Osprey_Guy

Enlightened

CPF member Aikiman44 (aka Jay) has been keeping me busy of late. Just last week I finished up his new knife, my latest Topo Gigio mini-balisong....

http://candlepowerforums.com/vb/showthread.php?t=154340

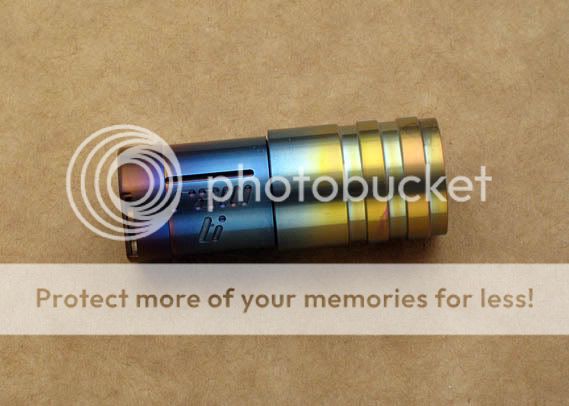

Within days of completing that little project I jumped on his Dam Cham. I spent yesterday and today refinishing and Nitre Bluing it...and if I do say-so myself I think it turned out pretty nice.

I tried to get a decent photo of it, but as usual I was unable to come even close to showing the very high gloss, and the deep, penetrating, jewel-like colors. This is about the best I could do with my limited photography skills:

Jay's leaving town tomorrow for several days...so I won't be shipping this to him until next week. But I wanted to make sure that he at least gets a chance to see a pic of the finished light before he takes off for the long weekend. Jay- I hope you'll be happy with this.

Dennis Greenbaum

http://candlepowerforums.com/vb/showthread.php?t=154340

Within days of completing that little project I jumped on his Dam Cham. I spent yesterday and today refinishing and Nitre Bluing it...and if I do say-so myself I think it turned out pretty nice.

I tried to get a decent photo of it, but as usual I was unable to come even close to showing the very high gloss, and the deep, penetrating, jewel-like colors. This is about the best I could do with my limited photography skills:

Jay's leaving town tomorrow for several days...so I won't be shipping this to him until next week. But I wanted to make sure that he at least gets a chance to see a pic of the finished light before he takes off for the long weekend. Jay- I hope you'll be happy with this.

Dennis Greenbaum