Hello,

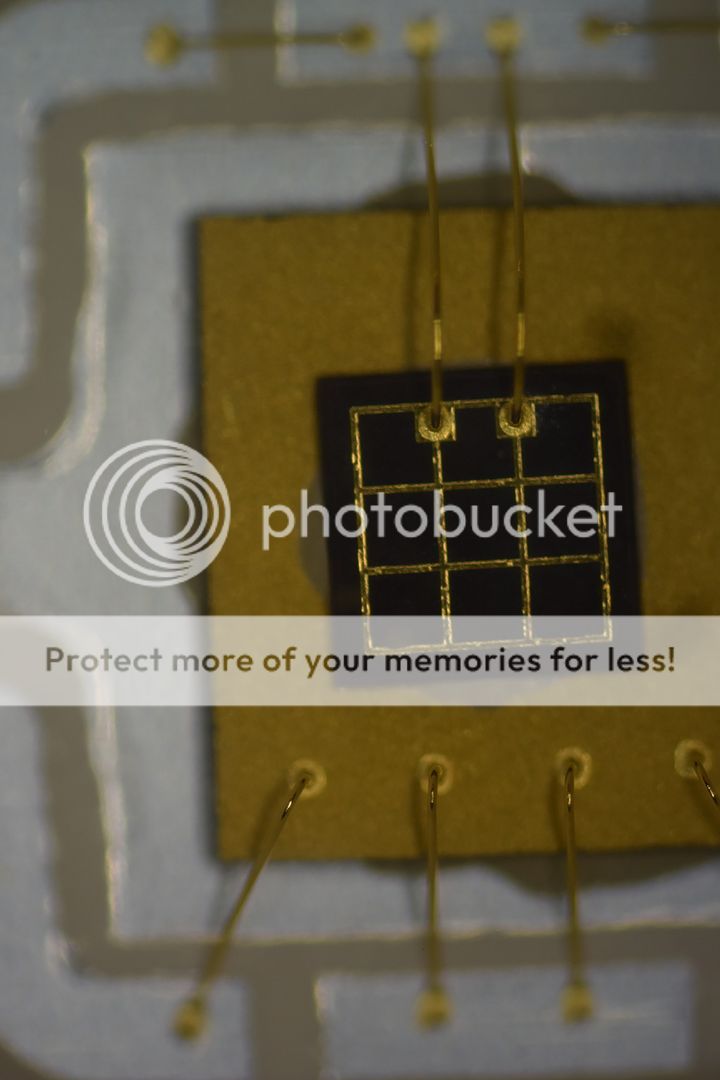

I just came across these 10 leds still in the sealed foil. I forgot that I ever had them. I was hung up by not having the boards, and the company was not so interested in selling small orders. I bought them as a sample order. Here is a pdf file of the exact led board dimensions http://tech-led.com/data/SMB680-1100-I.pdf Does anyone have boards for these leds or a link to someone who might supply them? I might also be interested in a mounting service. I have mounted some very small leds but my eyes are not as sharp and I had access to magnifying viewers. I do like the challenge though of doing it myself.

Thanks for any help

Inkidu

I just came across these 10 leds still in the sealed foil. I forgot that I ever had them. I was hung up by not having the boards, and the company was not so interested in selling small orders. I bought them as a sample order. Here is a pdf file of the exact led board dimensions http://tech-led.com/data/SMB680-1100-I.pdf Does anyone have boards for these leds or a link to someone who might supply them? I might also be interested in a mounting service. I have mounted some very small leds but my eyes are not as sharp and I had access to magnifying viewers. I do like the challenge though of doing it myself.

Thanks for any help

Inkidu