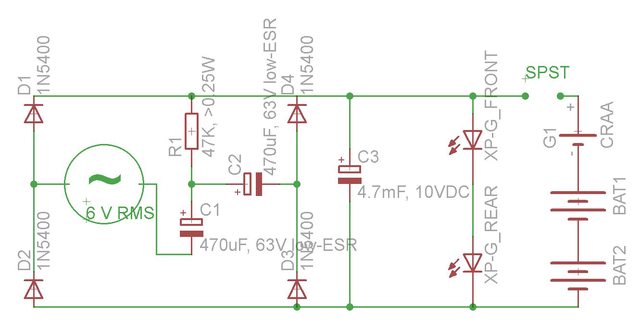

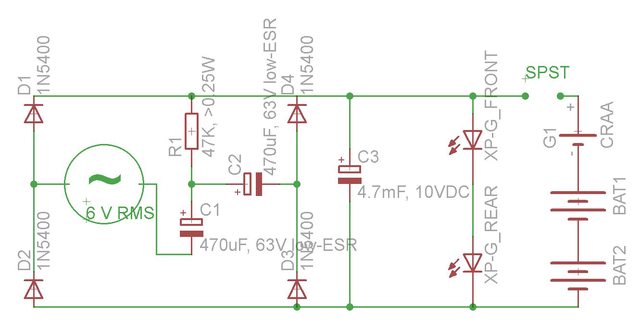

The reading of 0.6 makes sense, as that's about what I'd expect the forward voltage of a big silicon rectifier to be when conducting a small current. Not sure how it is getting 0.2v in the opposite direction. If there was something wired across the rectifier with 0.2v across it, then it should have been conducting when you measured in the opposite direction, producing a 0.2v reading both ways.

The only thing I can think of is that the electrolytic caps might be damaged and shorted. This might have happened if the LEDs weren't wired up as a load and the dynamo was spun at high speed.

You could have damaged the parts from poor soldering technique. If you are keeping the soldering iron on the joint more than a second or so, you are doing something wrong. The exception would be large conductors, like 16 ga wire. It does take longer to heat that stuff up.

About the only way to be sure is to start unsoldering one side of each component you want to check. You might have killed and shorted the LEDs, perhaps? Shoot... it could be anything!

Steve K.