Alan B

Flashlight Enthusiast

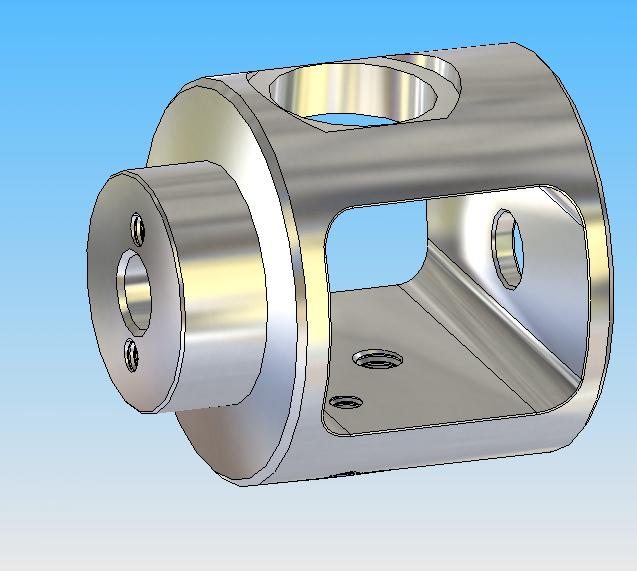

First Article Hotwire Regulator (SN001) shown above, prototype below

For the past year I've been working on a Programmable Hotwire Regulator design. (A Hotwire is a high power incandescent). Many folks on the forums here have contributed including JimmyM, wquiles and others. The goal is to have several regulated hotwire driver choices available in the marketplace. These drivers provide protection for the bulb by soft starting and regulating the voltage (to prevent instaflashing - blowing the bulb, and overloading any battery protection) and to protect the batteries via low voltage and high temperature shutdown. They also allow the battery voltage to be greater than the bulb voltage and facilitate selecting the optimal voltage for the bulb. Bulbs last a lot longer and can be finely tuned for maximum intensity, and the light level will be constant until the battery voltage sags below the regulation level in which case the regulator becomes direct drive and still provides soft start protection for the bulb and battery. Additionally variable intensity is available in the specially developed User Interface to provide reduced output and lengthen battery as well as bulb life.

For those unfamiliar with M@g modified hotwires, you basically put in a higher voltage battery pack, change the bulb, socket, reflector and lens to build a high powered incandescent flashlight. Add this regulator and the battery voltage can be up to twice the bulb voltage for long runtimes and regulated output. A common example of a Hotwire is the so called Mag85, which employs a Welch Allyn 1185 30 watt medical bulb. It produces a very nice focusable white light, and can be overdriven to about 1200 hot tungsten bulb lumens.

This thread is to help me decide if I should build a few of my particular variant of the design for others. Originally I did not intend to build anything, but I have so much time invested and I want a few for myself, so I am considering it. wquiles and JimmyM are planning to build their variants. wquiles' is going to be in a battery carrier for the SF-M6, and JimmyM's is going to work with the KIU base in the D M@g. I will continue to support their efforts as well as developing my own.

My implementation is a D Maglite switch replacement (drop-in) that allows easily reprogramming the CPU without removing it from the M@g. New software may be uploaded or configurations changed easily with a cable to a computer. So each of the three projects are somewhat different and complementary.

At this point I have a working electrical and software prototype in a prototype aluminum "Sled" (shown above). The mechanical design is machined from a solid block of aluminum to fit the M@g and carry the electronics and the bipin bulb socket. The pushbutton switch plugs in through the M@g switch hole.

Standoffs on one end of the "MagSled(tm)" support the bipin bulb socket. The other end has the battery plus contact. The production regulator is designed to work with the existing stop-ring inside the M@g, sitting against it for support the same as the stock switch. A setscrew similar to the stock switch anchors the drop-in and makes the negative connection to the M@g body tube. The bulb socket standoffs can be changed for different bulb heights.

An alternate programming adapter plugs in replacing the switch board. The programming board sticks out of the flashlight and contains a programming socket extension and several pushbuttons for testing, etc.

Programming Adapter Installed

The circuit boards use no surface mount parts, so they can be readily repaired or modded if necessary. CORRECTION: The early boards were all through hole, but they have been redesigned to be a mix of surface mount parts and through-hole parts. The Regulator, Fuse, and FET are through-hole, as are the connectors. The Microprocessor is surface mount as are the resistors and capacitors. The parts are not super-small so service is still reasonable. The schematic is published. All electronic parts are readily available. There is a fuse onboard to protect the batteries in case of a short. This is especially important with unprotected high current cells.

The default user interface software has been optimized for Hotwires and includes variable intensity as well as voltage regulation, soft start, over temperature protection and low voltage cell protection, and a number of options. Changing these options requires reloading the software with a PC and programming adapter. Future versions of the software may have more features and flexibility.

The configuration of the basic regulator would be specified when the device is ordered. Several parameters can be specified - High and Low Bulb Voltage, Battery Cutoff Voltage and more. Standard configurations will be available. The regulator would be constructed, programmed and calibrated. It would be "drop-in", though some adjustments for bulb position within the reflector may be required (changing standoff height). The basic configuration would not include the programming/calibration board.

The optional programming kit would enable the user to reprogram the regulator with a computer. This requires some additional equipment and free software. One programming kit can handle any number of regulators. The programming kit can also be used to upload improved versions of software, change parameters and do software experiments and learn to program microprocessors. The existing software is written in Gnu C, so it is not necessary to work in assembly language, though it is supported as well. The software tools are freely available, though there is some complexity to develop and debug programs in a limited CPU environment such as this. Programming requires two parts - a programming dongle, available from many sources for about $35, and a programming/calibration board that reaches into the flashlight and extends the programming plug. Programming without the programming/calibration board can also be accomplished but it is more difficult to reach into the flashlight. If you wish to change the voltage settings a programming setup is required in the present software. Future software may allow changing some parameters without programming, but this is not yet planned. Customized versions of software by users or third parties are also possible.

Laptop Flashlight Programming in Action

The cost is yet undetermined. I expect to keep it under $100. Some part of this would go to benefit the CP Forums as it has been the vehicle that enabled this collaboration to occur. This detail has not been worked out yet.

This is a feeler thread, not binding in either direction. I may get distracted with other projects and have to put this on hold, and you may change your mind later. I will however use this feeler as the order in which to offer the limited quantities of hardware that do become available, so there is some motivation for posting to this thread and indicating your interest.

I need to know how many units folks are interested in, what battery voltage and type, bulb voltage, type and bulb current you would want, and other requirements you might have.

New Threads:

Discussion/FAQ/Documentation/Questions/Suggestions Thread:

http://www.candlepowerforums.com/vb/showthread.php?t=231656

Order/Sales/Interest Thread:

http://www.candlepowerforums.com/vb/showthread.php?t=231886

Links within this thread and other Historical threads:

Read this FAQ for further details:

http://www.candlepowerforums.com/vb/showpost.php?p=2805117&postcount=160

The Interest List is in post #5:

http://www.candlepowerforums.com/vb/showpost.php?p=2775605&postcount=5

The UI (User Interface) includes variable output, selectable levels, etc is in post #63:

http://www.candlepowerforums.com/vb/showpost.php?p=2785888&postcount=63

Voltage Variations listed in post #95:

http://www.candlepowerforums.com/vb/showpost.php?p=2788521&postcount=95

First Article Review:

http://www.candlepowerforums.com/vb/showthread.php?t=230519

Thanks for your support, comments and input,

-- Alan

Links:

Design Collaboration Part I:

http://www.candlepowerforums.com/vb/showthread.php?t=186291

Design Collaboration Part II:

http://www.candlepowerforums.com/vb/showthread.php?t=209098

Design Collaboration Part III:

http://www.candlepowerforums.com/vb/showthread.php?t=220475

wquiles SF-M6 variant:

http://www.candlepowerforums.com/vb/showthread.php?t=215806

JimmyM's D-M@g variant:

http://www.candlepowerforums.com/vb/showthread.php?t=216160

Summary of Plans

Design, prototype and test electronics and software (done)

Build first prototype mechanical to fit first prototype electronics (done)

First article PCB on order. Metal vendor selected. (done)

Build of first article electronics (done)

Final fit mechanical sled to electronics (done)

First Article out for Review (done)

SMT Redesign (done)

Preparing minor updates (done)

Order Production Metal (done 5/2009)

Production... (approx 7/2009)

Metalwork

Nanomiser is helping me with the mechanical final design and production. Here is a rendering from his CAD software:

5/2009 update:

Metalwork has been fitted and prototypes made under numerical control. I have a very small number of "Sleds". Nanomiser's adjustments to the design worked out very precisely. :thumbsup:

Production Machined Metal is ON ORDER.

Last edited: