Written by

ti-force on 01-31-2011 06:17 PM GMT

mfj197 said:

As would I. Your real-world testing makes good reading, jasonck08, and would seem to imply an XM-L driven at 4A is less bright than one driven at 3A - at least in terms of lux (measured straight in front of the LED I assume?). Does anyone have an integrating sphere to measure lumens?