LightSward

Flashlight Enthusiast

I apologize, but one of my photo hosts has unreliable and unstable links, (Facebook based), and this caused a large amount of my photos to vanish over he last few days. Apologize, but with all the photos I posted I'm not able to update all them do to a variety reasons, mostly time.

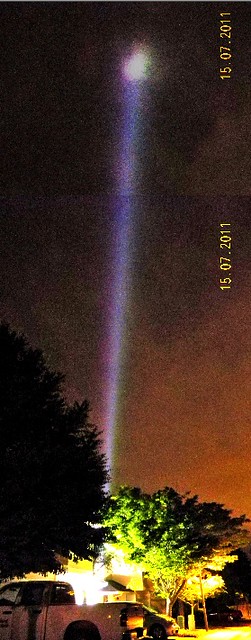

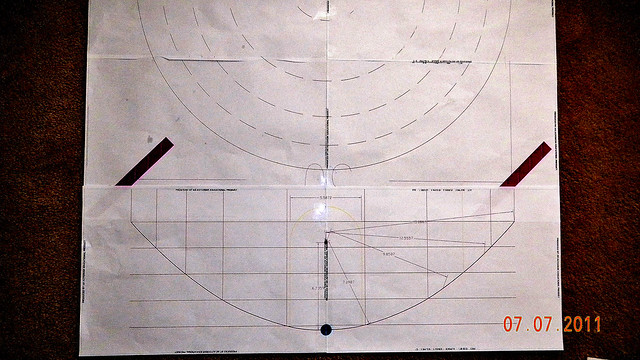

I jumped ahead and am about half way finished building the 30 Inch "NightHawk".

The 30" reflector mold is one of the best optically, I've ever made; and I did it in two days. The fiber-glassing should take one more day. I expect it to make the best beam.

I did this before I did any work on the SportLight or Mini LightSward, because key components ended up in Vegas when the Kia broke down. I hope to get everything back home when the car is fixed and I fly back to Vegas. :naughty:

I'll post some photos I've taken this week, during next couple days.

I jumped ahead and am about half way finished building the 30 Inch "NightHawk".

The 30" reflector mold is one of the best optically, I've ever made; and I did it in two days. The fiber-glassing should take one more day. I expect it to make the best beam.

I did this before I did any work on the SportLight or Mini LightSward, because key components ended up in Vegas when the Kia broke down. I hope to get everything back home when the car is fixed and I fly back to Vegas. :naughty:

I'll post some photos I've taken this week, during next couple days.

Last edited:

I hope some day to move away from the Chrome Tape, but it is inexpensive, fast and easy to use, with reasonable performance. I am looking at other options, but still don't really have the $$$ to make the change to 'Mirroring' yet...though on the upcoming "Light Sport" I may be in a better position to.

I hope some day to move away from the Chrome Tape, but it is inexpensive, fast and easy to use, with reasonable performance. I am looking at other options, but still don't really have the $$$ to make the change to 'Mirroring' yet...though on the upcoming "Light Sport" I may be in a better position to.