Aepoc

Enlightened

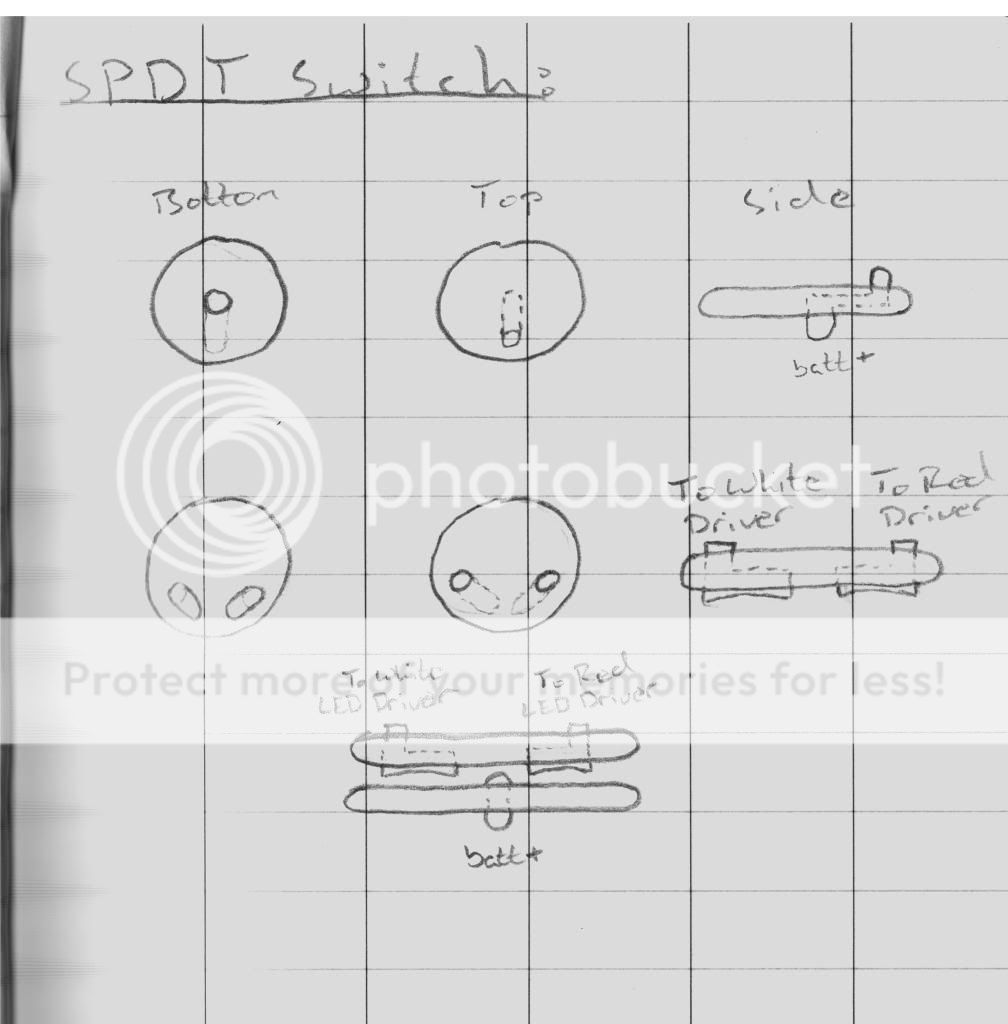

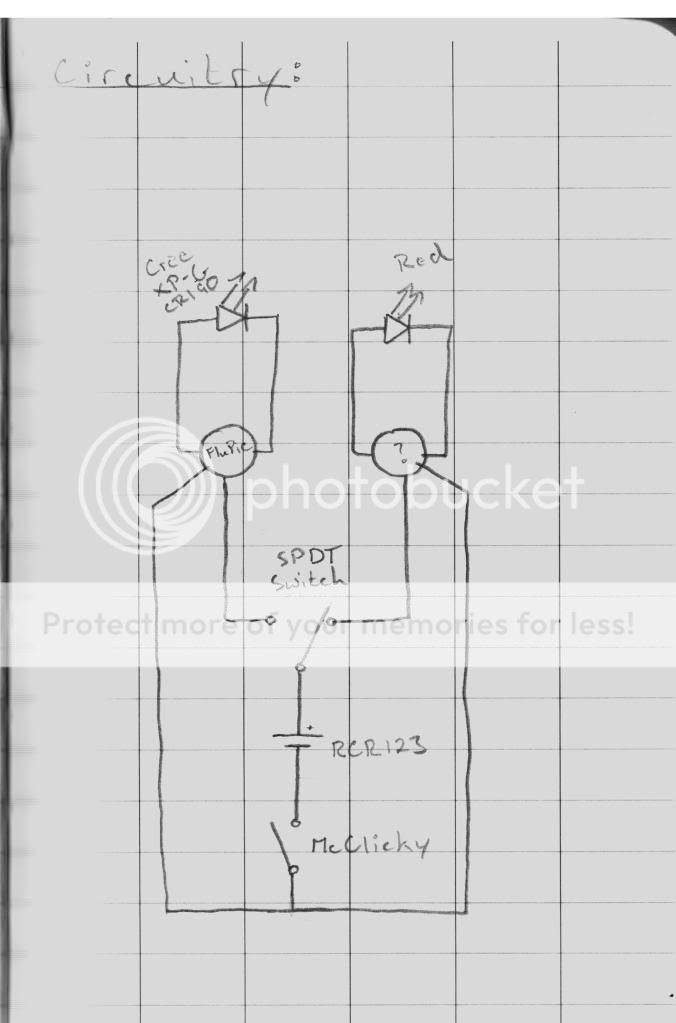

Has anyone out there made their own rotary switch/selector for a custom light? I'm building an EDC with both white and red LEDs and I am trying to figure out how I'm going to switch between the two colors... I will be using a McClicky to turn the light on and off, so I'm looking to make an SPDT (Single Output Double Throw) rotary style switch. I would like to make it so that I can turn the head a quarter turn or so, to switch between the red and white. I could use a store bought switch, but I'm worried about water resistance as all the switches I've seen (toggle and rocker style) would require creating another hole in the body... I'm thinking of building a swich that will be located between the posative cell terminal, and the two circuit boards that I will be using (one for each LED).

I have a few ideas thus far, but I'm having trouble locating parts to build my own switch. I have no idea where to look for blank circuit board material, prefferably circles ~1" in diameter. I'm also not sure what to use to carry the current through the switch. I have some copper and a dremel tool, but it would be nice if I could find some thin metal strands similar to what is used in a mag switch...

I have considered retrofitting an existing rotary switch, but I can't really find anything that would suit my needs.

I hope to get sketches up soon to help visualize what I am thinking. I would greatly appreciate any input on the design, and I am in despirate need of finding any parts...

Thanks in anvance!

I have a few ideas thus far, but I'm having trouble locating parts to build my own switch. I have no idea where to look for blank circuit board material, prefferably circles ~1" in diameter. I'm also not sure what to use to carry the current through the switch. I have some copper and a dremel tool, but it would be nice if I could find some thin metal strands similar to what is used in a mag switch...

I have considered retrofitting an existing rotary switch, but I can't really find anything that would suit my needs.

I hope to get sketches up soon to help visualize what I am thinking. I would greatly appreciate any input on the design, and I am in despirate need of finding any parts...

Thanks in anvance!