May 2017 discussion in the main HDS thread, #19. Henry actually posted then.Got a link to those old posts? I'm happy to be educated, but I didn't find any posts on this topic with a couple searches and looking through about 20 pages of search results.

And it seems like you were being sarcastic, but it is possible to correlate measurements made with a light meter in an arbitrary reflective box back to measurements made using a spectrometer in an integrating sphere (and I know of at least one company doing exactly that for production measurements, for various reasons.) But it takes a bit of effort to get things to correlate well.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Novatac 120T serial 12269 pics and questions

- Thread starter jon_slider

- Start date

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

Lithium466

Enlightened

Post in thread 'HDS Systems EDC # 19'

https://www.candlepowerforums.com/threads/hds-systems-edc-19.417896/post-5096411

that would be it?

https://www.candlepowerforums.com/threads/hds-systems-edc-19.417896/post-5096411

that would be it?

jon_slider

Flashlight Enthusiast

- Joined

- Mar 31, 2015

- Messages

- 5,150

very helpful thank youPost in thread 'HDS Systems EDC # 19'

https://www.candlepowerforums.com/threads/hds-systems-edc-19.417896/post-5096411

Henry said:if you change the spectral content, you directly affect the accuracy of the reading

thanks, that really helps me get a better idea why all the Novatacs Ive measured read low.. by a LOT

I calibrated my meter to a 2011 HDS w XP-G CW 200 lumens

The Novatacs use a different LED, the P4.

the first Gen Novatac, w P4 LED, on my meter, reads 71 lumens

the Spa Novatac also w P4 LED, on my meter, reads 92 lumens

since the Novatac first gen was supposed to be 120 lumens, my meter reads the Gen1 Novatac P4 LED 41% too low

Im happy to learn that my Spa Novatac is actually making 156 lumens.. woohoo… but, wait, 156 is only 30% brighter than the First Gen Novatac.. Henry taught us that is not a visible difference. It needs to be 50% brighter, to make a small visual step...

all that to say

making decisions based on Lumens, is fraught with errors

enjoy your lights, regardless of their lumens

Hogokansatsukan

Flashlight Enthusiast

I tend to use sarcasm... My mother tried to beat it out of me with a stone tablet a long time ago... she was unsuccessful.

I very much doubt that the NT's during the time of Spa were calibrated very well... just knowing how things were run at that time. The ones that left Tucson were calibrated and then double checked on an integrating sphere... every one of them.

While possible there is some diminished output, it wouldn't be anywhere near 41%. A really dirty lens can drop it by 10% (ask me how I know! LOL!)

When we (and by "we" I mean "me") calibrate lights at HDS, the specific emitter must be programmed into the calibrator to account for differences in spectral content, then double and triple checked on the integrating sphere to make sure the calibrator is doing what it is supposed to for the specified emitter. This has to be done every time a new emitter is offered.

I'm not that bright (around 5 lumens give or take) and what I know about this has simply been what I have learned from Henry as he has tried to beat it into me over the years.

I very much doubt that the NT's during the time of Spa were calibrated very well... just knowing how things were run at that time. The ones that left Tucson were calibrated and then double checked on an integrating sphere... every one of them.

While possible there is some diminished output, it wouldn't be anywhere near 41%. A really dirty lens can drop it by 10% (ask me how I know! LOL!)

When we (and by "we" I mean "me") calibrate lights at HDS, the specific emitter must be programmed into the calibrator to account for differences in spectral content, then double and triple checked on the integrating sphere to make sure the calibrator is doing what it is supposed to for the specified emitter. This has to be done every time a new emitter is offered.

I'm not that bright (around 5 lumens give or take) and what I know about this has simply been what I have learned from Henry as he has tried to beat it into me over the years.

Hogokansatsukan

Flashlight Enthusiast

If people are not measuring with an integrating sphere, their measurements are going to be off... it is a matter of if they CARE that those measurements are off... and we all know many companies where the lumen output is measured by the marketing department.

The integrating sphere (which brand and model) is also important. There was an instance not that long ago where someone purchased one (I am guessing from a company with... let's say "questionable" ethics.) The sphere had no way of being calibrated (not a good sign), and the readings from said sphere were published on one of our vendor's web sites... those numbers were VERY high.... once we got wind of this, we made them take those numbers down... If you don't have accurate tools to measure, your measurements are going to be off. One can't substitute a micrometer with a yard stick and call it good.

The integrating sphere (which brand and model) is also important. There was an instance not that long ago where someone purchased one (I am guessing from a company with... let's say "questionable" ethics.) The sphere had no way of being calibrated (not a good sign), and the readings from said sphere were published on one of our vendor's web sites... those numbers were VERY high.... once we got wind of this, we made them take those numbers down... If you don't have accurate tools to measure, your measurements are going to be off. One can't substitute a micrometer with a yard stick and call it good.

Last edited:

Hogokansatsukan

Flashlight Enthusiast

Here is from the FAQ on the HDS web site... pay attention to paragraph's 3-5.

What are lumens, spec sheet lumens and out-the-front lumens?

The Lumen is the international unit of luminous flux, which is a measure of the total "amount" of visible light emitted by a source. Luminous flux differs from power (radiant flux) in that luminous flux measurements reflect the varying sensitivity of the human eye to different wavelengths of light, while radiant flux measurements indicate the total power of all electromagnetic waves emitted, independent of the eye's ability to perceive it.

Your eyes are not uniformly sensitive to all colors of light. Your eyes are most sensitive to green light and least sensitive to violet and red light. The lumen takes the relative sensitivity of your eyes into consideration. The spectral content of light is multiplied by the sensitivity curve of your eye to create a final result. Thus, a milliwatt of green light (555nm) counts much higher in lumens than a milliwatt of violet light (415nm) or a milliwatt of red light (630nm).

Measuring lumens is difficult as it requires specialized equipment - namely an integrating sphere with calibrated spectrometer and special software. We start the measurement process by calibrating the spectrometer using a NIST (National Institute of Standards and Technology) traceable light source with a known spectral content. This calibration step is needed to account for measurement errors in the spectrometer. Then the light being measured must be broken up into the individual wavelengths and each wavelength must be accurately measured using the calibration data to correct any measurement errors. This results in a power spectrum. The power spectrum is then multiplied by the lumen sensitivity curve to generate a lumen spectrum. Finally, the lumen spectrum is integrated to generate a final calibrated lumen value.

A calibrated spectrometer can also be used to calculate the correlated color temperature (CCT), the color rendering index (CRI), CIE values and many other interesting numbers. We use a calibrated spectrometer for all of our LED and flashlight evaluations.

A light meter is not a calibrated spectrometer and cannot be used for accurate light measurement. A light meter is a single sensor behind a filter and can only take a single measurement. The filter and sensitivity of the sensor only roughly approximate the lumen spectral response. In fact, most light meters come with instructions on how to adjust the meter reading depending on the type of light source you have. Remember, light meters were designed for photographic and building illumination use so if you are off by half an f-stop (1.4x), it is no big deal because both film and the human eye are logarithmic.

The lumen is directly related to two other units of light measurement: lux and candela. A lux is the measure of illuminance, which means how much light is falling on a surface. The candela is the measure of luminous intensity, which means how much light is being emitted in a particular direction. These units of measure have the following relationships. A lux is one lumen spread over one square meter. A candela is one lumen spread across the solid angle of one steradian. The area at one meter distance from the point of a cone that occupies one steradian is one square meter. Thus one lumen is equal to one lux which is equal to one candela for one steradian at one meter from the source.

LEDs are tested after manufacture and sorted into bins. One of the bin categories has to do with how many lumens the LED will generate under a well defined set of conditions. For example, one manufacture places LEDs that generate from 87.4 lumens to 113.6 lumens at 350mA into their U bin and LEDs that generate from 113.6 lumens to 147.7 lumens into their V bin. The manufacturer allows a production tolerance of +/-10% for the measuring equipment. This means that the output of LEDswithin one bin can vary over a 40% range.

It is common for a flashlight manufacturer to improve their flashlight's apparent output specification by claiming that they are generating the average bin lumens stated on the LED manufacturer's specification sheet. Or they may state the output specification as "up to" the maximum bin lumens stated on the LED manufacturer's specification sheet. Both of these are deceptive practices. This is referred to as spec sheet lumens.

An example will help you understand the deception of spec sheet lumens. Suppose we have an LEDfrom a bin with a typical 40% spread - 180 lumens to 300 lumens. The average will be 240 lumens. The "up to" will be 300 lumens. And that is before we have taken losses from the optical system into consideration. In the end, you can end up with a 200 lumen flashlight being marketed as a 300 lumen flashlight. But wait, the deception gets worse.

The LED's spec sheet lumens are typically measured under ideal conditions at 25°C - before the LEDhas a chance to heat up. Once the LED operates at full power for a short period it will heat up and loose at least 20% of it's lumen output. So if the LED was from the bottom of the bin, you may find the LED is generating less than 50% of the claimed lumens under real conditions. The "up to" 300 lumens flashlight may only be generating 150 lumens - at the LED. Once you take the optical system losses into account, you may be getting 35 to 45% of the claimed lumens out the front of the flashlight. The "up to" 300 lumens flashlight may actually be emitting a mere 110 lumens out the front of the flashlight.

A better way to rate flashlights is to measure the light output after it has passed through the optical system and once the LED has had a chance to warm up. This is sometimes referred to as out-the-front (OTF) lumens. This is the method prescribed by the ANSI FL-1 standard. Unfortunately, the ANSI FL-1 standard allows you to perform the testing on 3 "representative" lights, which does not take care of the unit-to-unit variations between individual LEDs within the same bin. Two flashlights with the same lumen rating can still produce easily visible differences in output and be compliant.

HDS Systems is the only manufacturer to go the final step and calibrate each flashlight. We measure the output of each flashlight after it is completely assembled and adjust the output to produce the specified lumen output. This method allows the LED to warm up to operating temperature as part of the measurement process so the flashlight's true lumen output can be measured and adjusted under representative operating conditions. Thus, our 250 lumen flashlight can be counted on to actually produce 250 lumens.

What are lumens, spec sheet lumens and out-the-front lumens?

The Lumen is the international unit of luminous flux, which is a measure of the total "amount" of visible light emitted by a source. Luminous flux differs from power (radiant flux) in that luminous flux measurements reflect the varying sensitivity of the human eye to different wavelengths of light, while radiant flux measurements indicate the total power of all electromagnetic waves emitted, independent of the eye's ability to perceive it.

Your eyes are not uniformly sensitive to all colors of light. Your eyes are most sensitive to green light and least sensitive to violet and red light. The lumen takes the relative sensitivity of your eyes into consideration. The spectral content of light is multiplied by the sensitivity curve of your eye to create a final result. Thus, a milliwatt of green light (555nm) counts much higher in lumens than a milliwatt of violet light (415nm) or a milliwatt of red light (630nm).

Measuring lumens is difficult as it requires specialized equipment - namely an integrating sphere with calibrated spectrometer and special software. We start the measurement process by calibrating the spectrometer using a NIST (National Institute of Standards and Technology) traceable light source with a known spectral content. This calibration step is needed to account for measurement errors in the spectrometer. Then the light being measured must be broken up into the individual wavelengths and each wavelength must be accurately measured using the calibration data to correct any measurement errors. This results in a power spectrum. The power spectrum is then multiplied by the lumen sensitivity curve to generate a lumen spectrum. Finally, the lumen spectrum is integrated to generate a final calibrated lumen value.

A calibrated spectrometer can also be used to calculate the correlated color temperature (CCT), the color rendering index (CRI), CIE values and many other interesting numbers. We use a calibrated spectrometer for all of our LED and flashlight evaluations.

A light meter is not a calibrated spectrometer and cannot be used for accurate light measurement. A light meter is a single sensor behind a filter and can only take a single measurement. The filter and sensitivity of the sensor only roughly approximate the lumen spectral response. In fact, most light meters come with instructions on how to adjust the meter reading depending on the type of light source you have. Remember, light meters were designed for photographic and building illumination use so if you are off by half an f-stop (1.4x), it is no big deal because both film and the human eye are logarithmic.

The lumen is directly related to two other units of light measurement: lux and candela. A lux is the measure of illuminance, which means how much light is falling on a surface. The candela is the measure of luminous intensity, which means how much light is being emitted in a particular direction. These units of measure have the following relationships. A lux is one lumen spread over one square meter. A candela is one lumen spread across the solid angle of one steradian. The area at one meter distance from the point of a cone that occupies one steradian is one square meter. Thus one lumen is equal to one lux which is equal to one candela for one steradian at one meter from the source.

LEDs are tested after manufacture and sorted into bins. One of the bin categories has to do with how many lumens the LED will generate under a well defined set of conditions. For example, one manufacture places LEDs that generate from 87.4 lumens to 113.6 lumens at 350mA into their U bin and LEDs that generate from 113.6 lumens to 147.7 lumens into their V bin. The manufacturer allows a production tolerance of +/-10% for the measuring equipment. This means that the output of LEDswithin one bin can vary over a 40% range.

It is common for a flashlight manufacturer to improve their flashlight's apparent output specification by claiming that they are generating the average bin lumens stated on the LED manufacturer's specification sheet. Or they may state the output specification as "up to" the maximum bin lumens stated on the LED manufacturer's specification sheet. Both of these are deceptive practices. This is referred to as spec sheet lumens.

An example will help you understand the deception of spec sheet lumens. Suppose we have an LEDfrom a bin with a typical 40% spread - 180 lumens to 300 lumens. The average will be 240 lumens. The "up to" will be 300 lumens. And that is before we have taken losses from the optical system into consideration. In the end, you can end up with a 200 lumen flashlight being marketed as a 300 lumen flashlight. But wait, the deception gets worse.

The LED's spec sheet lumens are typically measured under ideal conditions at 25°C - before the LEDhas a chance to heat up. Once the LED operates at full power for a short period it will heat up and loose at least 20% of it's lumen output. So if the LED was from the bottom of the bin, you may find the LED is generating less than 50% of the claimed lumens under real conditions. The "up to" 300 lumens flashlight may only be generating 150 lumens - at the LED. Once you take the optical system losses into account, you may be getting 35 to 45% of the claimed lumens out the front of the flashlight. The "up to" 300 lumens flashlight may actually be emitting a mere 110 lumens out the front of the flashlight.

A better way to rate flashlights is to measure the light output after it has passed through the optical system and once the LED has had a chance to warm up. This is sometimes referred to as out-the-front (OTF) lumens. This is the method prescribed by the ANSI FL-1 standard. Unfortunately, the ANSI FL-1 standard allows you to perform the testing on 3 "representative" lights, which does not take care of the unit-to-unit variations between individual LEDs within the same bin. Two flashlights with the same lumen rating can still produce easily visible differences in output and be compliant.

HDS Systems is the only manufacturer to go the final step and calibrate each flashlight. We measure the output of each flashlight after it is completely assembled and adjust the output to produce the specified lumen output. This method allows the LED to warm up to operating temperature as part of the measurement process so the flashlight's true lumen output can be measured and adjusted under representative operating conditions. Thus, our 250 lumen flashlight can be counted on to actually produce 250 lumens.

jon_slider

Flashlight Enthusiast

- Joined

- Mar 31, 2015

- Messages

- 5,150

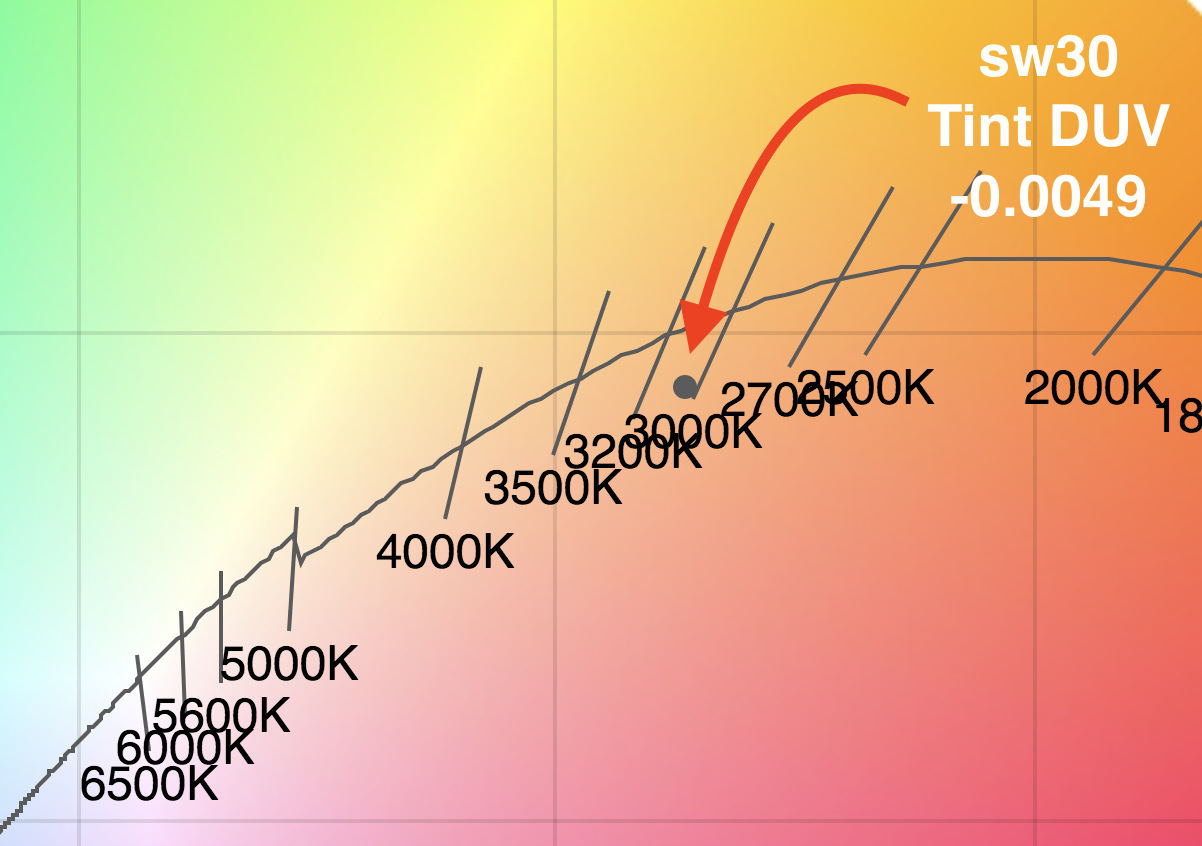

Novatac Spa

modded to sw30

max was 92 lumens stock

now 190 lumens w sw30

Im really happy with the beam. the LED Tint and CCT, the output boost, and the High CRI upgrade.

modded to sw30

max was 92 lumens stock

now 190 lumens w sw30

Im really happy with the beam. the LED Tint and CCT, the output boost, and the High CRI upgrade.

knucklegary

Flashlight Enthusiast

Nice refresh!

jon_slider

Flashlight Enthusiast

- Joined

- Mar 31, 2015

- Messages

- 5,150

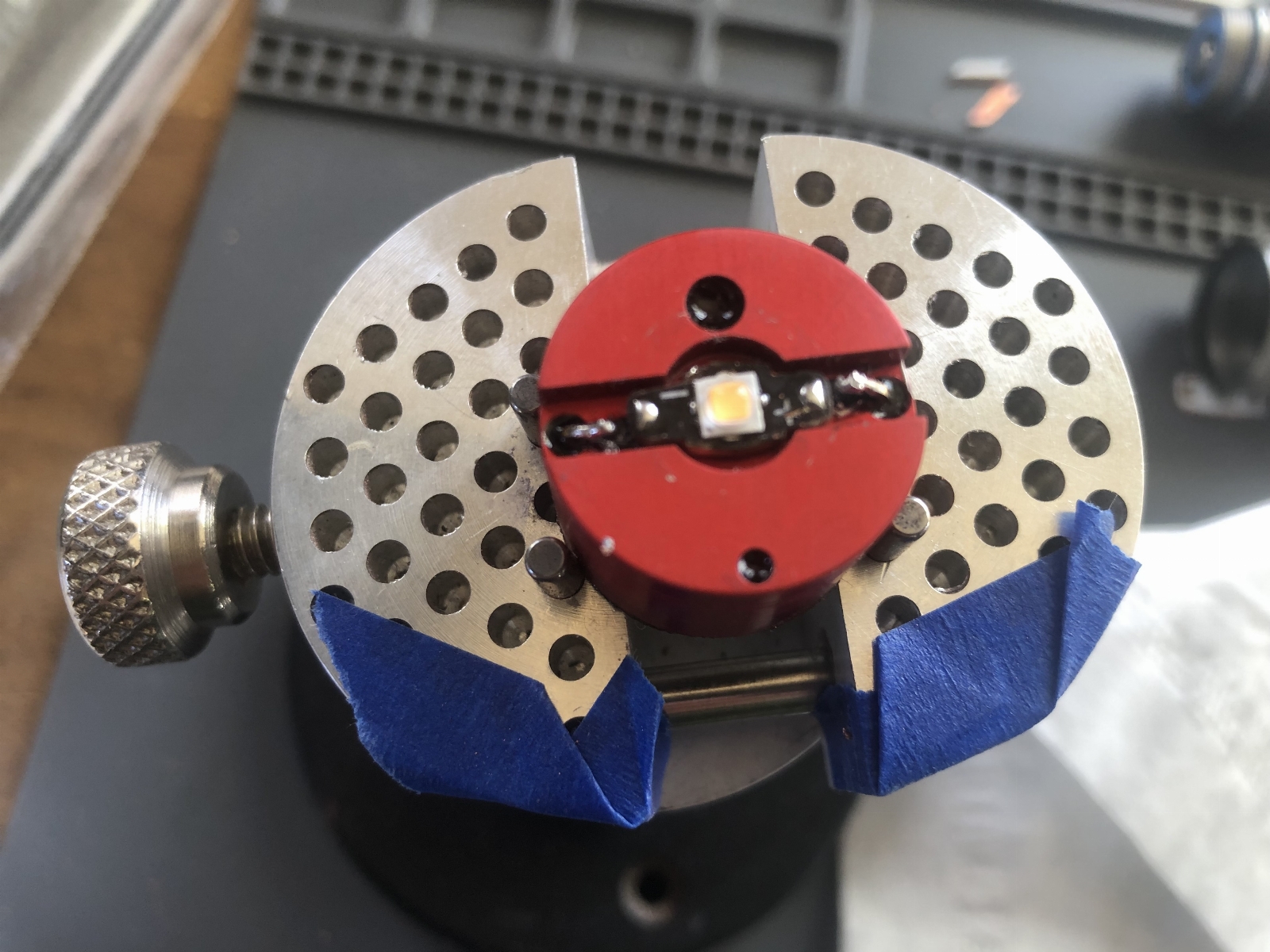

Novatac Gen 1 mod to 219b 3000k 9080

was low of 0.1, max of 60 lumens on my meter

stock 6000k Low CRI

.

.

.

.

now low of 0.1, max of 235 lumens

used a dremel to grind down a 12mm mcpcb

.

.

mounted the mcpcb w thermal epoxy and added Kapton tape over the solder joints.. after a lot of fiddling, got the LED centered.. quite happy.

3000k High CRI Nichia 219b:

.

.

I note the sw30 likes to turn extra pink after a few seconds at max output, so I programmed the ceiling to 140 lumens, to prevent that …

was low of 0.1, max of 60 lumens on my meter

stock 6000k Low CRI

now low of 0.1, max of 235 lumens

used a dremel to grind down a 12mm mcpcb

mounted the mcpcb w thermal epoxy and added Kapton tape over the solder joints.. after a lot of fiddling, got the LED centered.. quite happy.

3000k High CRI Nichia 219b:

I note the sw30 likes to turn extra pink after a few seconds at max output, so I programmed the ceiling to 140 lumens, to prevent that …

Last edited:

Hogokansatsukan

Flashlight Enthusiast

Did you put some thermal paste under the emitter? The LED heating up could cause the pink issue. The golden dragons turned blue when too hot... pink may be the preferred color on the SW30...I note the sw30 likes to turn extra pink after a few seconds at max output, so I programmed the ceiling to 140 lumens, to prevent that …

jon_slider

Flashlight Enthusiast

- Joined

- Mar 31, 2015

- Messages

- 5,150

I think the pink is from too much Powah!

both Novatacs Ive modded to sw30 behave the same way on maximum.

On the first one I tried thermal paste under the LED and also between the pill and body. I also tried thermal tape. Since the Pink Persisted...

On the Gen 1, I used Thermal Epoxy. It made no difference or I would redo the other light to match.

The thermal epoxy is a first for me.. I like it.. as it creates a very close bond to the mcpcb and will hold centering securely (if I do my job and get the LED centered before the epoxy sets up)

On maximum of 190 lumens and 235 lumens, both lights become increasingly pink within the first 10 seconds.. that does not happen at 140 lumens.

I could try a different LED.. to see if the Powah! limit is inherent to the warmer LED...

or maybe the issue is that the mcpcb got ground down to such a small size, that the copper that is left cant keep up moving heat off the LED fast enough.. even when embedded in thermal epoxy..

the light feels only slightly warm, not hot, when the tint starts getting pinker..

both Novatacs Ive modded to sw30 behave the same way on maximum.

On the first one I tried thermal paste under the LED and also between the pill and body. I also tried thermal tape. Since the Pink Persisted...

On the Gen 1, I used Thermal Epoxy. It made no difference or I would redo the other light to match.

The thermal epoxy is a first for me.. I like it.. as it creates a very close bond to the mcpcb and will hold centering securely (if I do my job and get the LED centered before the epoxy sets up)

On maximum of 190 lumens and 235 lumens, both lights become increasingly pink within the first 10 seconds.. that does not happen at 140 lumens.

I could try a different LED.. to see if the Powah! limit is inherent to the warmer LED...

or maybe the issue is that the mcpcb got ground down to such a small size, that the copper that is left cant keep up moving heat off the LED fast enough.. even when embedded in thermal epoxy..

the light feels only slightly warm, not hot, when the tint starts getting pinker..

Last edited:

Hogokansatsukan

Flashlight Enthusiast

The light doesn't have to feel warm for the LED to be overheating... this was a big production problem at Novatac during initial production. We would test each light for 5 minutes on an integrating sphere to make sure lumen output didn't drop and there wasn't a color shift, which would turn very blue if the emitter was overheating. Was usually caused by the emitter not being flush to the pill with a good amount of thermal paste under it.

jon_slider

Flashlight Enthusiast

- Joined

- Mar 31, 2015

- Messages

- 5,150

Thank you.

I agree the LED is overheating on Maximum.. long before any heat reaches my hand.

because the new mcpcb sits lower than stock, I did not want to use a thick a layer of thermal paste

so I switched to thermal epoxy instead

the arctic silver thermal epoxy is fully bonded to the pill and mcpcb, but seems unable to cope.

for now I will limit output to 140 lumens.. more than enough for indoor distances..

will give some though to a copper shim under the mcpcb, to reduce the thickness of the thermal epoxy. (or thermal paste)

I agree the LED is overheating on Maximum.. long before any heat reaches my hand.

because the new mcpcb sits lower than stock, I did not want to use a thick a layer of thermal paste

so I switched to thermal epoxy instead

the arctic silver thermal epoxy is fully bonded to the pill and mcpcb, but seems unable to cope.

for now I will limit output to 140 lumens.. more than enough for indoor distances..

will give some though to a copper shim under the mcpcb, to reduce the thickness of the thermal epoxy. (or thermal paste)

It is better not to use a thick layer of thermal paste, if the distance is not enough, you can take a piece of another mcpcb, strip it so that only copper remains, solder to the bottom of your mcpcb with a diode and then remove excess metal on a hand grinding stone / sanding paper to achieve the desired thickness. You can also use alkali to remove the anodization from the pill under the diode, it also improves thermal conductivity, but you have to be very careful not to get it inside the pill.

jon_slider

Flashlight Enthusiast

- Joined

- Mar 31, 2015

- Messages

- 5,150

thank you!

I do have a spare mcpcb that I could unmask and grind to shape

also thanks for commenting about removing anodisation.. both very helpful suggestions

I woke up happy to have the limited output of 140 lumens max.. I rationalize it is more than the stock 120 lumen specs for a Novatac.

I actually seldom need more than 100 lumens.

Im very pleased with the Tint and Beam. And I find thermal epoxy very convenient for lifting the mcpcb, for now. Will share if I dive in to rework the lights..

happy holy days

and welcome back Hogo

glad you survived catching that Case of Corona

I do have a spare mcpcb that I could unmask and grind to shape

also thanks for commenting about removing anodisation.. both very helpful suggestions

I woke up happy to have the limited output of 140 lumens max.. I rationalize it is more than the stock 120 lumen specs for a Novatac.

I actually seldom need more than 100 lumens.

Im very pleased with the Tint and Beam. And I find thermal epoxy very convenient for lifting the mcpcb, for now. Will share if I dive in to rework the lights..

happy holy days

and welcome back Hogo

glad you survived catching that Case of Corona

HesNot

Enlightened

Fun walk down semi memory lane. I had an Arc4+, then an HDS B42, then an HDS P80 and finally a Novatac 120P. I still have the 120P and use it pretty regularly still - works great - it does have a tritium bezel (one tube has finally given up after all these years...) and was modded not too long after I got it with a luxeon K2 emitter. I have upgraded it since as the tint and lumen output is just fine for my needs as is. I seem to recall when the mod was done it was anticipated that high would go from 120 to maybe 160/180. More most applications this is still sufficient. I've used this regularly - sometimes as an EDC sometimes as a bedside light - for tasks and jobs around the house (and under it!) - so the HAIII has worn some but it's been amazingly robust. Only dropped once and it survived with just a nick or two after contact with concrete in my garage. On low it runs forever (and longer on locator beacon as we know  ) so it's always charged when bad weather is threatening - hurricanes and ice mostly here. Don't know that I have had a better light. One day I'll get a new rotary to stand beside it.

) so it's always charged when bad weather is threatening - hurricanes and ice mostly here. Don't know that I have had a better light. One day I'll get a new rotary to stand beside it.

jon_slider

Flashlight Enthusiast

- Joined

- Mar 31, 2015

- Messages

- 5,150

nice one.. similar First Gen serial number as this one I got recently, and modded to 3000k 219b:Fun walk down semi memory lane.

View attachment 23725

HesNot

Enlightened

nice one.. similar First Gen serial number as this one I got recently, and modded to 3000k 219b:

View attachment 23729

They look very similar indeed! Nice work on the mod!

jon_slider

Flashlight Enthusiast

- Joined

- Mar 31, 2015

- Messages

- 5,150

thanks.. it is a 120T, raised button instead of flush.. I changed the output presets to match a 120P

I like the flush button on your 120P, so I copied you:

so much more useful to be able to tailstand ;-)

I like the flush button on your 120P, so I copied you:

so much more useful to be able to tailstand ;-)

Last edited:

jon_slider

Flashlight Enthusiast

- Joined

- Mar 31, 2015

- Messages

- 5,150

Happy Holidays! ;-)

Stock 6000K, mod to 219b 3000K

Stock 6000K, mod to 219b 3000K

Last edited:

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 105

- Views

- 24K