wquiles

Flashaholic

I am having a few challenges drilling into Titanium and with my Dorian cut knurler, so Barry recommended I try flood coolant instead of my near-dry cooling system. So of course, I followed his advice

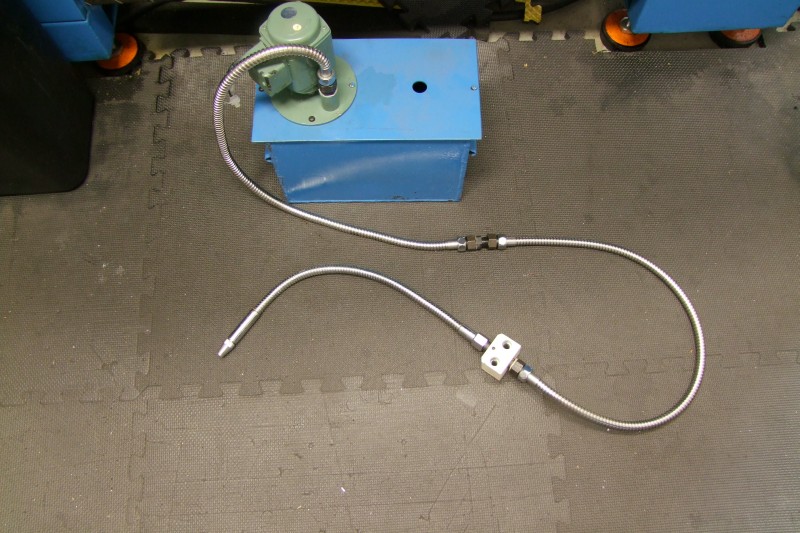

The original cooling system that came with the lathe was of extremely low quality. But, I decided to try use the hoses, at least to get started:

A neat thing about the factory "tank" is the hole with the mesh filter. It allows fluid to go from one side to the other, but the debris stay at the bottom, and don't make it to the side of the pump:

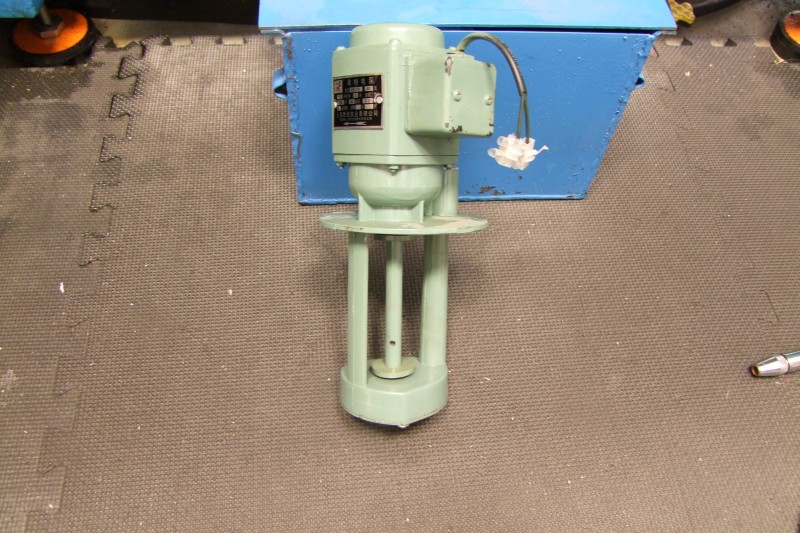

Per Barry's recommendation I bought this pump. It is excellent, and quiet!:

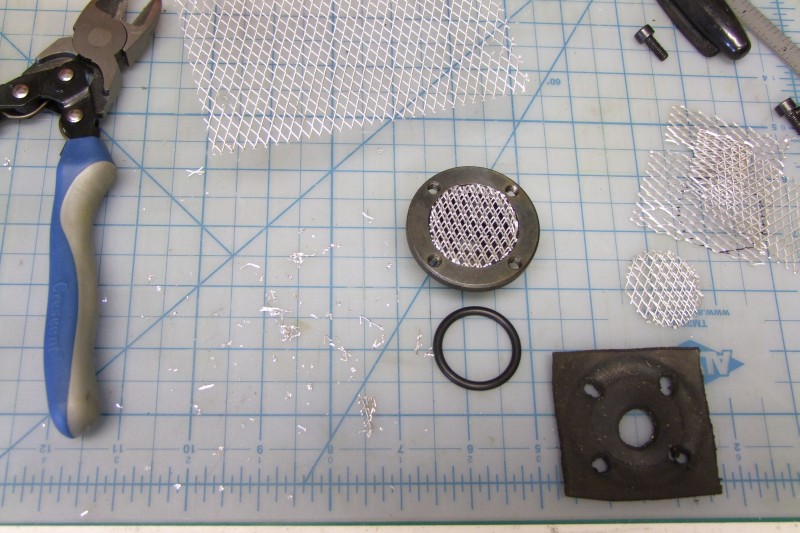

The factory "filter" on the chip pan had this really fragile screen:

