Doug S

Flashlight Enthusiast

Long ago I tested the circuits in the Gen I and Gen II Dorcy 1AAA lights. For some reason that thread was in the LED subforum rather than here in the geeky electronics subforum. That thread can be seen here:

http://www.candlepowerforums.com/vb/showthread.php?t=33478

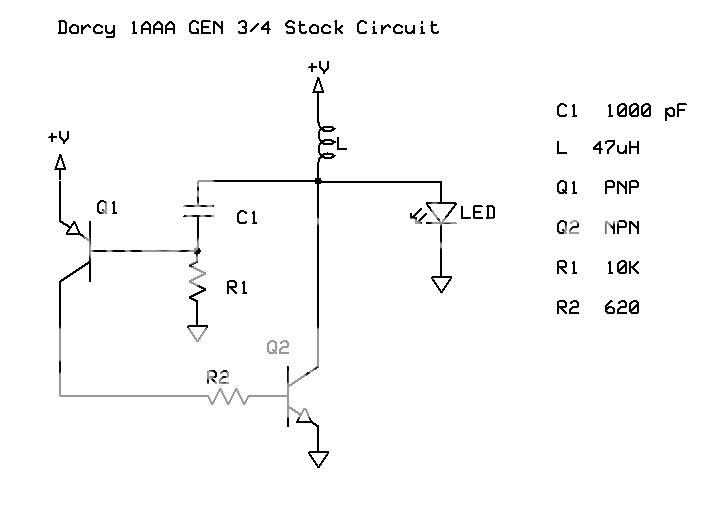

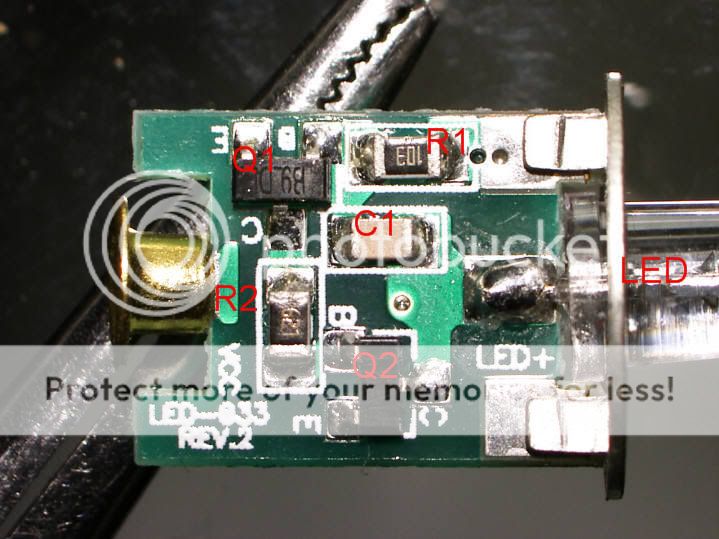

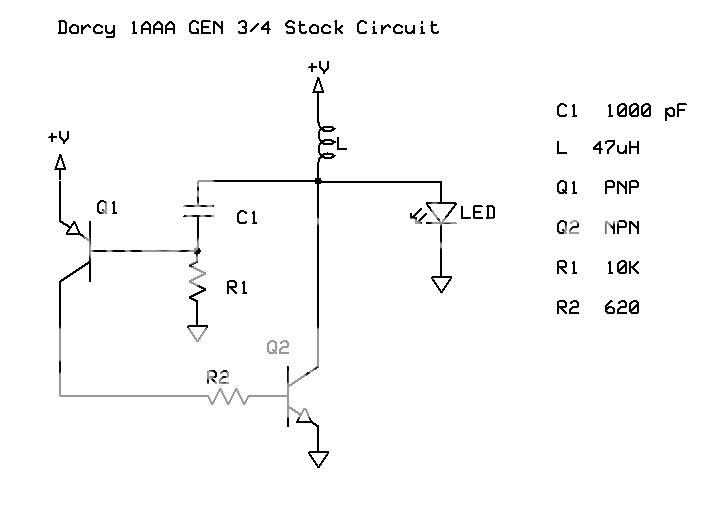

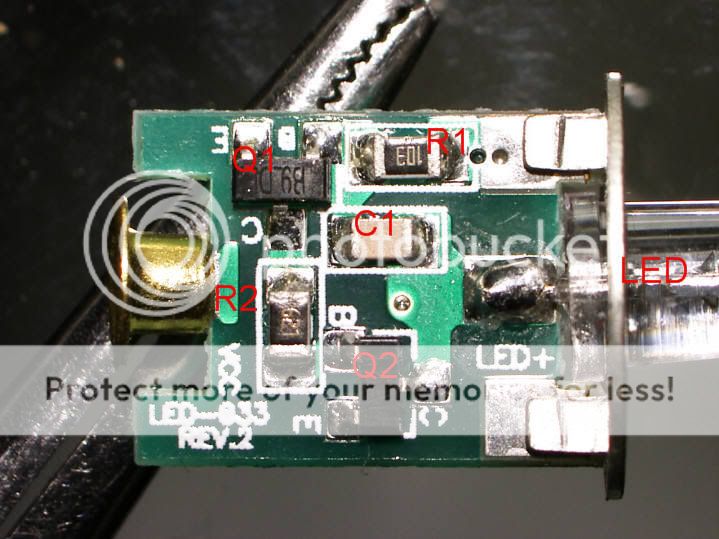

I am starting a new thread here where it probably belongs for the Gen 3 and 4 circuits which are different from the Gen I and II circuits. Gen 3 and 4 are the same circuit and is shown below:

The images directly above were kindly provided by CPF member 1331.

If this circuit looks familiar to some of the oldtimers here, it should. Except for the specific component values, it is the same as the old Brinkmann 2AA LED light circuit that was much discussed a few years back and is drawn by member MrAl in this thread:

http://www.candlepowerforums.com/vb/showpost.php?p=658886&postcount=6

While MrAl's diagram for the Brinkmann version shows the inductor current being continuous (barely), as implemented in the Dorcy the inductor current goes to zero before Q2 turns on for input voltages below about 1.43V.

In common with the earlier Brinkmann circuit, the LED current is in the form of short, high current (up to 500mA peak!!!) pulses with the LED current being zero for the majority of the time. This is an extremely inefficient way to drive a 5mm LED which likely has a peak current rating on the order of 50-100mA.

