Hi Steve,

Many thanks for your excellent work and for sharing, it has been a great help

no problem. Feedback like yours helps justify my urge to document projects like this.

....The bit I'm currently stuck on is figuring out if and how I can get the tail light (USB) to carry on charging even when the front light is switched off? Ideally, my hope is to use the switch on the E3 to toggle between front light and USB charging and if I then remove the load from the USB charging wires (tail light) by disconnecting the powerpack I efectively turn it off to reduce dynamo resistance? I hope that makes sense?

May I ask if you think this idea might work?

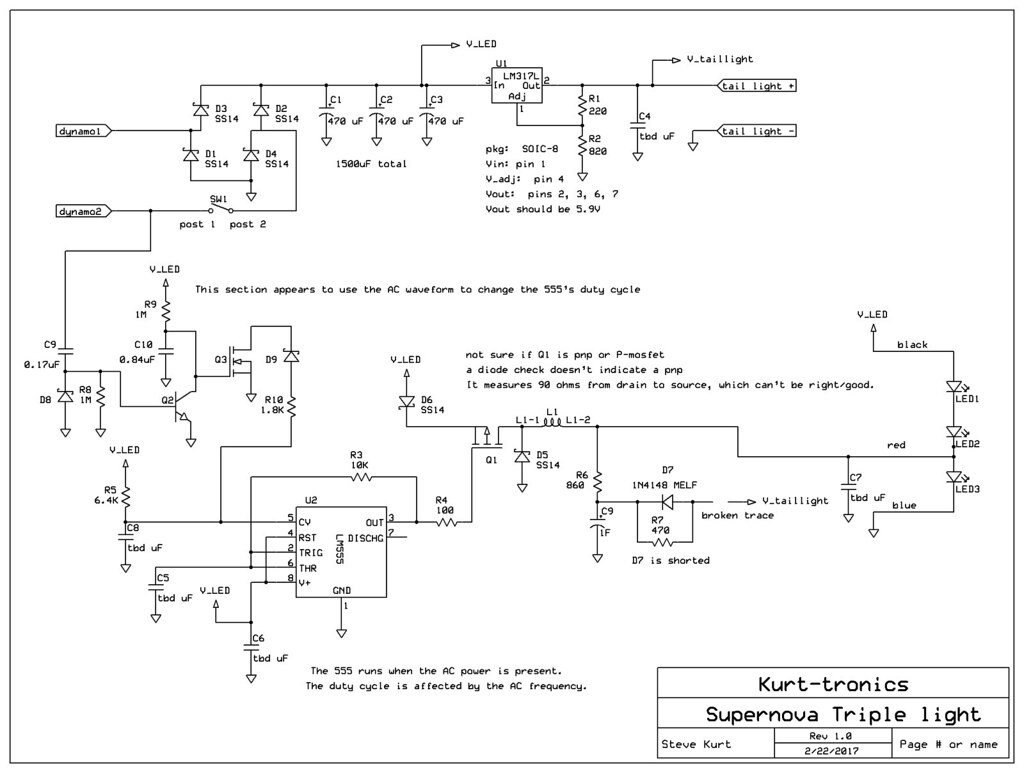

One thing that I enjoy about the design of the Supernova is that they use the LEDs as a way to clamp (i.e. limit) the voltage out of the dynamo. The high source impedance of the dynamo lends itself to this sort of shunt regulation.

Unfortunately, if you aren't using the LEDs to load the dynamo, then you can see some very high voltages out of the dynamo. This problem increases as the current drawn from the dynamo decreases.

If you were to feed the output of the full wave rectifier to the LM317, there would be a voltage where the LM317 would be damaged. Looking at the datasheet, it says that the absolute max voltage between input and output is 40V. With a 5.2V output, that means that anything over 45.2V out of the rectifier could damage the LM317.

My recent measurements of my 1st generation SON dynamo showed that with no load, I would get 29VAC at 20mph. This is about 40V peak, so anything over 20mph is getting close to potentially damaging a LM317, and as a result, possibly the device being charged via the USB connection.

One option would be to design a high voltage series regulator. Another option would be to use a shunt regulator to get the desired 5.2V. It'll still use up to 2.5W or so, but that's less than the power used by the Supernova when it is on.

Another option would be a switching regulator (buck converter) designed to operate with high input voltages. This could provide more current for charging the powerpack than a linear regulator such as the LM317. There are ones designed to be used in automotive applications that can handle 60 to 80V (IIRC), and might be a good solution. My instinct would be to buy the parts and design and build one myself, but I'm going to guess that someone sells these on ebay. Not sure if you can trust their design or not, though.

Have you considered the assorted issues associated with charging lithium batteries? There are limits regarding temperature, state of charge of the battery, etc. .... or does the powerpack take care of that? I'll guess that it does.

Well, those are some ideas. There are pro's and con's to each of them.

Another idea would be to buy a commercially built device such as the Sinewave. No personal experience with the device, but I've heard good things about it.