Hi guys,

Instead of adding this post mid stream in some current thread, I decided to start fresh. For the most part, the McE2S has hit the street in its original design and has functioned reasonably well. However, with many of these in use and great feed back from users, some issues have been identified. Hopefully the switch can be improved and refined as more experience is logged.

First off, the white nylon boot jam nuts often require individual de burring, additional conter sinking and hole enlargement. Having these parts machined was an expensive mistake on my part. I have since contracted for an injection mold and now the nylon nut is a molded part. Although the part does not comply completely with my design, it is a vast improvement which is good snce it was real expensive to get the dang mold made. /ubbthreads/images/graemlins/icon15.gif If you have a functioning white nylon nut, there is no reason to replace it. I am willing to replace any of these nuts for users if you will mail me a SASE in which I can place the molded nut and drop it in the mail back to you.

With some input and observations from both Bernhard and kj, it has come to my attention that in some cases, the isolating O-ring on the main body of the switch module will partially bind in the battery tube. Lubicrating the O-ring typically takes care of this but it is a work around. I believe that this is a result of tolerances stacking in an unhelpful direction. The bore in the tube is at the low side, the groove diameter in the main body is at the high side and to compound the interference, the O-ring might be fat. I had no idea that the common AS568A Dash Number O-rings were both over the specified diameter so much as well as allowed to vary so much in dimension. The original design calls out for a #010 O-ring used on the button as a retaining O-ring and a #011 O-ring as this isolating O-ring. With some limited testing, it seems that the solution is to use a #010 O-ring for isolation if yours is the case where the #011 is binding in the battery tube (thanks Bernhard and kj :thumbsup). I am now switching my build of these McE2S's to using the #010 for the isolating O-ring. My only real concern is that in the case of a raw Al light that this additional slop might allow the edge of the PCB to contact the side of the cap and provide continuity at unwanted times. My experimenting so far has not shown this to be the case. I need to contact Wayne and suggest he start supplying

the McE2S kits with 2 ea. of the #010 O-rings. Man, I have a bunch of #011 O-rings if anyone needs them! /ubbthreads/images/graemlins/icon15.gif /ubbthreads/images/graemlins/smile.gif

If any of you feel that your switch is being hindered due to the #011 O-ring, again, I will offer a free upgrade if you will mail me a SASE. I want to point out that I have built many of these switches and not noticed this problem! It may be, in my defense, that since I use the same host for testing all of these switches I have just not encountered this adverse condition. In the fewer, complete builds, I have yet to see this problem but given the wide open population that these switches are entering into, who knows what you guys will find! /ubbthreads/images/graemlins/ohgeez.gif I have been using the nygel as a lubrication but it seems to me that this grease tends to thicken noticibly over time?!?!? I am now wondering if I should switch to silicone instead. /ubbthreads/images/graemlins/icon3.gif To my limited knowldge, the EPDM material these O-rings are made of is compatible to either the nygel or silicone grease but is NOT compatible with petroleum greases. I am starting to think that the isolating O-ring should be used dry; especially after switching to the #010. /ubbthreads/images/graemlins/icon3.gif

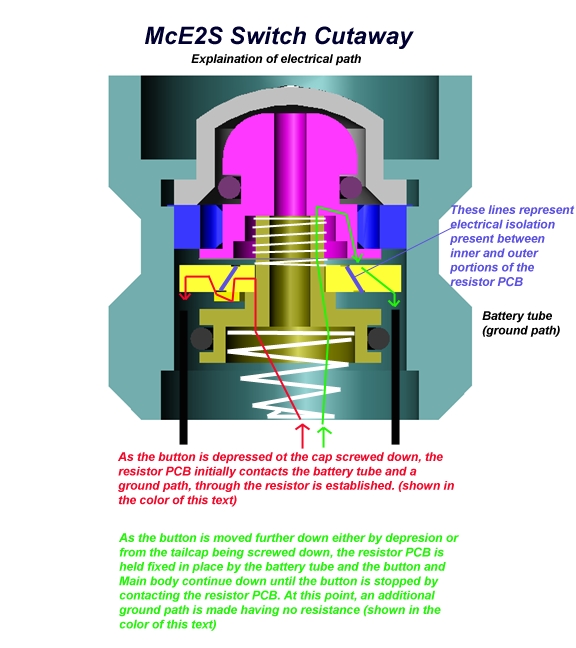

Some of you guys have decided that you want less stroke from low to high and you have modified the height of the stem on the main body which closes the gap between the button and the resistor PCB. The result is a shorter stroke. This is fine but subject to personal preference and I think the stock format needs to remain with a fair distance between low and high. /ubbthreads/images/graemlins/icon3.gif

Well in closing this initial post, I can only thank all of you who have chosen to use these switches and as a group, I expect we can improve on them and I acknowledge that there is always room for improvement but please bear in mind that my resources are limited so viability will be tempered by budget, or lack thereof. /ubbthreads/images/graemlins/blush.gif For most of you, this post goes much deeper into the design than you want to go. I hope that this disclosure does not undermine your confidence in these switches but does provide insight for those who are interested. I am comfortable in claiming that by and large, the switch has proven itself to be a functional and reliable solution and enhancement bringing a new level of illumination to existing tools! (dim though the level may be /ubbthreads/images/graemlins/nana.gif )

Instead of adding this post mid stream in some current thread, I decided to start fresh. For the most part, the McE2S has hit the street in its original design and has functioned reasonably well. However, with many of these in use and great feed back from users, some issues have been identified. Hopefully the switch can be improved and refined as more experience is logged.

First off, the white nylon boot jam nuts often require individual de burring, additional conter sinking and hole enlargement. Having these parts machined was an expensive mistake on my part. I have since contracted for an injection mold and now the nylon nut is a molded part. Although the part does not comply completely with my design, it is a vast improvement which is good snce it was real expensive to get the dang mold made. /ubbthreads/images/graemlins/icon15.gif If you have a functioning white nylon nut, there is no reason to replace it. I am willing to replace any of these nuts for users if you will mail me a SASE in which I can place the molded nut and drop it in the mail back to you.

With some input and observations from both Bernhard and kj, it has come to my attention that in some cases, the isolating O-ring on the main body of the switch module will partially bind in the battery tube. Lubicrating the O-ring typically takes care of this but it is a work around. I believe that this is a result of tolerances stacking in an unhelpful direction. The bore in the tube is at the low side, the groove diameter in the main body is at the high side and to compound the interference, the O-ring might be fat. I had no idea that the common AS568A Dash Number O-rings were both over the specified diameter so much as well as allowed to vary so much in dimension. The original design calls out for a #010 O-ring used on the button as a retaining O-ring and a #011 O-ring as this isolating O-ring. With some limited testing, it seems that the solution is to use a #010 O-ring for isolation if yours is the case where the #011 is binding in the battery tube (thanks Bernhard and kj :thumbsup). I am now switching my build of these McE2S's to using the #010 for the isolating O-ring. My only real concern is that in the case of a raw Al light that this additional slop might allow the edge of the PCB to contact the side of the cap and provide continuity at unwanted times. My experimenting so far has not shown this to be the case. I need to contact Wayne and suggest he start supplying

the McE2S kits with 2 ea. of the #010 O-rings. Man, I have a bunch of #011 O-rings if anyone needs them! /ubbthreads/images/graemlins/icon15.gif /ubbthreads/images/graemlins/smile.gif

If any of you feel that your switch is being hindered due to the #011 O-ring, again, I will offer a free upgrade if you will mail me a SASE. I want to point out that I have built many of these switches and not noticed this problem! It may be, in my defense, that since I use the same host for testing all of these switches I have just not encountered this adverse condition. In the fewer, complete builds, I have yet to see this problem but given the wide open population that these switches are entering into, who knows what you guys will find! /ubbthreads/images/graemlins/ohgeez.gif I have been using the nygel as a lubrication but it seems to me that this grease tends to thicken noticibly over time?!?!? I am now wondering if I should switch to silicone instead. /ubbthreads/images/graemlins/icon3.gif To my limited knowldge, the EPDM material these O-rings are made of is compatible to either the nygel or silicone grease but is NOT compatible with petroleum greases. I am starting to think that the isolating O-ring should be used dry; especially after switching to the #010. /ubbthreads/images/graemlins/icon3.gif

Some of you guys have decided that you want less stroke from low to high and you have modified the height of the stem on the main body which closes the gap between the button and the resistor PCB. The result is a shorter stroke. This is fine but subject to personal preference and I think the stock format needs to remain with a fair distance between low and high. /ubbthreads/images/graemlins/icon3.gif

Well in closing this initial post, I can only thank all of you who have chosen to use these switches and as a group, I expect we can improve on them and I acknowledge that there is always room for improvement but please bear in mind that my resources are limited so viability will be tempered by budget, or lack thereof. /ubbthreads/images/graemlins/blush.gif For most of you, this post goes much deeper into the design than you want to go. I hope that this disclosure does not undermine your confidence in these switches but does provide insight for those who are interested. I am comfortable in claiming that by and large, the switch has proven itself to be a functional and reliable solution and enhancement bringing a new level of illumination to existing tools! (dim though the level may be /ubbthreads/images/graemlins/nana.gif )