Welcome here, Chocablock! :wave:

Difference between these 1W and 3W LEDs is mostly likely in their marketing... and how you cool them.

You see, there's physical limits here you can't get around. In use, there will be a voltage over that LED, a current through it, the product (called Watt) is partly converted into light, the remainder (the bulk of those Watts) becomes heat.

It could be that some LEDs are more efficient, so a larger % goes out as light and less heat remains. But since most of those Watts are turned into heat anyway, differences between LEDs in this regard aren't

that big.

It could be that the substrate of one LED conducts heat much better than another, so it can get rid of heat easier. Or can tolerate a higher operating temperature. But again: for halfway similar LEDs, such differences won't be

that big.

So if they're made from the same materials, with similar dimensions, then the power they can dissipate

WILL be similar.

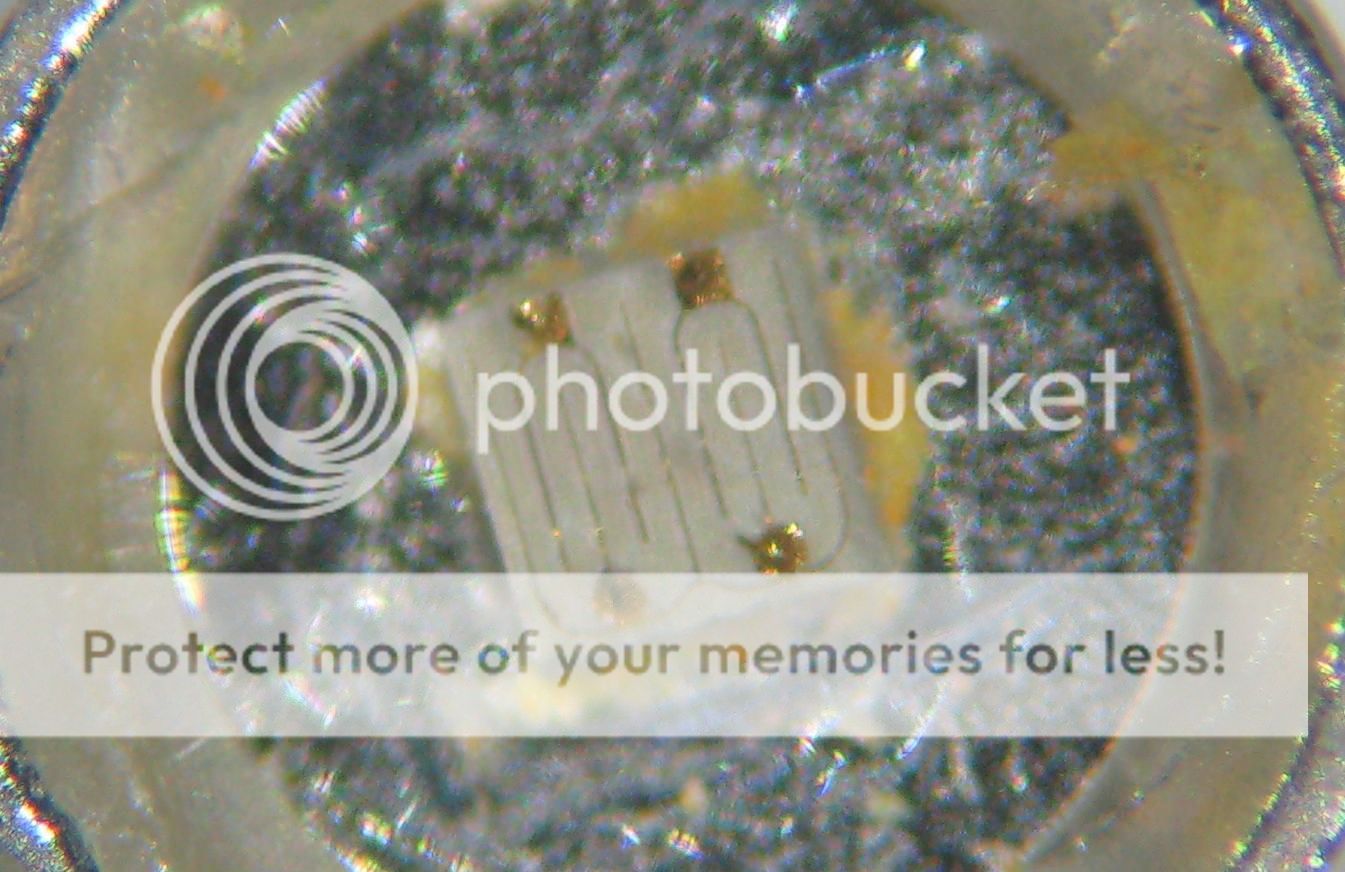

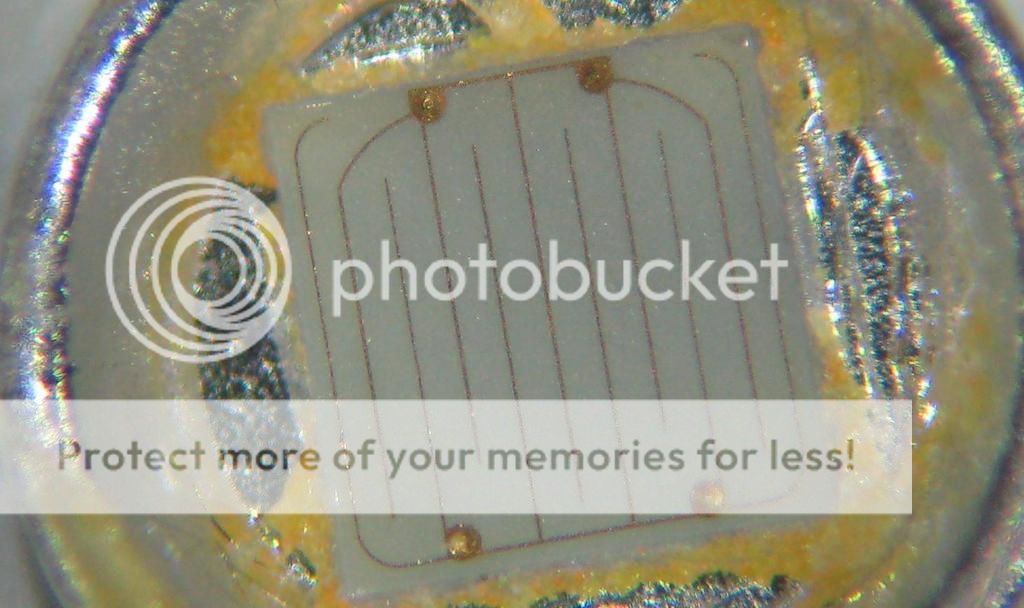

Regardless what supplier says! One manufacturer might be conservative and market these as 1W, while another might do tests with optimally cooled specimens, and market them as 3W. Is that substrate ceramic? Then you can probably get away with >3W if the LED is stuck onto a thick copper plate with cooling paste between ceramic and copper. Is that substrate plastic? Then even 1W might be too much no matter how the LED is cooled. So provide proper cooling, ramp up the power gradually, measure, feel (temperature), calculate, and watch the LED's behavior carefully. And maybe you can find a datasheet for a similar built LED somewhere, to support your findings with some numbers (thermal resistance for die -> substrate, and substrate -> ambient, for various cooling methods, is what you're looking for).

Ive put them on my power supply but the amperage they pull is all over the place.

The amperage they "pull" ? :duh2: If you mean you put 'm on a constant voltage source: better not do that, it's a good way to burn LEDs fast. Always use some way to control the

current through the LED. For example a series resistor, or a dedicated LED driver.