DM51

Flashaholic

Bomb-proof dive light mod – an Incan version

This is a mod done on a "Bomb-proof host", as sold here, with discussion continued here.

LED mods of this host have already been done, including:

P7 version by wquiles

MC-E version by olrac

4x High-CRI P4 version by MWClint

I decided to go the Incan route with mine.

Incan light underwater has disadvantages at medium and long distances, due to the absorption by water of red (longer-wavelength) light, but for short distances less than 5m (15ft) the color rendition is greatly superior to that of LED light, which is already heavily over-weighted in blue. For viewing underwater life in true colors, including during the daytime, incan light is by far the best.

I settled on 2x AW "C" Li-Ion cells and a WA 1111 bulb. The reflector would be a Fivemega New Gen Hybrid FM2 Reflector, which can be made to fit perfectly into the light's head.

I spent some time thinking about which bulb-holder to use, and eventually decided on the G4 socket that is used with the Fivemega G4 D26 Sunlight reflector. The D26 reflector itself would obviously not be required.

The advantages of using this bulb-holder would be twofold: first, it has a built-in spring for one terminal, the other terminal being grounded; and second, in a suitably threaded adapter housing, the screw adjustment could be used to focus the bulb precisely in the reflector. The adapter housing would have to be specially made to fit correctly inside the body of the light.

Work to the body of the light.

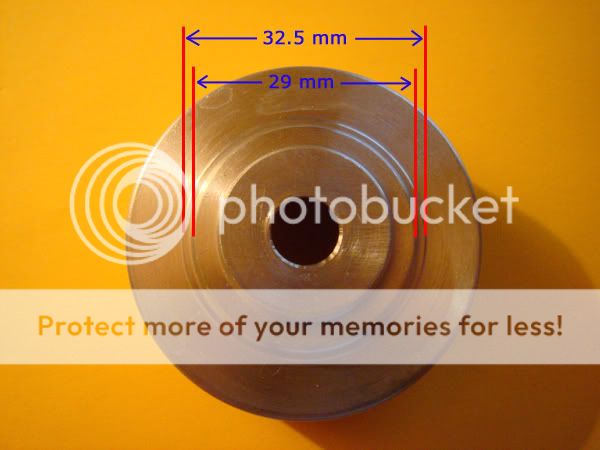

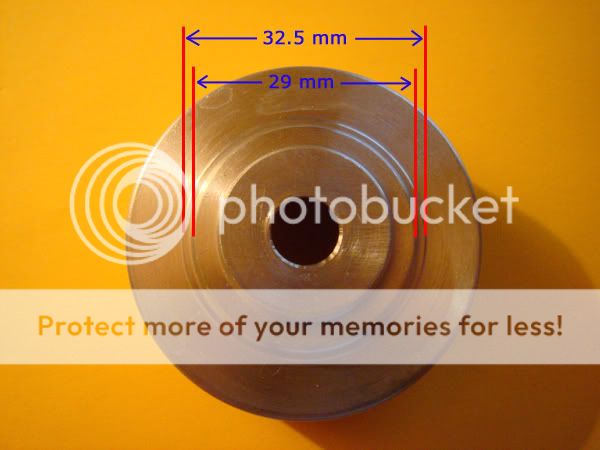

It was not necessary to take the head/body join apart. The hole in the head had to be enlarged to take the base of the reflector, which has a 29 mm diameter protrusion with a shallow 32.5 mm dia step to it.

With the hole enlarged to 29 mm, and the body tube's internal diameter being 30.5 mm, this leaves a 0.75 mm lip at the head end of the tube for the socket holder to rest on. On the reflector side, a shallow 32.5 mm diameter recess was left for the stepped base of the reflector (as mentioned above).

Left: before; Right: after

The HA on the end of the body tube was ground down with a dremel to expose the bare metal, as it would need to make electrical contact with the tailcap. This was a quick and easy job.

Left: before; Right: after

Modification of the reflector

There is a lip on the edge of the reflector which was machined off to reduce its diameter so it would fit inside the head.

Left: before; Right: after

The reflector is a shade too deep to fit. The lens needs to seat firmly on to the shoulder inside the head. 10 minutes of careful sandpapering took the rim of the reflector down ~0.05mm – enough for a perfect fit. This obviously produced some tiny particles of Al dust; all that was necessary was to blow them off. At no time during any process was the reflective surface itself touched!

Left: before; Right: after

Socket holder

This was the key component that had to be made.

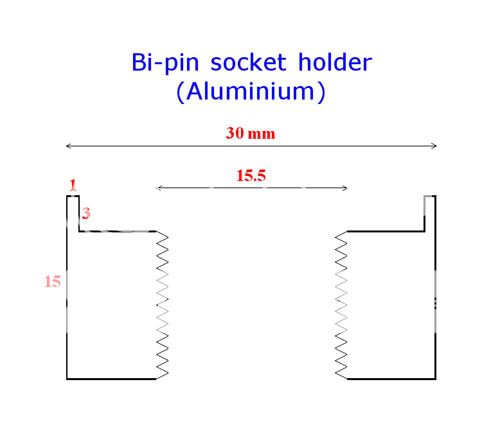

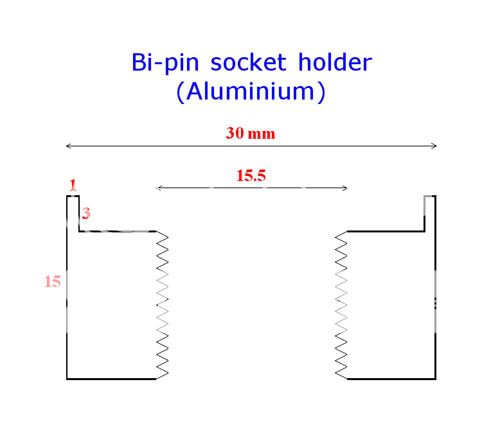

Drawing:

Finished component, machined in Aluminium:

Socket installed in holder:

Tailcap, soft contact

The idea here was to make the electrical/battery tail contact a soft one, with some give, instead of the battery having a hard contact against the tailcap. A 34mm diameter thin-gauge steel disc was seated inside the tailcap using "sticky fixers", which are pads with double-sided adhesive. The sticky pads give some shock-absorbency to the tail end.

Battery tube

I'm lazy, lol. One day I'll make a proper delrin tube for the 2x "C" cells, but in the meantime I've rolled them in paper to ensure a snug fit and prevent rattling. It's not very professional and I can sense the pained expressions on the faces of the real CPF modders here when they see such a travesty, but paper actually works fine. In fact, it's the perfect solution to a lot of the "how do I stop my cells rattling" posts that appear around the forum.

Completion

I am delighted with this build. The host is extremely sturdy, and the light will provide ~800 lumens for 45 mins run-time. I spent some time adjusting the focus, using the screw action of the bulb holder to achieve the optimum position of the filament. This Fivemega reflector is superb. Below are 2 beamshots, 1 taken at normal exposure (¼ sec at f2.8) and the second one stopped right down to 1/250 sec at f2.8. These pics were taken in daylight with the curtains drawn. The target is a high ceiling, 12½ feet from the light. Before anyone complains of the tint, the ceiling is NOT white – it is a sort of peach color (chosen by Mrs. DM51).

¼ sec at f2.8:

1/250 sec at f2.8:

Possible variants

An alternative bulb holder would be the Fivemega T1.5 holder. It has the same threading (it fits the same D26 reflector), so it would be easy to swap between the two. This would enable the use of smaller bulbs such as the FM1794.

AW's soon-to-be-released IMR 26500 cells (C-size) will be ~3mm shorter (total ~6mm for 2 cells) than the discontinued "C" Li-Ions, but with a spacer they would work very well with this set up.

I'll be taking it diving soon, and will report back.

This is a mod done on a "Bomb-proof host", as sold here, with discussion continued here.

LED mods of this host have already been done, including:

P7 version by wquiles

MC-E version by olrac

4x High-CRI P4 version by MWClint

I decided to go the Incan route with mine.