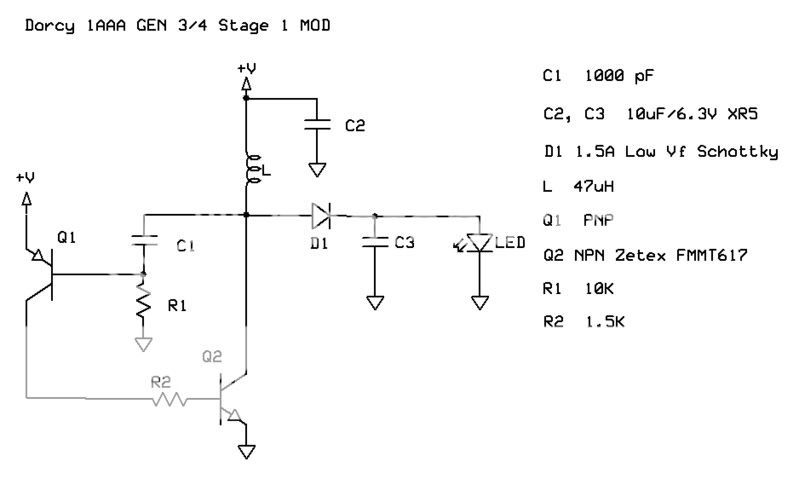

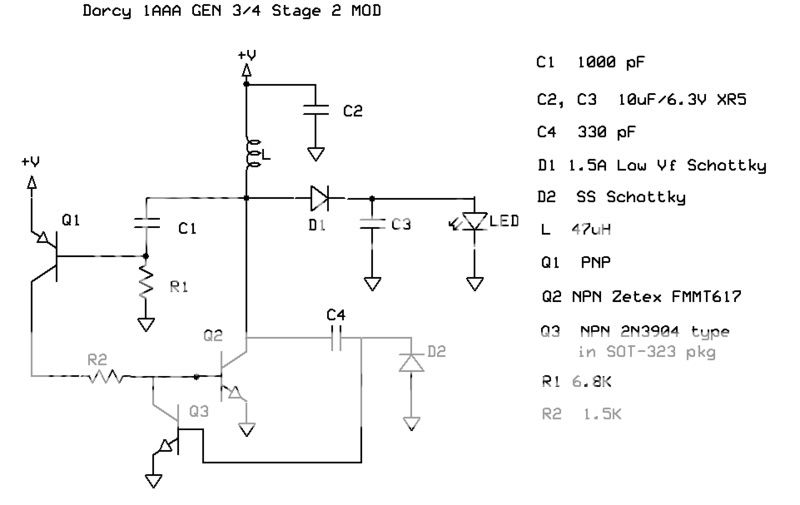

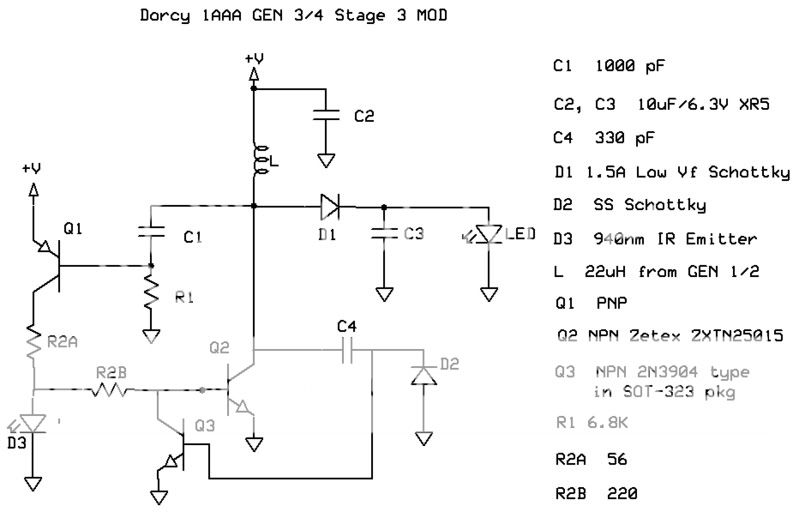

This circuit is very mod friendly as the board is fairly spacious and there are a number of simple mods that will greatly enhance performance. I will be posting details of these mods over the next few days as time permits.

In the meantime, here is a review of three of these mods by CPF member UnknownVT:

http://www.candlepowerforums.com/vb/showthread.php?p=1804176#post1804176

http://www.candlepowerforums.com/vb/showthread.php?t=33478

I am starting a new thread here where it probably belongs for the Gen 3 and 4 circuits which are different from the Gen I and II circuits. Gen 3 and 4 are the same circuit and is shown below:

The images directly above were kindly provided by CPF member 1331.

If this circuit looks familiar to some of the oldtimers here, it should. Except for the specific component values, it is the same as the old Brinkmann 2AA LED light circuit that was much discussed a few years back and is drawn by member MrAl in this thread:

http://www.candlepowerforums.com/vb/showpost.php?p=658886&postcount=6

While MrAl's diagram for the Brinkmann version shows the inductor current being continuous (barely), as implemented in the Dorcy the inductor current goes to zero before Q2 turns on for input voltages below about 1.43V.

In common with the earlier Brinkmann circuit, the LED current is in the form of short, high current (up to 500mA peak!!!) pulses with the LED current being zero for the majority of the time. This is an extremely inefficient way to drive a 5mm LED which likely has a peak current rating on the order of 50-100mA.

This circuit is very mod friendly as the board is fairly spacious and there are a number of simple mods that will greatly enhance performance. I will be posting details of these mods over the next few days as time permits.

In the meantime, here is a review of three of these mods by CPF member UnknownVT:

http://www.candlepowerforums.com/vb/showthread.php?p=1804176#post1804176

Last edited: