Mattaus

Flashlight Enthusiast

Seems like this AlTiN stuff is popular...might have to look into it more.

You can become a Supporting Member.

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

I would find a way to buy another Haiku and have it AlTiN coated if someone could do it for a reasonable price (i.e. a bunch of us share the cost of the service)

Hi guys,

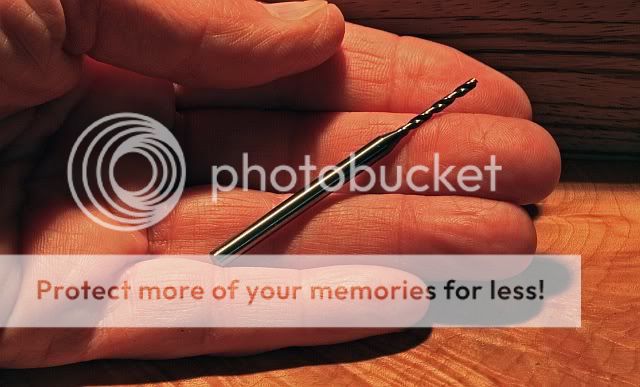

I added an edit to the first post in this thread regarding the necessary tool for installation and removal of the clip screws. This subject has come up numerous times over the years but the various discussions are now buried in old threads. I install the clip screws with the sole intent that they remain in place and I use a very good driver that produces significant torque for snugging the screws in place. Consequently you need a good driver to remove the screws!

I spoke with a salesperson at MIP where the Thorpe driver is made and she told me I would be able to buy some drivers directly from her but I have not heard back from her after sending her my contact information via e-mail. You can find any number of Hobby Supplies on line who offer the MIP Thorpe 1/16" driver but I realize that for some of you international members or folks not living in the states that the shipping can be excessive (it is for me here in Hawaii). If I am successful in obtaining a number of these drivers I will post so in this thread and hopefully be able to offer a driver at the going on-line price but with the advantage of including it with a light and avoiding additional shipping fees.

A couple of overseas companies are "borrowing" your clip design, but the quality is pretty bad. They look the same at first glance but are about half as thin and have little grip on a pocket. I'm curious if you designed that clip style Don, or someone of your team? It works, & looks good doing it! Why oh why is it so hard for anyone else to do properly?

Hi guys,

I have these clips made for my flashlights. I am not focused on components for other flashlights or exotic materials for cosmetic purposes.