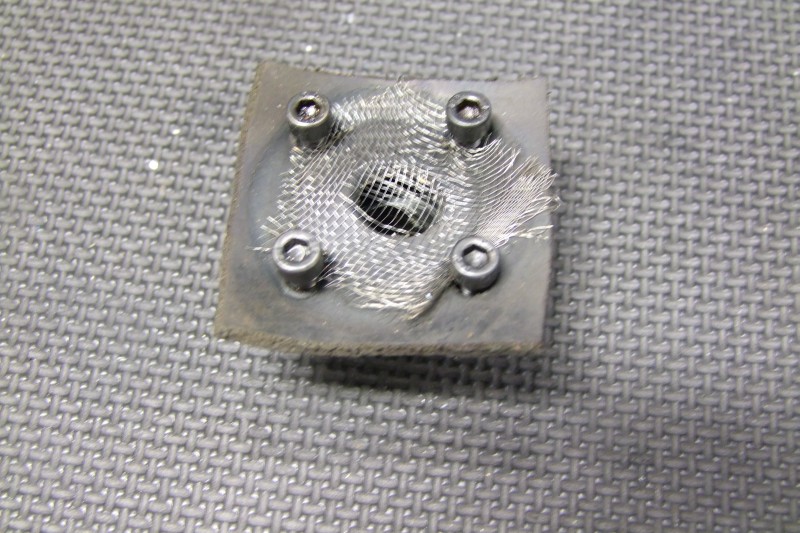

So I decided to make something a little bit stronger and ticker, and used silicone sealant for it:

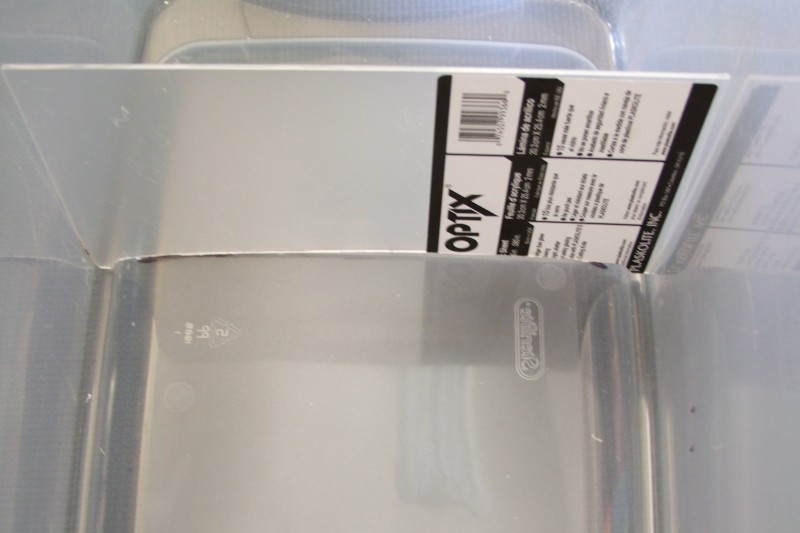

For the tank, I used a plastic container from my local Target, and a plexiglass piece to act as dividing wall:

I drilled a lot of small holes to allow fluid to cross over, while letting debris stay on the bottom. Then used silicon sealant again:

Here I am testing it - worked great:

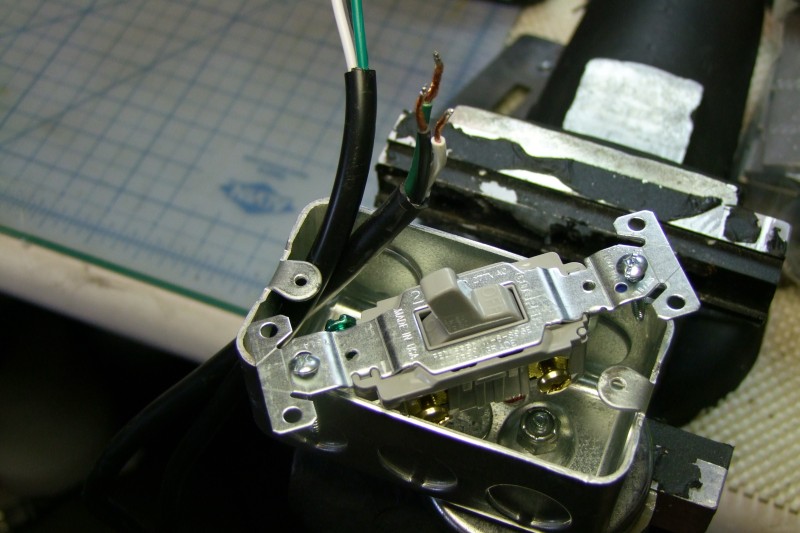

For the switch, I am using a SPST on a metal case with a magnet on the back):

I then cleaned and de-greased both contact areas, and once again, used silicone sealant. Not pretty, but it works great (zero leaks!):

It is definitely more messy compared to the near-dry lubrication system, but it works great on the cut knurler, and then drilling Ti:

Will

The original cooling system that came with the lathe was of extremely low quality. But, I decided to try use the hoses, at least to get started:

A neat thing about the factory "tank" is the hole with the mesh filter. It allows fluid to go from one side to the other, but the debris stay at the bottom, and don't make it to the side of the pump:

Per Barry's recommendation I bought this pump. It is excellent, and quiet!:

The factory "filter" on the chip pan had this really fragile screen:

So I decided to make something a little bit stronger and ticker, and used silicone sealant for it:

For the tank, I used a plastic container from my local Target, and a plexiglass piece to act as dividing wall:

I drilled a lot of small holes to allow fluid to cross over, while letting debris stay on the bottom. Then used silicon sealant again:

Here I am testing it - worked great:

For the switch, I am using a SPST on a metal case with a magnet on the back):

I then cleaned and de-greased both contact areas, and once again, used silicone sealant. Not pretty, but it works great (zero leaks!):

It is definitely more messy compared to the near-dry lubrication system, but it works great on the cut knurler, and then drilling Ti:

Will