jdp298

Newly Enlightened

Conceptually, I know exactly what I want to do, but am having trouble designing it/building.

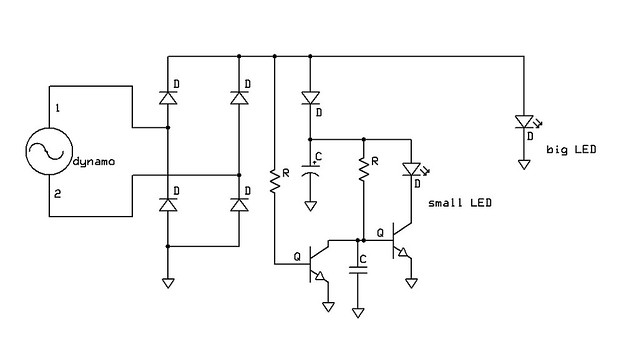

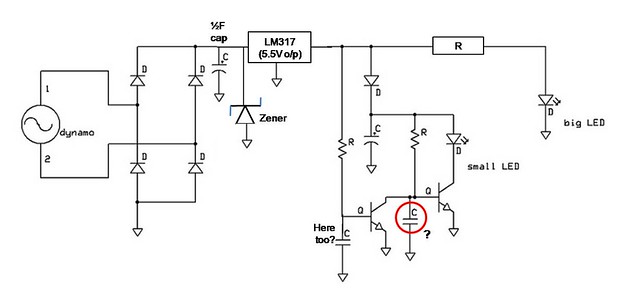

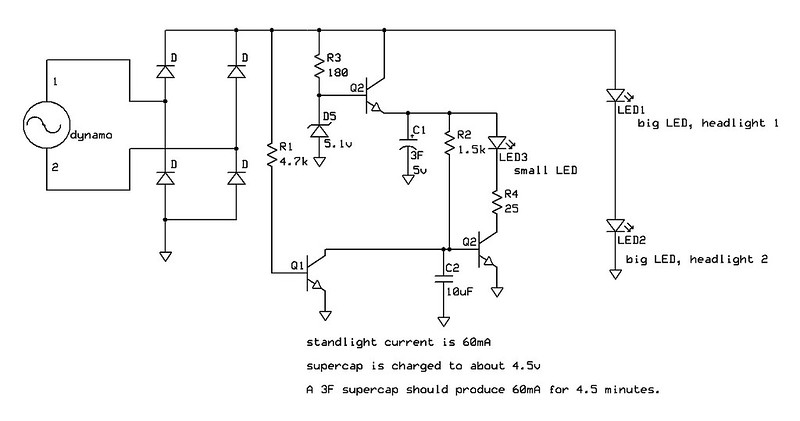

As per some of the fancy German dynamo headlights, I want to switch out the big LED when the wheel stops turning, and switch over to a pair of lower power white ones. With a relay, this would be v.simple, but I don't want to spend the power on driving a relay coil whenever I'm moving.

Turning the big one off and on with an npn transistor makes sense, and if I only do that then I can run the pair of small ones all the time. Thing is, there's no point in that, they'd be lost beside the big one and eating power (however small). I've been toying with the idea of a pnp held shut straight out of the rectifier, and then when that goes quiet, the power in the supercap can pass to the small ones. I'm sure this is achievable without anything with more than 3 pins but I can't nail it down.

Any thoughts?

As per some of the fancy German dynamo headlights, I want to switch out the big LED when the wheel stops turning, and switch over to a pair of lower power white ones. With a relay, this would be v.simple, but I don't want to spend the power on driving a relay coil whenever I'm moving.

Turning the big one off and on with an npn transistor makes sense, and if I only do that then I can run the pair of small ones all the time. Thing is, there's no point in that, they'd be lost beside the big one and eating power (however small). I've been toying with the idea of a pnp held shut straight out of the rectifier, and then when that goes quiet, the power in the supercap can pass to the small ones. I'm sure this is achievable without anything with more than 3 pins but I can't nail it down.

Any thoughts?