Incan light underwater has disadvantages at medium and long distances, due to the absorption by water of red (longer-wavelength) light, but for short distances less than 5m (15ft) the color rendition is greatly superior to that of LED light, which is already heavily over-weighted in blue. For viewing underwater life in true colors, including during the daytime, incan light is by far the best.

I settled on 2x AW "C" Li-Ion cells and a WA 1111 bulb. The reflector would be a Fivemega New Gen Hybrid FM2 Reflector, which can be made to fit perfectly into the light's head.

I spent some time thinking about which bulb-holder to use, and eventually decided on the G4 socket that is used with the Fivemega G4 D26 Sunlight reflector. The D26 reflector itself would obviously not be required.

The advantages of using this bulb-holder would be twofold: first, it has a built-in spring for one terminal, the other terminal being grounded; and second, in a suitably threaded adapter housing, the screw adjustment could be used to focus the bulb precisely in the reflector. The adapter housing would have to be specially made to fit correctly inside the body of the light.

Work to the body of the light.

It was not necessary to take the head/body join apart. The hole in the head had to be enlarged to take the base of the reflector, which has a 29 mm diameter protrusion with a shallow 32.5 mm dia step to it.

With the hole enlarged to 29 mm, and the body tube's internal diameter being 30.5 mm, this leaves a 0.75 mm lip at the head end of the tube for the socket holder to rest on. On the reflector side, a shallow 32.5 mm diameter recess was left for the stepped base of the reflector (as mentioned above).

Left: before; Right: after

The HA on the end of the body tube was ground down with a dremel to expose the bare metal, as it would need to make electrical contact with the tailcap. This was a quick and easy job.

Left: before; Right: after

Modification of the reflector

There is a lip on the edge of the reflector which was machined off to reduce its diameter so it would fit inside the head.

Left: before; Right: after

The reflector is a shade too deep to fit. The lens needs to seat firmly on to the shoulder inside the head. 10 minutes of careful sandpapering took the rim of the reflector down ~0.05mm – enough for a perfect fit. This obviously produced some tiny particles of Al dust; all that was necessary was to blow them off. At no time during any process was the reflective surface itself touched!

Left: before; Right: after

Socket holder

This was the key component that had to be made.

Drawing:

Finished component, machined in Aluminium:

Socket installed in holder:

Tailcap, soft contact

The idea here was to make the electrical/battery tail contact a soft one, with some give, instead of the battery having a hard contact against the tailcap. A 34mm diameter thin-gauge steel disc was seated inside the tailcap using "sticky fixers", which are pads with double-sided adhesive. The sticky pads give some shock-absorbency to the tail end.

Battery tube

I'm lazy, lol. One day I'll make a proper delrin tube for the 2x "C" cells, but in the meantime I've rolled them in paper to ensure a snug fit and prevent rattling. It's not very professional and I can sense the pained expressions on the faces of the real CPF modders here when they see such a travesty, but paper actually works fine. In fact, it's the perfect solution to a lot of the "how do I stop my cells rattling" posts that appear around the forum.

Completion

I am delighted with this build. The host is extremely sturdy, and the light will provide ~800 lumens for 45 mins run-time. I spent some time adjusting the focus, using the screw action of the bulb holder to achieve the optimum position of the filament. This Fivemega reflector is superb. Below are 2 beamshots, 1 taken at normal exposure (¼ sec at f2.8) and the second one stopped right down to 1/250 sec at f2.8. These pics were taken in daylight with the curtains drawn. The target is a high ceiling, 12½ feet from the light. Before anyone complains of the tint, the ceiling is NOT white – it is a sort of peach color (chosen by Mrs. DM51).

¼ sec at f2.8:

1/250 sec at f2.8:

Possible variants

An alternative bulb holder would be the Fivemega T1.5 holder. It has the same threading (it fits the same D26 reflector), so it would be easy to swap between the two. This would enable the use of smaller bulbs such as the FM1794.

AW's soon-to-be-released IMR 26500 cells (C-size) will be ~3mm shorter (total ~6mm for 2 cells) than the discontinued "C" Li-Ions, but with a spacer they would work very well with this set up.

I'll be taking it diving soon, and will report back.