You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

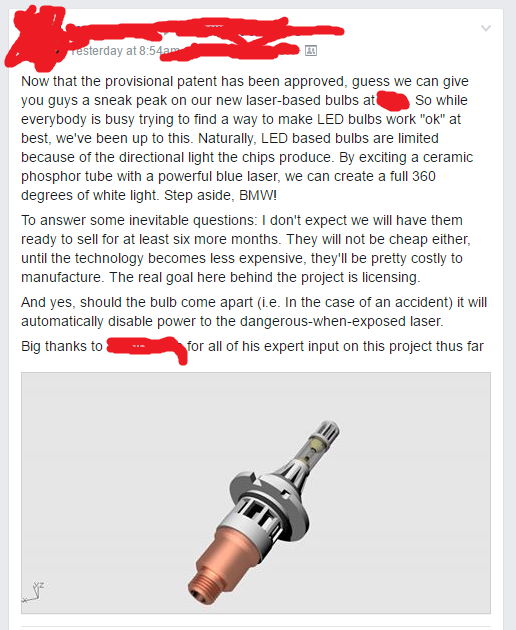

Merry Christmas, laser Plug n Play has been invented.

- Thread starter 64.5vette

- Start date

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

Oh, heck, yeah! The aftermarket is where it's at, bro! Step aside, Audi, you slow laggard...we don't gotta wait no more for this dope aftermarket imitation, I mean version, of Audi's proposed laser rear fog lamp. Check it out, you can hook it to the license plate light circuit just like the video guy says in the caption! And We don't gotta buy no expensive Audi, either, we can get it right on Amazon! I'm gonna get three of 'em for my hot Chevy Cavalier Z24, then it'll be three times as good as an Audi! Haters gonna hate!

Alaric Darconville

Flashlight Enthusiast

h8ers gotta H8, maing!

Everyone KNOES it's because Audi sponsirs us and that's why we don't let peeps sell their stuff which is actally bettir then what Audi makes! It's a conspirisy!!!!!

-------------

Ouch, that is painful to even TYPE.

"Amazon: When DealExtreme just doesn't have enough unsafe automotive lighting for you"

And a "full 360 degrees of white light"? Wow, a filament bulb produces nearly 4 pi steradians of light. Guess emitting light in only two dimensions instead of three is the latest technological advancement-- in Elbonia.

Everyone KNOES it's because Audi sponsirs us and that's why we don't let peeps sell their stuff which is actally bettir then what Audi makes! It's a conspirisy!!!!!

-------------

Ouch, that is painful to even TYPE.

"Amazon: When DealExtreme just doesn't have enough unsafe automotive lighting for you"

And a "full 360 degrees of white light"? Wow, a filament bulb produces nearly 4 pi steradians of light. Guess emitting light in only two dimensions instead of three is the latest technological advancement-- in Elbonia.

Last edited:

Alaric/Virgil,

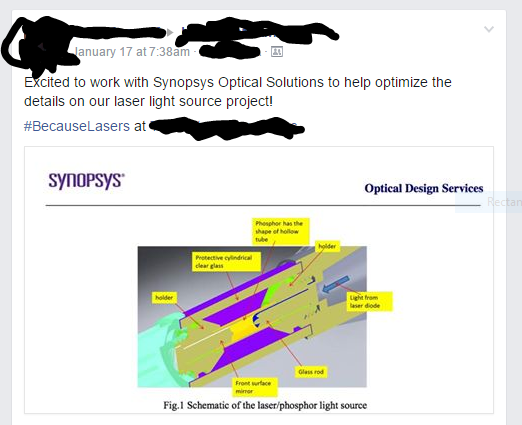

Sorry guys, but you are not right this time .... nor are the "inventors" alone in this field ... or crazy, though I wonder if they have solved the practical aspects for a headlight bulb replacement ... including whether there is going to be an adequate market.

A partially hollow phosphor tube pumped with a laser has a better chance of simulating the size and emission pattern of an incandescent coil than anything that has been proposed.

Sorry guys, but you are not right this time .... nor are the "inventors" alone in this field ... or crazy, though I wonder if they have solved the practical aspects for a headlight bulb replacement ... including whether there is going to be an adequate market.

A partially hollow phosphor tube pumped with a laser has a better chance of simulating the size and emission pattern of an incandescent coil than anything that has been proposed.

Last edited:

127.0.0.1

Flashlight Enthusiast

SemiMan

all good and whatnot, but unless the lamp assembly and housing is specifically designed for this laser bulb,

it is not a viable solution as a replacement lamp for any existing assemblies

all good and whatnot, but unless the lamp assembly and housing is specifically designed for this laser bulb,

it is not a viable solution as a replacement lamp for any existing assemblies

Sorry but you are wrong.

Similar to the LED bulbs that Philips has type approved in specific lamp assemblies, the same could be done with a bulb of this construction (likely models with a bulb shield). The technology has the potential to accurately simulate the size and emission pattern of a filament bulb. If you can do that, then certifying in specific lamp assemblies is not difficult.

Similar to the LED bulbs that Philips has type approved in specific lamp assemblies, the same could be done with a bulb of this construction (likely models with a bulb shield). The technology has the potential to accurately simulate the size and emission pattern of a filament bulb. If you can do that, then certifying in specific lamp assemblies is not difficult.

When I read 'they'll be pretty costly to manufacture. The real goal here behind the project is licensing', I interpreted that to mean 'it's gonna be really expensive to manufacture, but that's not our problem. We're just selling our idea - it's someone else's job to figure out how to produce it at a reasonable cost.'. But, maybe that's just the cynic in me.

Still, a good idea if it works and can be sold at a non cost-prohibitive price. I guess we'll see.

Still, a good idea if it works and can be sold at a non cost-prohibitive price. I guess we'll see.

Similar to the LED bulbs that Philips has type approved in specific lamp assemblies

No such LED bulb. None of Philips' LED retrofit bulbs are type-approved. The closest they come is publishing a small list of some vehicle models they've tested some of their brake/tail and backup light LED bulbs in and found them to produce a light distribution that meets the photometric requirements for the various functions. That's better than nothing, but it's a long way from a legitimate, legally adequate certification, and it has nothing at all to do with type-approval. Moreover, a vehicle's inclusion on that list doesn't necessarily mean what it looks like it means. There is at least one very popular vehicle on the list, for example, that shows "OK" for the stop and tail light functions with the Philips LED bulb, but using that bulb in that lamp effectively eliminates the vehicle's rear side marker lights. There's no mention of this on that list.

The technology has the potential to accurately simulate the size and emission pattern of a filament bulb. If you can do that, then certifying in specific lamp assemblies is not difficult.

...except that it's legally impossible. Regulations and laws could be changed to permit retrofits of different light sources of the nature of this proposed laser bulb, but it's never happened before and it's not likely to happen any time soon, for valid technical reasons.

The 3D rendering of the proposed laser bulb shows it to be a non-starter for retrofit purposes: look at that frame/board surrounding the phosphor tube. That's going to mean a light emission pattern that is, at the optical level, radically different than the one produced by a filament -- even if the phosphor tube is exactly the same size and shape and in exactly the same position, and emits exactly the same luminous flux. That kind of optical difference shoots an arrow right through the heart of any hope for such a light source being a drop-in retrofit for any/every application of a filament bulb of whatever type.

Furthermore, the 3D rendering clearly shows a P32d-2 base -- that's the one used on the D2S HID bulb. HID bulbs do not have a cylindrical light source, they have a crescent-shaped light source. The optics of HID headlamps are specifically prescribed for a crescent-shaped light source. Putting a cylindrical light source in will wreck the beam pattern in much the same way as putting a crescent-shaped light source wrecks the beam pattern of a headlamp with optics for a (cylindrical) filament light source.

If we step back far enough from reality, the concept isn't totally implausible. But that's only if we strip away a whole bunch of pesky technical, optical, and legal requirements that exist (and will keep on existing) in the real world.

Last edited:

Virgil,

My use of "type approved" was poor choice but to your point Philips has tested their bulb in assemblies and shown they meet the legal requirements for certain functions and there is no reason that the same could not be done with a design using this implementation method. If I am not mistaken, if you meet the requirements of the function in a given assembly, then the installation is legal. What you can't do is say carte-blanche it will work in any assembly without violating photometric requirements ..... though one could argue exactly that is done with the higher output bulbs. There is no guarantee they will not violate maximums, it is just known that practically that is not the case.

You are also making as big of leaps on optical performance of this structure as those that have posted this crude rendering.

I am not seeing a frame/board around the ceramic phosphor tube in the rendering. I am seeing structure below (as would an incandescent bulb) and structure above, again as could occur in a light shield in an incandescent bulb. That said, even with partial shielding, depending on the optical headlamp assembly in which it is placed, it could meet photometric requirements.

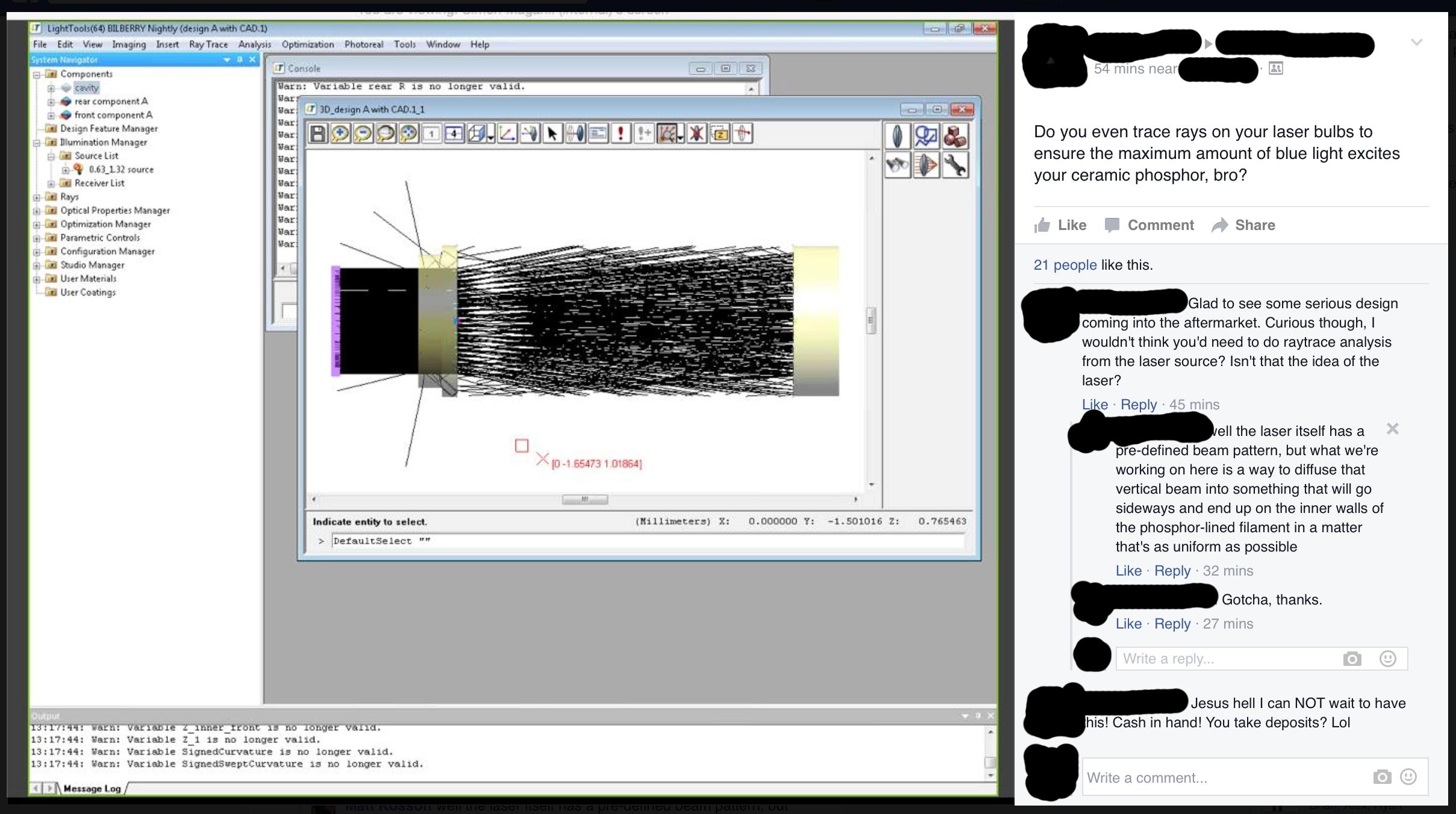

There are significant technical hurdles to bringing such a product to market, such as the basics of a pump diode of sufficient power/efficiency, and certainly the very non-trivial design of the inside of the phosphor cavity to achieve a near 360 degree radiation with adequate color consistency, but the basic concept is actually sound. To dismiss it out of hand without a discussion on the potential for success and to at least give the inventors (and others like them) their due for a creative and potential viable solution to a problem is not suitable.

My use of "type approved" was poor choice but to your point Philips has tested their bulb in assemblies and shown they meet the legal requirements for certain functions and there is no reason that the same could not be done with a design using this implementation method. If I am not mistaken, if you meet the requirements of the function in a given assembly, then the installation is legal. What you can't do is say carte-blanche it will work in any assembly without violating photometric requirements ..... though one could argue exactly that is done with the higher output bulbs. There is no guarantee they will not violate maximums, it is just known that practically that is not the case.

You are also making as big of leaps on optical performance of this structure as those that have posted this crude rendering.

I am not seeing a frame/board around the ceramic phosphor tube in the rendering. I am seeing structure below (as would an incandescent bulb) and structure above, again as could occur in a light shield in an incandescent bulb. That said, even with partial shielding, depending on the optical headlamp assembly in which it is placed, it could meet photometric requirements.

There are significant technical hurdles to bringing such a product to market, such as the basics of a pump diode of sufficient power/efficiency, and certainly the very non-trivial design of the inside of the phosphor cavity to achieve a near 360 degree radiation with adequate color consistency, but the basic concept is actually sound. To dismiss it out of hand without a discussion on the potential for success and to at least give the inventors (and others like them) their due for a creative and potential viable solution to a problem is not suitable.

Last edited by a moderator:

to your point Philips has tested their bulb in assemblies and shown they meet the legal requirements for certain functions

Certain functions. Not all of them in every lamp they've got on their list, which proves my "no" point, not your "yes". It means installing those bulbs in those applications counts as rendering mandatory equipment inoperative, which is illegal (if a regulated party does it) and really dumb (if anyone does it).

and there is no reason that the same could not be done with a design using this implementation method.

Well, anyone's welcome to do whatever tests and compile whatever lists they want, but none of them carry legal weight.

If I am not mistaken, if you meet the requirements of the function in a given assembly, then the installation is legal

You are mistaken.

What you can't do is say carte-blanche it will work in any assembly without violating photometric requirements

Which is the deal-breaker. The whole point of standardized light sources is their interchangeability. An HB4 bulb, any HB4 bulb built to the standardized specifications, works acceptably in any headlamp designed to accept an HB4 bulb. We don't have lists saying "OK, you can use this bulb in 1997-2003 Buick Century, 1999 Chevrolet Malibu, 1990-93 Honda Accord", etc.

Also, that's not what "carte blanche" means.

though one could argue exactly that is done with the higher output bulbs

Not based on any facts, one couldn't.

I am not seeing a frame/board around the ceramic phosphor tube in the rendering.

It's right there. Flat plate extending left and right from the tube.

the basic concept is actually sound

...as I said near the end of my post. Unfortunately, the significant problems with the concept in the only context it makes sense to consider it in (the real world) mean it is a non-starter, at least as presented.

Last edited:

Echo63

Flashlight Enthusiast

Let me see if i understand.

this laser "bulb" cant be used in a halogen assembly, because the specs that the manufacturer claims the headlamp assembly meets, specifies a bulb type and just because this has the right base and emitter position, it isnt compliant because it doesnt torture a bit of tungsten in a glass tube ?

Does that then mean that the only way this "bulb" will be ok for use is in an appropriately designed headlamp assembly (which could jist as easily be designed for LED, or HID, or Halogen instead)

this laser "bulb" cant be used in a halogen assembly, because the specs that the manufacturer claims the headlamp assembly meets, specifies a bulb type and just because this has the right base and emitter position, it isnt compliant because it doesnt torture a bit of tungsten in a glass tube ?

Does that then mean that the only way this "bulb" will be ok for use is in an appropriately designed headlamp assembly (which could jist as easily be designed for LED, or HID, or Halogen instead)

this laser "bulb" cant be used in a halogen assembly, because the specs that the manufacturer claims the headlamp assembly meets, specifies a bulb type and just because this has the right base and emitter position, it isnt compliant because it doesnt torture a bit of tungsten in a glass tube?

Legally, that's the case. Technically, the reasons are more numerous and complex. The main optical one is discussed above. There are others, too. Let's suppose we can wiggle our nose like Samantha Stevens on "Bewitched" (see here if you aren't familiar) and move this idea directly to the actual-product stage. Presto, we have a laser-and-phosphor-tube "bulb" designed to go in place of an HB4 (9006) halogen bulb.

It is an established principle of the governing laws and regulations that fundamentally different types of light source cannot be legal in headlamps even if they're designed to be physically and geometrically compatible, and that headlamps and bulbs be designed to prevent installation or acceptance of any but the intended bulb -- some of those prevention features are more robust than others, some are easily defeated, but that's beside the point. We have this light source that we have designed to put out exactly the same amount of light, its emitting surface is the same size and shape as the HB4 filament and it's positioned the same. But glowing phosphor tubes aren't the same as glowing filaments, and can't be made to be the same. The luminance distribution is different, for example. There are going to be fundamental differences in the output. Since 1986, there have been many thousands of different headlamps designed to use the HB4 bulb. What proportion of them do we have to test and get beam photometry results that are practically identical (or let's make it easier and say results that are legally acceptable) in order to declare this laser bulb a drop-in? If the answer isn't 100%, it's damn near, because there are real and serious liability issues involved.

Now let's assume we test (say) 2500 different HB4 headlamps, including a large number of all kinds of different optical technologies -- projectors, parabolic reflectors, compound-optic reflectors of all types, with bulb shields, without bulb shields, round, rectangular, large, small, VOL, VOR, the whole gamut -- and this laser bulb sailed through the beam tests each and every time, so even the most hardnosed NHTSA engineer had to admit that optically and photometrically, for all intents and purposes this thing is a drop-in. Then does the regulation change? No, because all those headlamps that stay free of snow and ice buildup in wintertime conditions with a halogen bulb now frost up quickly and badly when equipped with this new light source. Light comes out the front of the laser diode...and heat gets pulled off the back. The driver can't see any more when he needs his headlamps the most, which is a long way of saying the headlamps have been rendered inoperative, which is a direct and large violation of federal law in place for very good reasons.

And speaking of the back: take another look at that rendering of this laser bulb. Notice how much longer and more massive it is behind the seating plane than the bulb it replaces: about triple not counting whatever is obviously intended to screw onto what's shown here as the rearmost point of the bulb. No problem if we're putting it in a self-contained, sealed headlamp with a sturdy, robust bulb seat, in a large vehicle with ample space behind the headlamps. But many vehicles have almost no space behind the headlamps, and even if they did, that's not the only kind of headlamp out there, not by a long shot. There are also many headlamps that have reflectors and internal optics that are open to the elements unless the bulb access panels are firmly installed. The bulb access panels go behind the bulbs, and often there's not much clearance between the rear of the (intended) bulb and the access panel. Oops...guess we'll have to leave the bulb access panel off once we install this laser bulb. Now our headlamps quickly fill up with water and dirt and errant spiders. And what of the many headlamps that have bulb holders just adequate to hold a small, low-mass halogen bulb in position? Suddenly we're throwing a big lever against these bulb holders. The back of the bulb will sag downward (and jump up and down as we go over road bumps). Not only is our beam pattern shot to hell, not only is it bouncing around on the road, but now we've got another access path for water and dirt.

Shall I go on? (I can...I could talk about the reason why the Philips "here's a list of vehicles we tried these on and found OK results" strategy, while weakly arguable in the case of stop/reverse/tail/turn signal bulbs, is not even arguably valid for headlight lamps because of differences in how they're regulated...)

Does that then mean that the only way this "bulb" will be ok for use is in an appropriately designed headlamp assembly (which could jist as easily be designed for LED, or HID, or Halogen instead)

Yes. If the idea makes it to a commercial stage, it might be suitable for creating new light sources not intended for retrofitting in place of old light sources.

Last edited:

The manufacturer of the "replacement laser bulb" could test, as an assembly, the combination of the bulb and the headlight, for photometrics, corrosion, humidity, vibration, dust, spray, incursion, etc. The "replacement bulb" would not be tested for compliance per-se but the combination.

It would be difficult to form a legal argument that the installation of the new "headlight assembly" which passes all requisite SAE requirements is either unsafe or violates specific laws, especially since, to my knowledge, 108 /SAE does not call out specific manufacturing methods, only test methods and validation for the design ... and hence creation of the assembly by a trained/approved VAR could be acceptable. "User" installation may not be a viable path ... and no, I don't have a solution for the "new" marking of the completed headlight assembly.

I am surprised that Philips is advocating/marketing their XtremeVision LED fog bulbs in the U.S. without consideration to the vehicle they are being installed into but I have to expect their lawyers have spent considerable time to ensure they are not legally exposed which is likely backed up by extensive testing on the engineering side to show compliance .... perhaps not 100% compliance, but enough to make the lawyers happy.

That is a completely acceptable usage of the term "carte blanche" which means to do or say as you please.

There is no frame/board around the ceramic tube. The rendering is low resolution and is making the glass-envelope appear as such perhaps the way you are interpreting it.

I am not implying this is a simple problem to solve, but the only people who normally get rich from solving simple problems are criminals, lawyers and politicians.

Virgil, what is the SAE standard governing ice/snow buildup on headlights and the appropriate testing methods?

It would be difficult to form a legal argument that the installation of the new "headlight assembly" which passes all requisite SAE requirements is either unsafe or violates specific laws, especially since, to my knowledge, 108 /SAE does not call out specific manufacturing methods, only test methods and validation for the design ... and hence creation of the assembly by a trained/approved VAR could be acceptable. "User" installation may not be a viable path ... and no, I don't have a solution for the "new" marking of the completed headlight assembly.

I am surprised that Philips is advocating/marketing their XtremeVision LED fog bulbs in the U.S. without consideration to the vehicle they are being installed into but I have to expect their lawyers have spent considerable time to ensure they are not legally exposed which is likely backed up by extensive testing on the engineering side to show compliance .... perhaps not 100% compliance, but enough to make the lawyers happy.

That is a completely acceptable usage of the term "carte blanche" which means to do or say as you please.

There is no frame/board around the ceramic tube. The rendering is low resolution and is making the glass-envelope appear as such perhaps the way you are interpreting it.

I am not implying this is a simple problem to solve, but the only people who normally get rich from solving simple problems are criminals, lawyers and politicians.

Virgil, what is the SAE standard governing ice/snow buildup on headlights and the appropriate testing methods?

127.0.0.1

Flashlight Enthusiast

SemiMan has a point.

the rules govern internal humidity but what about the hard to find info on external frost, ice, humidity, or crap stuck to lens ?

can find lots on chemicals and grit on the external surface, but not frost or ice

internal heat test is about how low can the heat be kept, not about maintaining a specific warm temp

the rules govern internal humidity but what about the hard to find info on external frost, ice, humidity, or crap stuck to lens ?

can find lots on chemicals and grit on the external surface, but not frost or ice

internal heat test is about how low can the heat be kept, not about maintaining a specific warm temp

Last edited:

The manufacturer of the "replacement laser bulb" could test, as an assembly, the combination of the bulb and the headlight, for photometrics, corrosion, humidity, vibration, dust, spray, incursion, etc. The "replacement bulb" would not be tested for compliance per-se but the combination.

...and even if the results came back happy, (1) it still wouldn't solve the lens-frost problem and (2) it still wouldn't satisfy the legal requirements.

It would be difficult to form a legal argument that the installation of the new "headlight assembly" which passes all requisite SAE requirements is either unsafe or violates specific laws

It would be simple. SAE requirements do not have force of law. The relevant regulation is FMVSS 108. It incorporates some provisions from various versions of various SAE documents, but that's the extent of any SAE relevance. Moreover, headlamps must use approved light sources. Whoever wants to can do the relevant work to add a new light source to the list, and then that party becomes legally responsible for those specifications and how they interact with the rest of the applicable laws and regs. And since there are parts of those laws and regs that mean each and every headlamp has to be designed to accept one (and only one) kind of light source, your argument fails.

to my knowledge, 108 /SAE does not call out specific manufacturing methods, only test methods and validation for the design

True, but irrelevant.

creation of the assembly by a trained/approved VAR could be acceptable

I understand that's how it works in your imagination, but it's not how it works in the real world.

I am surprised that Philips is advocating/marketing their XtremeVision LED fog bulbs in the U.S. without consideration to the vehicle they are being installed

Not surprising at all; fog lamps are not Federally regulated.

There is no frame/board around the ceramic tube.

As you wish.

I am not implying this is a simple problem to solve, but the only people who normally get rich from solving simple problems are criminals, lawyers and politicians.

That is a "shrug" of an assessment, typical of those who don't understand the issues involved, but think they do. It's like "Well, all politicians lie" or "Democrats and Republicans are equally bad", or "You can make the data say anything you want" or "There are lies, damned lies, and statistics" (or, most of all, "Aw, those grapes were sour anyhow"): a glib little quip that doesn't come close to any real understanding of the issue and does nothing to move the ball down the field.

Virgil, what is the SAE standard governing ice/snow buildup on headlights and the appropriate testing methods?

There isn't one. That does not mean, however, that NHTSA would be forced to say "Oh, geeze, our hands are tied, we'd like to be able to address this safety issue, but there's no SAE standard or specific provision in FMVSS 108 requiring that headlamps remain effective in winter, so we're stuck not being able to do anything, darnit!". That's just not how it works. NHTSA routinely finds (and forces recalls and issues penalties for) unreasonable and unlawful safety defects, even in vehicles and components duly certified as meeting all applicable provisions of all applicable Federal Motor Vehicle Safety Standards.

But most of this is moot; a small bit of detective work (i.e., I used Google) reveals that the inventor of this latest toy is the head of a company with a product line consisting entirely of illegal, unsafe vehicle lighting equipment hyped as "upgrades". This is just the latest in a long line. Babble about licensing aside, he won't be pitching to makers of new vehicles or headlamps, he'll be pitching to his usual crowd of Ricky Racer and Tommy Tuner and their respective girlfriends who Ricky and Tommy think are sufficiently impressed by blingy lights to get undressed and give it up for Ricky and Tommy.

Last edited:

Alaric Darconville

Flashlight Enthusiast

Just an update in this trainwreck.

If you send that image to the NHTSA (and any links to their idiocy), be sure not to blot their names.

Similar threads

- Replies

- 39

- Views

- 5K

- Replies

- 1

- Views

- 1K