wquiles

Flashaholic

Several years ago I modded this WoodRiver LED Dual Power Shop Light (Item #149727, available from Woodcraft for $33) by using a severely under-driven P7 LED (200mA). But that light has not been "enough", and I knew that with a plastic head I was limited to how much current I could feed the LED.

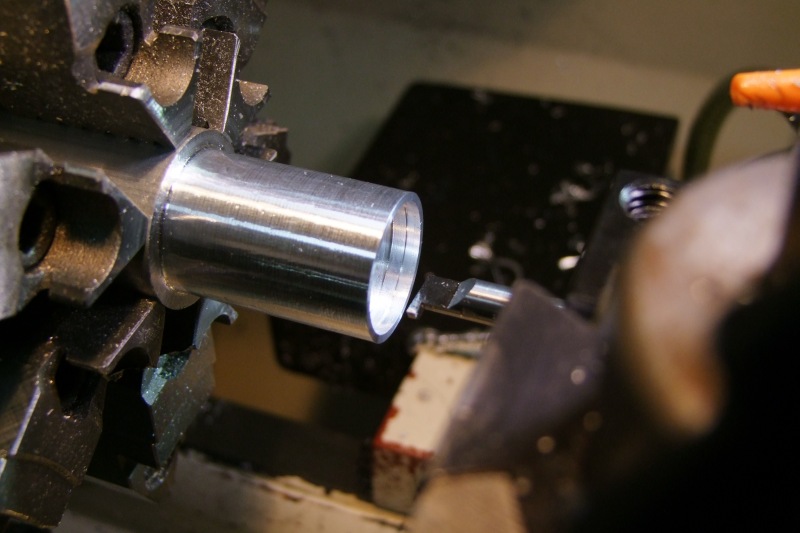

So I decided to make my own metal head for these lamps so that I can get more use of them. I started from a solid piece of Al:

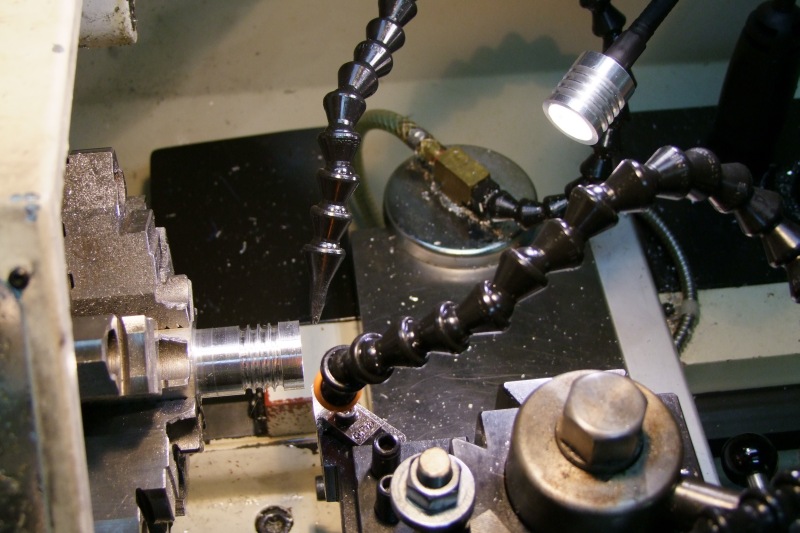

I added some cooling grooves:

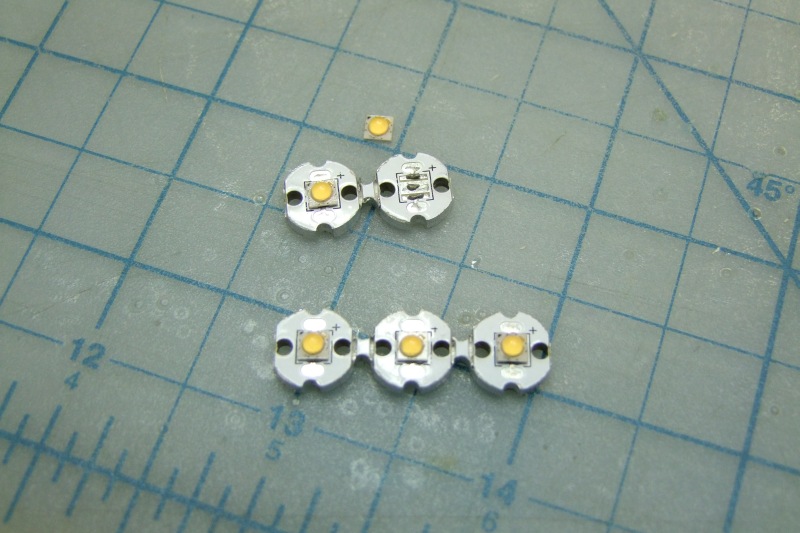

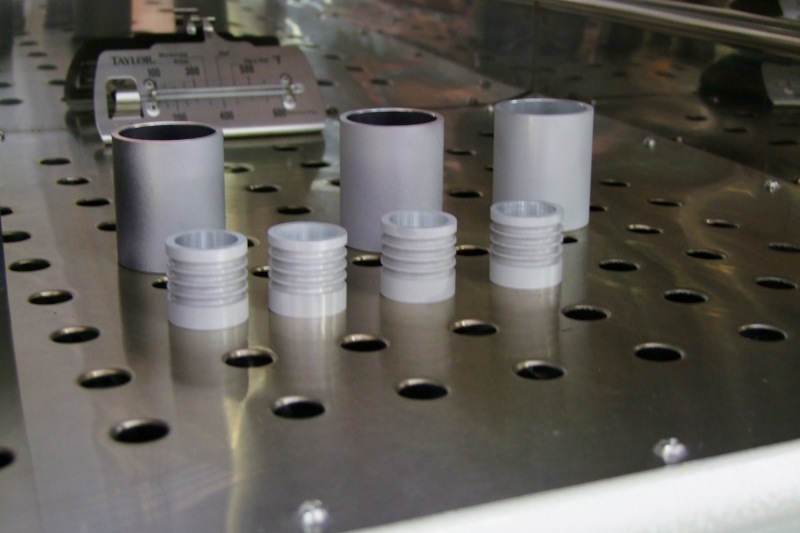

And using the Nichia 219's I made two prototypes:

I am using a frosted narrow and a frosted wide 20mm lens - how do they work?

With their flexible neck I can get the light where I need it, but this time I get plenty, beautiful, 4500K 92CRI light:

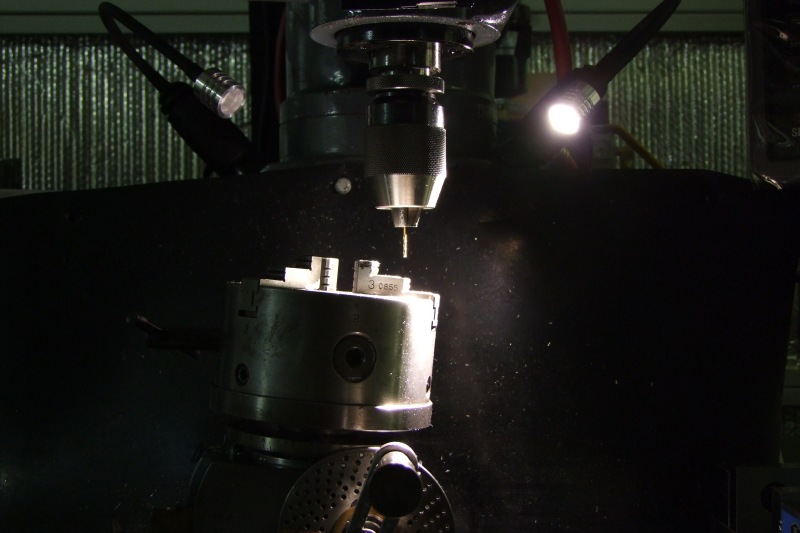

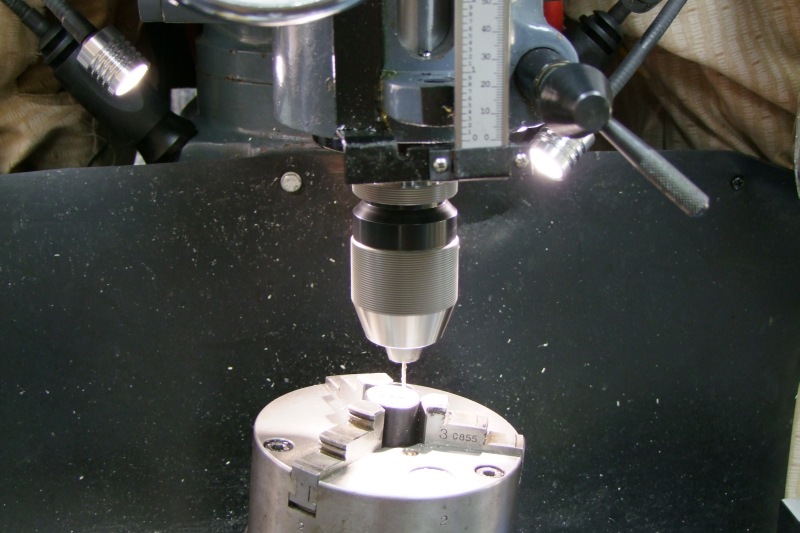

Here I am using one of them to cut more of the heads:

Since these work so well, I made some more for me, and a few more just in case:

I took 4x of them, sand blasted them, and then coated them with Moly Resin semi-gloss back:

Drill holes for LED wires:

And they are all done, ready for assembly:

I have been using these for the last two days, and they are working great. The surface temp (via IR temp measurement) hovers between 100-110F, with an ambient temp of about 80F. So they are definitely warm to the touch, but not hot enough to burn you when re-adjusting their aim. As a point of comparison, my Electrix 50 watt incandescent gets to about 135F with the same ambient temp - you can't keep your hand on that one for long!

By the way, although I used the Nichia 219's here, I did build one LED Shop Lamp using the Cree XP-G Warm White (the Cree has a more throwy beam although both have the same narrow frosted optics). The exposure is stepped down (these are fairly bright!). Here you can see them side-by-side: the one that looks "white" is the Nichia:

If there is enough interest I can start a sales thread for the extra pieces I made, which would make this into a neat and useful DIY project (steps in post #2), no lathe/mill required

Will

So I decided to make my own metal head for these lamps so that I can get more use of them. I started from a solid piece of Al:

I added some cooling grooves:

And using the Nichia 219's I made two prototypes:

I am using a frosted narrow and a frosted wide 20mm lens - how do they work?

With their flexible neck I can get the light where I need it, but this time I get plenty, beautiful, 4500K 92CRI light:

Here I am using one of them to cut more of the heads:

Since these work so well, I made some more for me, and a few more just in case:

I took 4x of them, sand blasted them, and then coated them with Moly Resin semi-gloss back:

Drill holes for LED wires:

And they are all done, ready for assembly:

I have been using these for the last two days, and they are working great. The surface temp (via IR temp measurement) hovers between 100-110F, with an ambient temp of about 80F. So they are definitely warm to the touch, but not hot enough to burn you when re-adjusting their aim. As a point of comparison, my Electrix 50 watt incandescent gets to about 135F with the same ambient temp - you can't keep your hand on that one for long!

By the way, although I used the Nichia 219's here, I did build one LED Shop Lamp using the Cree XP-G Warm White (the Cree has a more throwy beam although both have the same narrow frosted optics). The exposure is stepped down (these are fairly bright!). Here you can see them side-by-side: the one that looks "white" is the Nichia:

If there is enough interest I can start a sales thread for the extra pieces I made, which would make this into a neat and useful DIY project (steps in post #2), no lathe/mill required

Will

Last edited: