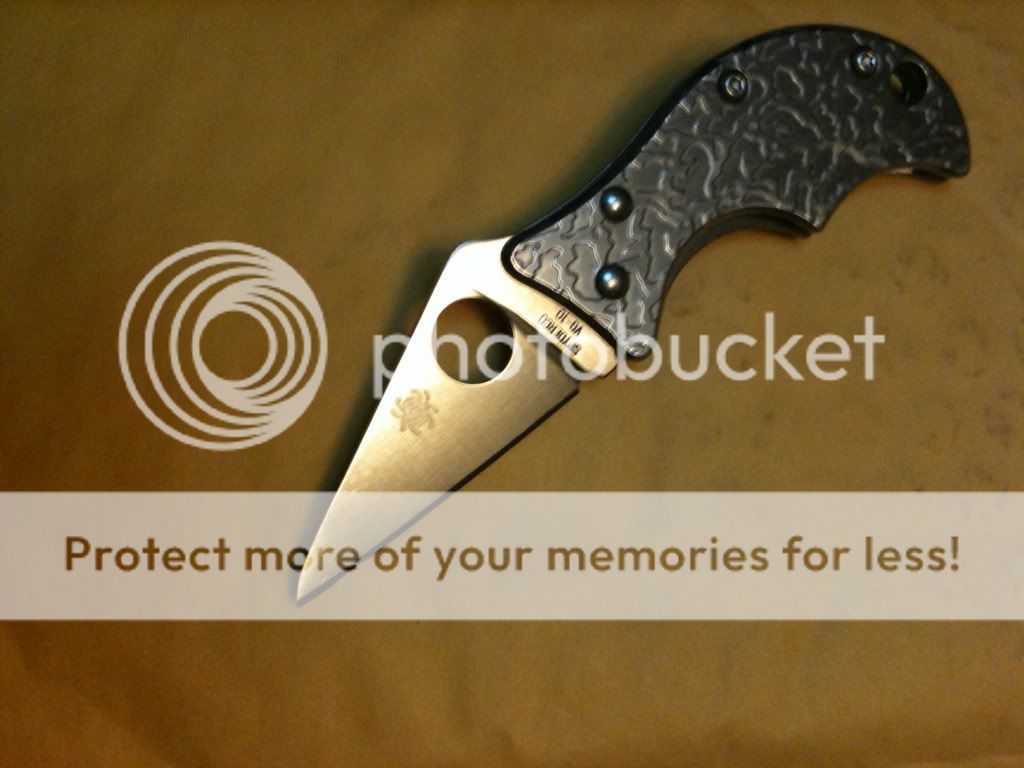

Best methods for repairing damaged blades? IE a knick in the cutting edge or a broken tip using it how it wasn't meant to be used? Different methods for different steels? IE 440, D2 Tool Steel, S30V, VG-10 etc?

Just file, polish and sharpen? If so, will a dremel type tool, or grinder heat the steel enough to affect the steel?

Just file, polish and sharpen? If so, will a dremel type tool, or grinder heat the steel enough to affect the steel?