Therrin

Newly Enlightened

- Joined

- Jun 25, 2010

- Messages

- 89

So my original machinist developed sudden brain cancer and passed away, and was also a father-figure to me, so that was kinda rough.

Then I got a new job and ended up working all over the country at different sites, then that job died off after the sites were finished and I've been out of work. In the meantime I moved from SoCal to Northern Illinois. Life just seems to have it's own plans sometimes.

But I'm back at it!

And I've secured a new machinist for prototyping, and have been logging hours on solidworks again.

I wanted to share what I'm working with so far. It's still in the R&D stage, so I'd really appreciate any comments, advice, suggestions, or questions.

It's easy to make something that *I* find useful, it's a bit more difficult to make something that I'd like other people to be happy with as well.

This was my original design:

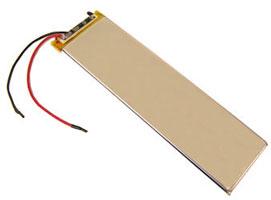

In the interests of decreasing bulk and weight-on-the-forehead, and allowing for better thermal exchange, I've gone a different way...

I'm looking at doing either an in-line switch (for helmet mounted it'd end up in the middle of the side likely), or a battery case mounted switch. But I'm also still playing with the idea of putting the switch(es) ON the lightbody itself. What are your thoughts on this subject?

Here are some pics of where I'm at right now... (no o-ring grooves or threads shown atm)

Right now I've got it set up so the head pieces are compatible with the SolarForce platform, but I'm looking at perhaps going a different direction for better waterproofing and fewer parts. Thoughts? Any overwhelming benefits seen to having compatible parts with another manufacturer?

The cable port on the side will likely be a 90*elbow cable gland. The current piece in the picture is just for show.

The smaller holes above the cable port are the threaded holes for the mounting bracket.

Also thinking of revising the heat-fins on the head pieces. Perhaps fewer, a little thicker, with perpendicular cut-outs I'm trying to accommodate future LED technology and high heat levels to protect the dropins.

My goal is for you to be able to use common P60 dropins; with simple, user-friendly screw on modifications to change one over to a "flood" type, and the ability to run one or BOTH of them at the same time. Spot/Flood/Spot&Flood, in whatever modes you choose based on whatever dropins YOU want to use. With a single switch design they SHOULD be matched dropins, but with a double switch, you could operate each one independently based on your needs.

Toying with making the cable entrance go through to both sides, with a plug in the unused side to allow the wires to be run off either side, based on the user's needs. Adds one more spot to o-ring and adequately waterproof. Good? Bad?

What do you think?

Then I got a new job and ended up working all over the country at different sites, then that job died off after the sites were finished and I've been out of work. In the meantime I moved from SoCal to Northern Illinois. Life just seems to have it's own plans sometimes.

But I'm back at it!

And I've secured a new machinist for prototyping, and have been logging hours on solidworks again.

I wanted to share what I'm working with so far. It's still in the R&D stage, so I'd really appreciate any comments, advice, suggestions, or questions.

It's easy to make something that *I* find useful, it's a bit more difficult to make something that I'd like other people to be happy with as well.

This was my original design:

In the interests of decreasing bulk and weight-on-the-forehead, and allowing for better thermal exchange, I've gone a different way...

I'm looking at doing either an in-line switch (for helmet mounted it'd end up in the middle of the side likely), or a battery case mounted switch. But I'm also still playing with the idea of putting the switch(es) ON the lightbody itself. What are your thoughts on this subject?

Here are some pics of where I'm at right now... (no o-ring grooves or threads shown atm)

Right now I've got it set up so the head pieces are compatible with the SolarForce platform, but I'm looking at perhaps going a different direction for better waterproofing and fewer parts. Thoughts? Any overwhelming benefits seen to having compatible parts with another manufacturer?

The cable port on the side will likely be a 90*elbow cable gland. The current piece in the picture is just for show.

The smaller holes above the cable port are the threaded holes for the mounting bracket.

Also thinking of revising the heat-fins on the head pieces. Perhaps fewer, a little thicker, with perpendicular cut-outs I'm trying to accommodate future LED technology and high heat levels to protect the dropins.

My goal is for you to be able to use common P60 dropins; with simple, user-friendly screw on modifications to change one over to a "flood" type, and the ability to run one or BOTH of them at the same time. Spot/Flood/Spot&Flood, in whatever modes you choose based on whatever dropins YOU want to use. With a single switch design they SHOULD be matched dropins, but with a double switch, you could operate each one independently based on your needs.

Toying with making the cable entrance go through to both sides, with a plug in the unused side to allow the wires to be run off either side, based on the user's needs. Adds one more spot to o-ring and adequately waterproof. Good? Bad?

What do you think?

Last edited: