pbarrette

Enlightened

Hi all,

Here is my first Luxeon based Mod, completed only yesterday:

The ArcLuxAAA:

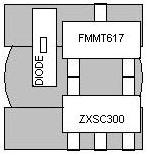

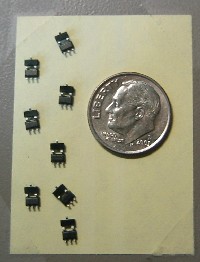

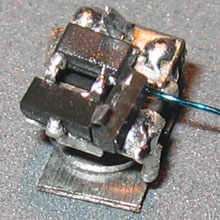

The power behind this light comes from the well known Zetex ZXSC300 circuit which has been hand soldered by myself. I use a circuit layout which allows me to ditch the PCB entirely and solder the components directly to each other. This gives me a much smaller circuit size since I can also work in 3 dimensions.

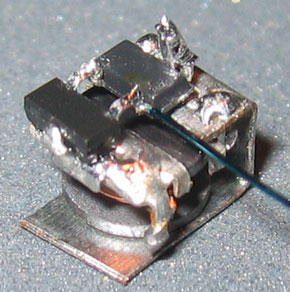

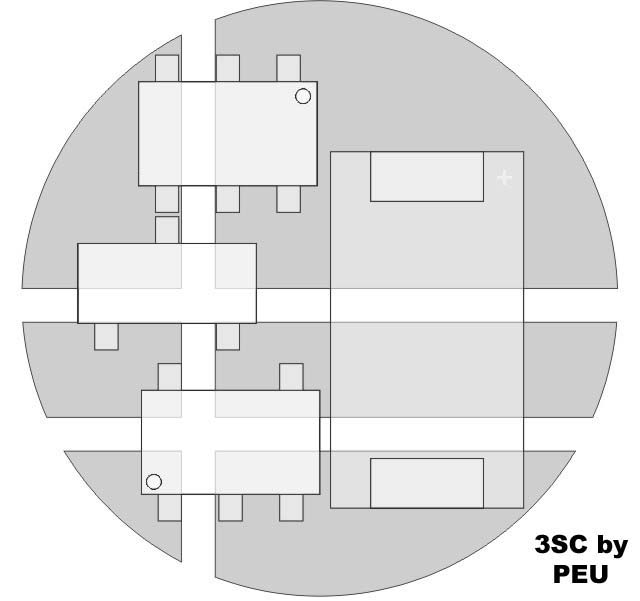

Here's a picture of the basic circuit before the schottkey diode and output capacitor have been added:

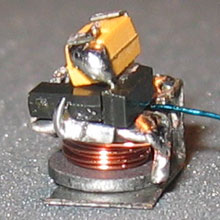

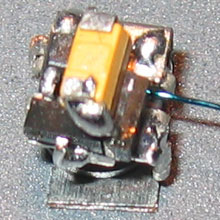

The addition of the diode and capacitor add an additional 2-3mm of height to the circuit, though I forgot to take a picture of that stage of construction.

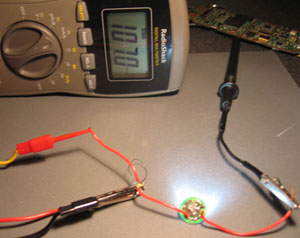

This circuit outputs 150mA from a fresh AAA alkaline and 147mA from a NiMH to drive a 1W PWAJ binned Luxeon HD emitter. I would have used a better bin, but that's all I've got folks.

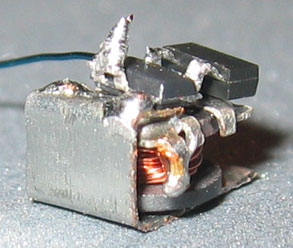

I have been working on a Solitaire based Lux mod where space for the pill is at a premium. The ArcAAA head, on the other hand, is positively roomy in comparison, and the on/off switching is much more simple to work with. This allowed me to add a small heatsink to my pill to help keep the Luxeon bright and safe.

The heatsink is formed from an aluminum tube which is slotted along the length and has two tabs at one end. The slot allows me to both fit the tube over the circuit and adjust the diameter to provide solid contact with the light head. The tabs are bent inwards to make contact with the Luxeon's heatsinking lug on the bottom of the LED.

With the addition of the heatsinking, I could probably get away with using 2 1/2-AAA's which would give me ~350mA through the Luxeon. I don't have any of those batteries yet, so I am unable to test the heatsinking ability at that current. I can say that the head itself gets extremely warm at 350mA, but when the body is attached to the head there should be some decent thermal transfer to the body as well.

As it stands, the heatsink performs wonderfully with the default 150mA draw from 1xAAA. The light warms up a little, but stabilizes at ~5mins with a temperature that is well within the comfort range of bare skin.

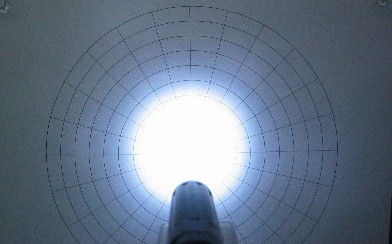

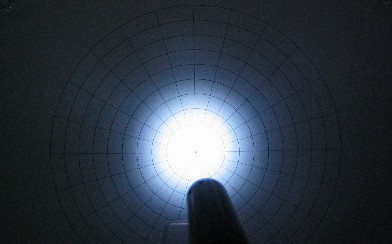

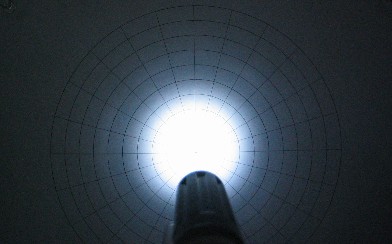

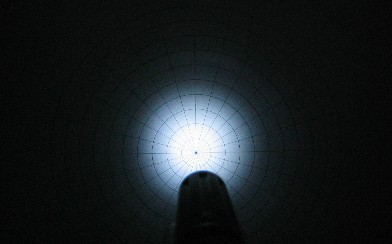

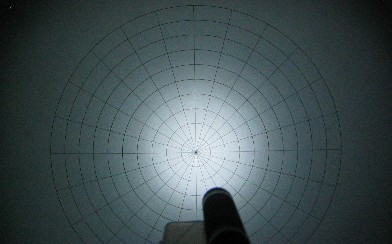

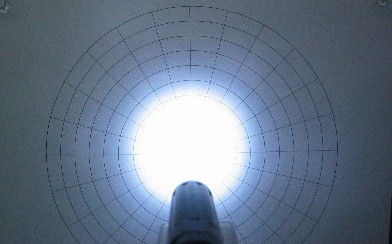

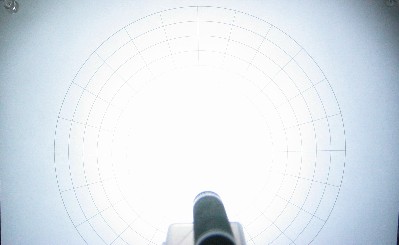

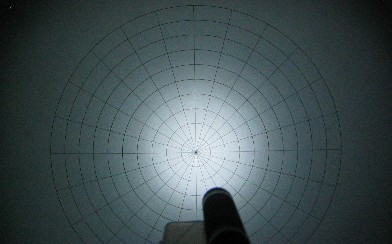

Drilling the reflector of the ArcAAA's head, I found that the stock reflector does, in fact, collimate the light output somewhat. A good indication of this fact is that a decent portion of the yellow phosphor is visible in the reflector when looking at the light head on:

Also, the reflection is nicely visible in this heavily underexposed shot with the light on:

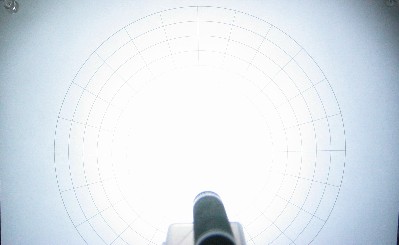

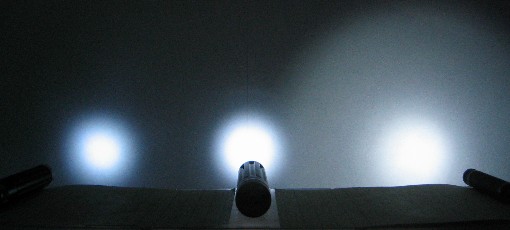

This produces a small hotspot with a lot of sidespill, which is clearly visible in the beamshots.

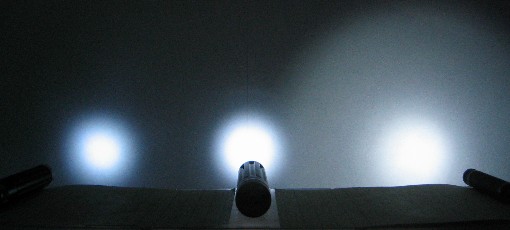

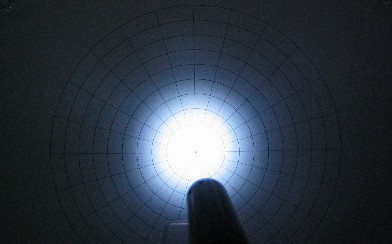

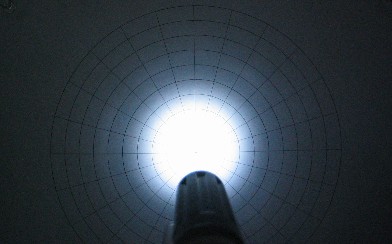

And, what flashlight mod would be complete without beamshots?

So here you are:

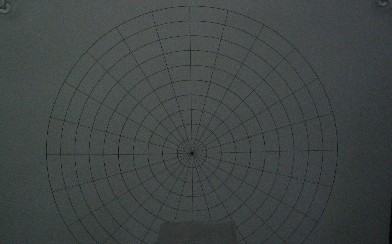

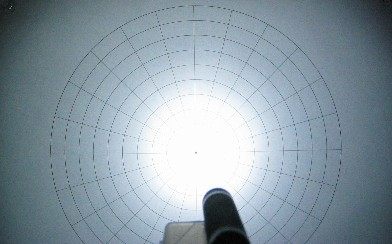

The target with ambient light at Exposure setting #1:

The lights are, in order from left to right:

Xnova 3LED 1xAAA

Xnova 5LED 1xAA

ArcLuxAAA

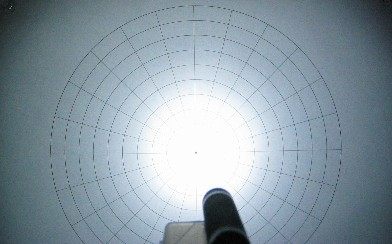

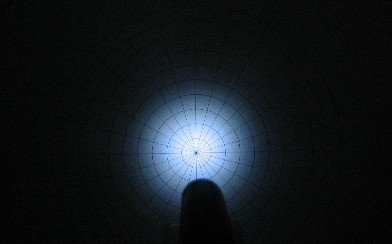

At Exposure setting #1 (Exposure set from ambient light):

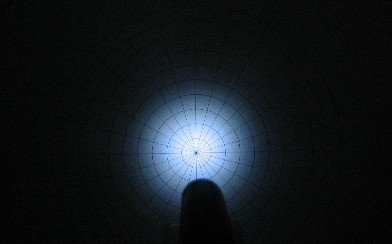

At Exposure setting #2 (Exposure set from Xnova AAA):

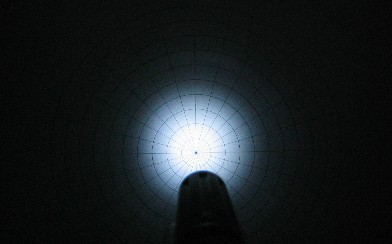

At Exposure setting #3 (Exposure set from ArcLuxAAA):

Now here they are lined up next to each other:

Thanks for having a look,

pb

Here is my first Luxeon based Mod, completed only yesterday:

The ArcLuxAAA:

The power behind this light comes from the well known Zetex ZXSC300 circuit which has been hand soldered by myself. I use a circuit layout which allows me to ditch the PCB entirely and solder the components directly to each other. This gives me a much smaller circuit size since I can also work in 3 dimensions.

Here's a picture of the basic circuit before the schottkey diode and output capacitor have been added:

The addition of the diode and capacitor add an additional 2-3mm of height to the circuit, though I forgot to take a picture of that stage of construction.

This circuit outputs 150mA from a fresh AAA alkaline and 147mA from a NiMH to drive a 1W PWAJ binned Luxeon HD emitter. I would have used a better bin, but that's all I've got folks.

I have been working on a Solitaire based Lux mod where space for the pill is at a premium. The ArcAAA head, on the other hand, is positively roomy in comparison, and the on/off switching is much more simple to work with. This allowed me to add a small heatsink to my pill to help keep the Luxeon bright and safe.

The heatsink is formed from an aluminum tube which is slotted along the length and has two tabs at one end. The slot allows me to both fit the tube over the circuit and adjust the diameter to provide solid contact with the light head. The tabs are bent inwards to make contact with the Luxeon's heatsinking lug on the bottom of the LED.

With the addition of the heatsinking, I could probably get away with using 2 1/2-AAA's which would give me ~350mA through the Luxeon. I don't have any of those batteries yet, so I am unable to test the heatsinking ability at that current. I can say that the head itself gets extremely warm at 350mA, but when the body is attached to the head there should be some decent thermal transfer to the body as well.

As it stands, the heatsink performs wonderfully with the default 150mA draw from 1xAAA. The light warms up a little, but stabilizes at ~5mins with a temperature that is well within the comfort range of bare skin.

Drilling the reflector of the ArcAAA's head, I found that the stock reflector does, in fact, collimate the light output somewhat. A good indication of this fact is that a decent portion of the yellow phosphor is visible in the reflector when looking at the light head on:

Also, the reflection is nicely visible in this heavily underexposed shot with the light on:

This produces a small hotspot with a lot of sidespill, which is clearly visible in the beamshots.

And, what flashlight mod would be complete without beamshots?

So here you are:

The target with ambient light at Exposure setting #1:

The lights are, in order from left to right:

Xnova 3LED 1xAAA

Xnova 5LED 1xAA

ArcLuxAAA

At Exposure setting #1 (Exposure set from ambient light):

At Exposure setting #2 (Exposure set from Xnova AAA):

At Exposure setting #3 (Exposure set from ArcLuxAAA):

Now here they are lined up next to each other:

Thanks for having a look,

pb