GlazedDonut

Newly Enlightened

- Joined

- Sep 2, 2010

- Messages

- 2

Working on my first DIY light. I't's a can-light with a modified mag-lite head and a single-mode LED module.

Bear with me here, because I'm a complete ignoramus with electrical stuff. I know enough to hook up a toggle switch with a boot, but from everything I've read, this option is the most prone to leakage. I'd also like to mount the switch to the light-head instead of the canister. It sounds like a Piezo switch is the way to go for maximum durability, so a couple of bonehead questions before I spend the money:

1. I may not be clear about how a Piezo switch works, but I'm understanding that it's pressure-actuated, which begs the question...why won't it become actuated with increasing water pressure as I descend?

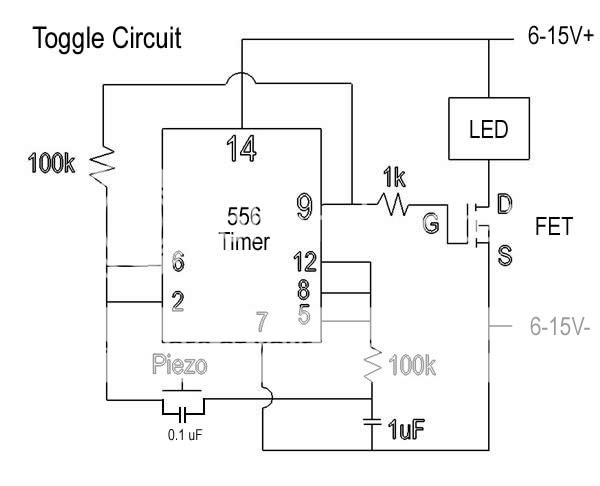

2. I understand that a Piezo acts as a momentary contact switch, which needs additional "latching" circuitry to operate as an on/off toggle. I'm not smart enough to build something like that, but I found this product on another thread: http://www.pololu.com/catalog/product/750

If I replace the switch on this board with a Piezo, wouldn't this give me an on/off switch? If not, is it possible to find an on/off piezo switch, or a pre-fab circuit that a dummy like me can install a piezo switch to?

Bear with me here, because I'm a complete ignoramus with electrical stuff. I know enough to hook up a toggle switch with a boot, but from everything I've read, this option is the most prone to leakage. I'd also like to mount the switch to the light-head instead of the canister. It sounds like a Piezo switch is the way to go for maximum durability, so a couple of bonehead questions before I spend the money:

1. I may not be clear about how a Piezo switch works, but I'm understanding that it's pressure-actuated, which begs the question...why won't it become actuated with increasing water pressure as I descend?

2. I understand that a Piezo acts as a momentary contact switch, which needs additional "latching" circuitry to operate as an on/off toggle. I'm not smart enough to build something like that, but I found this product on another thread: http://www.pololu.com/catalog/product/750

If I replace the switch on this board with a Piezo, wouldn't this give me an on/off switch? If not, is it possible to find an on/off piezo switch, or a pre-fab circuit that a dummy like me can install a piezo switch to?