hi cpfers

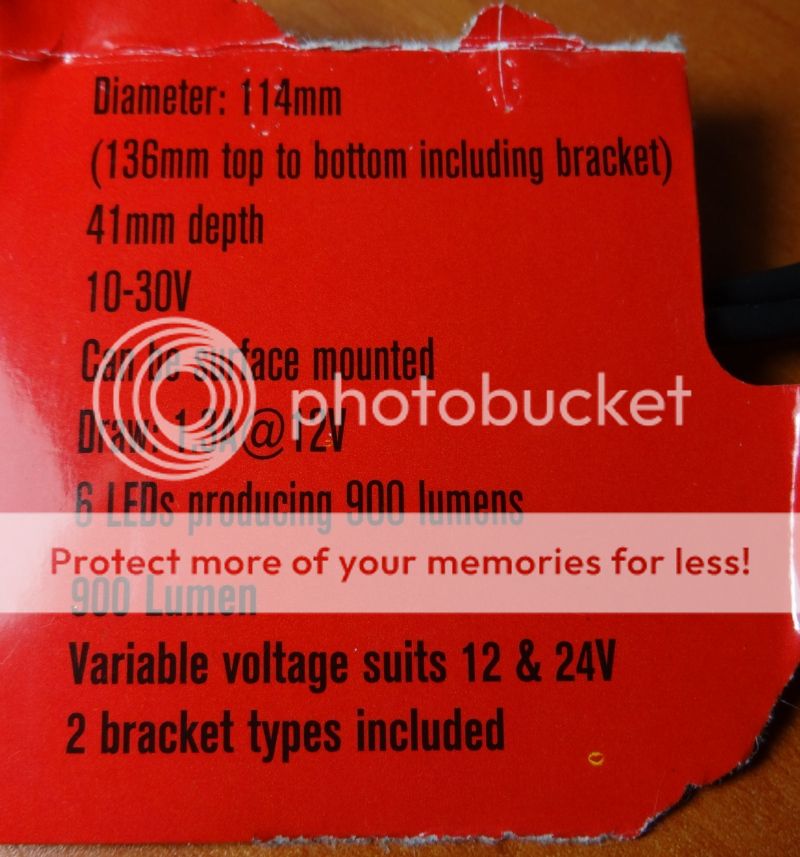

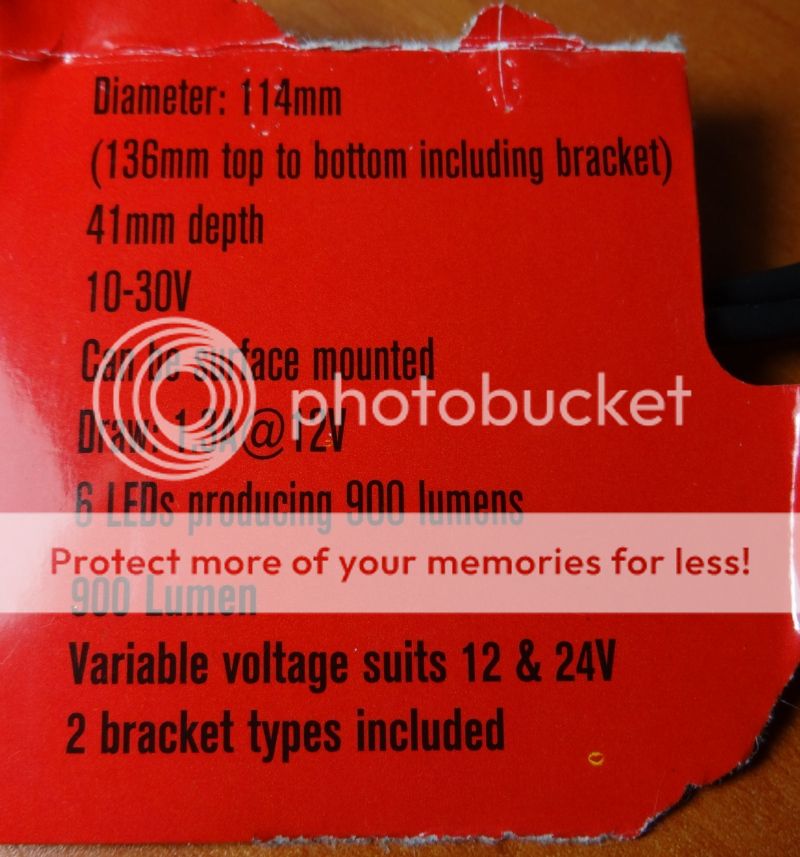

i picked up this 6x LED work light from a local shop.

it is rated for 1.3amp at 12v, and i have measure this to be accurate with a meter.

it appears to be preforming as specified on the label.

BUT, after 30mins hooked up to a 12v lead battery the unit is hot to touch. enough to hold it for 10secs without pain. this i am ok with.

but after 1 hour, it is too hot to touch, this i am NOT ok with this. light output appears normal.

unfortunately the unit is glued and can not be disassembled without great effort.

but looking through the lens i can see that there is a driver on the board where the emitters are seated. i am not surprised since the unit says 10-30volts which suggests regulation.

my intention for this light was to be on a garage hooked into a 12v solar system.

but the heat issue gives me concern that it will not last long, or worse become a hazard.

my questions;

1. is this unit too hot or is this normal for this type of worklight? can it handle this heat for 6 hours daily?

2. because i can see a driver inside already, i assume this means i can not PWM regulate its supply without sending the built-in driver nuts

3. am i wiring this correctly by hooking to straight to 12v (considering its regulated internally)?

pre-thanks!

i picked up this 6x LED work light from a local shop.

it is rated for 1.3amp at 12v, and i have measure this to be accurate with a meter.

it appears to be preforming as specified on the label.

BUT, after 30mins hooked up to a 12v lead battery the unit is hot to touch. enough to hold it for 10secs without pain. this i am ok with.

but after 1 hour, it is too hot to touch, this i am NOT ok with this. light output appears normal.

unfortunately the unit is glued and can not be disassembled without great effort.

but looking through the lens i can see that there is a driver on the board where the emitters are seated. i am not surprised since the unit says 10-30volts which suggests regulation.

my intention for this light was to be on a garage hooked into a 12v solar system.

but the heat issue gives me concern that it will not last long, or worse become a hazard.

my questions;

1. is this unit too hot or is this normal for this type of worklight? can it handle this heat for 6 hours daily?

2. because i can see a driver inside already, i assume this means i can not PWM regulate its supply without sending the built-in driver nuts

3. am i wiring this correctly by hooking to straight to 12v (considering its regulated internally)?

pre-thanks!

Last edited: