Your responses are very encouraging. I think what I am going to do is put the 2 cell version up, as is, on kickstarter and if things go well, I will use the money I raise to produce the prototypes for my 4 cell version that will add different charge rates, a case, buttons and a color LCD.

Power Me Up, to answer your questions, the discharge rate is set in this version to average about a 5 hour discharge time for most AA batteries (it discharges into a 3.9 ohm resistor). This was chosen because mAh ratings are supposed to be calculated based on a load that will drain a battery in 5 hours. The problem is without knowing the actual capacity of a battery beforehand you can't calculate that load. So a 3.9 ohm resistive load turned out to be a nice average compromise. I did however make sure to use PWM pins for the N-channel fet's that control this load, so that if a different resister was used (which in an earlier version I used a 1.8 ohm) then you could use PWM to vary the discharge rate.

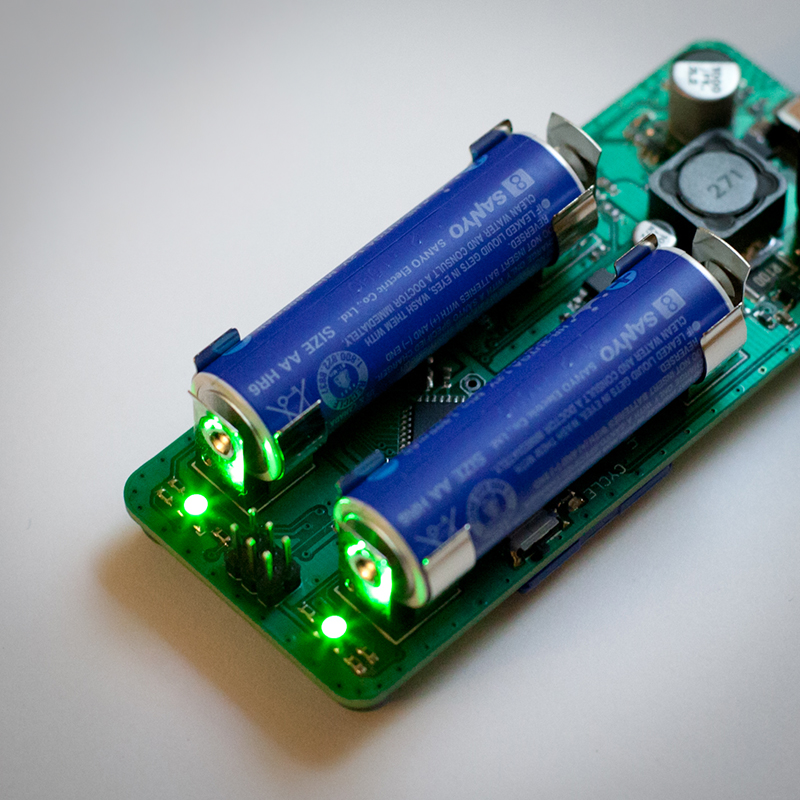

Charge Rate for this one is set at a pulsed 800mA rate. At 50% it averages to a 400mA rate. However this was more so that it could still use USB and not surpass drawing 500mA. I have a 1 Amp USB power supply and in software did test up to a 1.2Amp charge rate. Anything more then this and the inductor starts to get hot.

Accuracy right now is down to a change of 1.8mV minimum. When charging, because of the extra noise combined with filtering and averaging I actually get better than that (if you want to learn more as to why, you can look on the internet or ask me in a message).

For temperature I can detect a change of .18 degree C. I was using a different temperature sensor that gave me more sensitivity with 15mV/degree C, but saved almost a dollar per sensor by going with one that is only 10mV/degree C. It dropped my sensitivity... but not much : )

Current is accurate to within at least 1.8mA (notice a pattern? it's the 1.8V ref combined with a 10bit ADC) again though, because I only take current measurements during charging, I actually tend to get better than that.

As far as software, I have feelings both ways about making the code open source. I have spent hundreds of hours testing my code to make sure it is as robust as I can make it. I have also cycled countless batteries for the same reason. I have no problems with making it open source, so long as no one blamed me if they messed up and ruined something.

Going along with above, if I made the software open source, I would also change things so that you could reprogram and communicate with a PC through the USB.