Hi fivemaga (and other CPFers interested)

using this (and not a PM) because I hope someone could give some input and making the sarting idea better ...

I never considered using an insert as the best solution, the main goal always is mounting led/driver/reflector onto an-as-thick-as-possible aluminium "disc", with a semi-press fit into the host.

Primarily because that is the only way to get a good thermal path,

and because the parts chosen by user are always "better" than a ready made "thing" to please the masses.

Now I just noticed that the insert cutout is not a right 90 degree, but features angeled walls.

As I dunno if a machine shop might be able to fit a disc with ease, and because You know the angles You used ...

... is there any chance that You run a small batch of "discs" for Your bodies?

What I think of were an aluminium disc that has a very tight fit and touches all wall parts.

With a cutout at the base for the driver.

Could be pressed/fixed in place by bezel pushing on reflector/optic

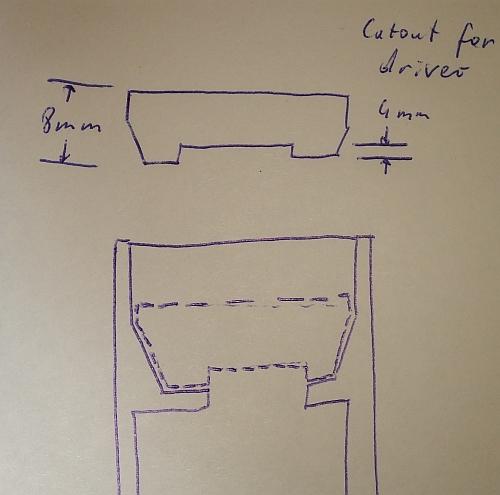

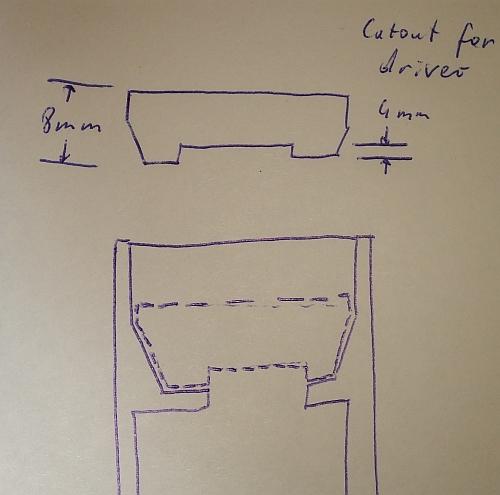

Maybe a pic is better:

(but my painting skills are not)

* the driver cutout with a size like the hole in the bodies,

* all measurements just "over the thumb" and to be improved if possible.

* 4mm + the cutout in the body should be way enough for driver + spring,

* 8 mm thickness is at least enough for led and small reflectors like SS 19 mm.

I might take a small number of such discs, much better than having a shop mill even angles into the body.

Probably there are several other ppl looking for such thing, too?

using this (and not a PM) because I hope someone could give some input and making the sarting idea better ...

I never considered using an insert as the best solution, the main goal always is mounting led/driver/reflector onto an-as-thick-as-possible aluminium "disc", with a semi-press fit into the host.

Primarily because that is the only way to get a good thermal path,

and because the parts chosen by user are always "better" than a ready made "thing" to please the masses.

Now I just noticed that the insert cutout is not a right 90 degree, but features angeled walls.

As I dunno if a machine shop might be able to fit a disc with ease, and because You know the angles You used ...

... is there any chance that You run a small batch of "discs" for Your bodies?

What I think of were an aluminium disc that has a very tight fit and touches all wall parts.

With a cutout at the base for the driver.

Could be pressed/fixed in place by bezel pushing on reflector/optic

Maybe a pic is better:

(but my painting skills are not)

* the driver cutout with a size like the hole in the bodies,

* all measurements just "over the thumb" and to be improved if possible.

* 4mm + the cutout in the body should be way enough for driver + spring,

* 8 mm thickness is at least enough for led and small reflectors like SS 19 mm.

I might take a small number of such discs, much better than having a shop mill even angles into the body.

Probably there are several other ppl looking for such thing, too?