Julian Holtz

Enlightened

Hi!

In the meantime, I made my desklamps some more sophisticated.

Old thread here:

http://www.candlepowerforums.com/vb...with-awesome-brightness&p=3945157#post3945157

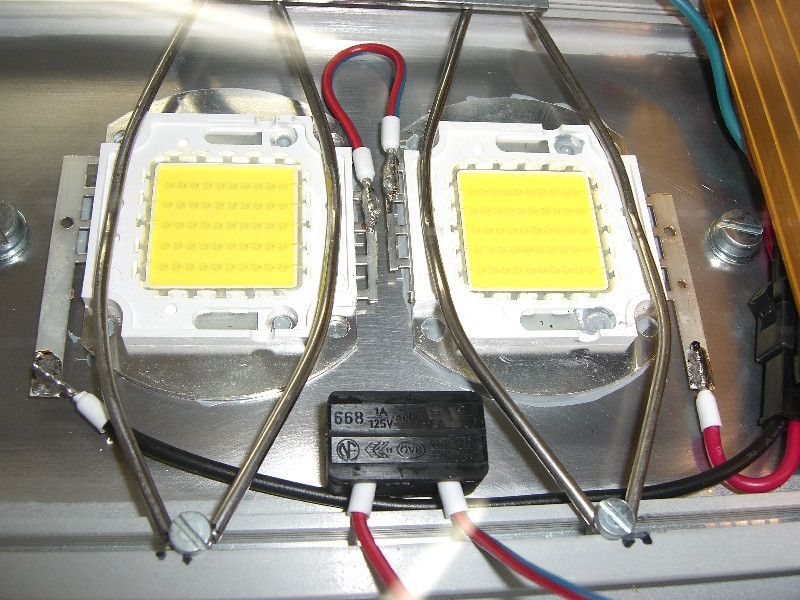

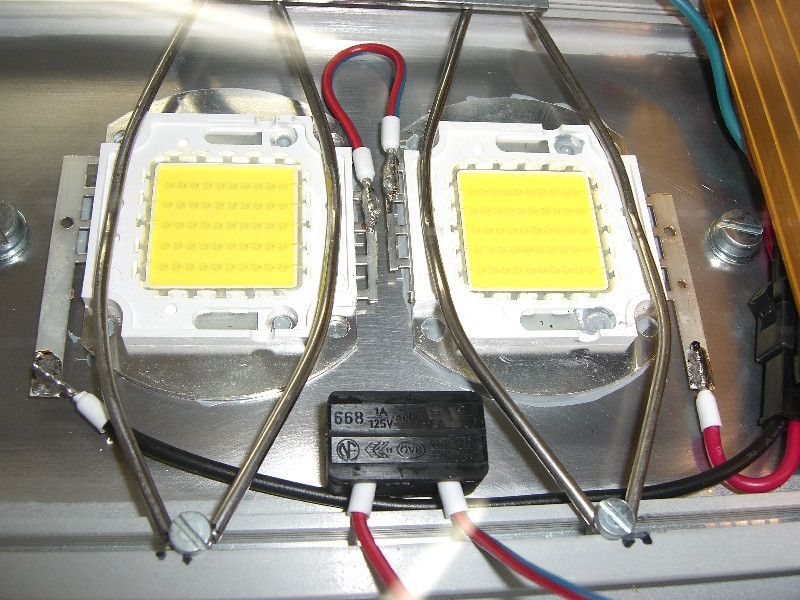

I decided to use these 50W LEDs instead of the LED strips.

http://www.wayjun.com/index.php?main_page=product_info&products_id=856

I chose the cold white version, which works out excellent as a work light.

I used the same driver as before, but now with a relais, as the current pulse at the beginning always burned out my switches.

I used Arctic cooling MX2 thermal paste. The LEDs are fixed by stainless steel bicycle spokes which are bent in a way that they constantly press the LEDs down. The surface of the aluminium was smoothed with 1000grit paper and slightly polished after that.

Before:

After:

Photo album:

http://imgur.com/a/lPyAo#2

http://imgur.com/a/voKaM#1

I cut a class panel to sit in the place where the aluminium sheet for the LED strips was located before.

I really like this mod much better! The light is brighter again, the lamp head provides good heatsinking, and these LEDs have a higher CRI.

In the meantime, I made my desklamps some more sophisticated.

Old thread here:

http://www.candlepowerforums.com/vb...with-awesome-brightness&p=3945157#post3945157

I decided to use these 50W LEDs instead of the LED strips.

http://www.wayjun.com/index.php?main_page=product_info&products_id=856

I chose the cold white version, which works out excellent as a work light.

I used the same driver as before, but now with a relais, as the current pulse at the beginning always burned out my switches.

I used Arctic cooling MX2 thermal paste. The LEDs are fixed by stainless steel bicycle spokes which are bent in a way that they constantly press the LEDs down. The surface of the aluminium was smoothed with 1000grit paper and slightly polished after that.

Before:

After:

Photo album:

http://imgur.com/a/lPyAo#2

http://imgur.com/a/voKaM#1

I cut a class panel to sit in the place where the aluminium sheet for the LED strips was located before.

I really like this mod much better! The light is brighter again, the lamp head provides good heatsinking, and these LEDs have a higher CRI.

Last edited: