Morepower!

Enlightened

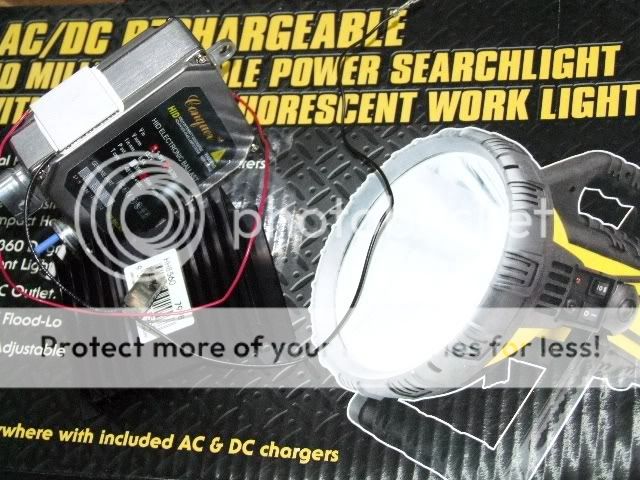

Tweeking a "55W" Kit Ballast to get an extra 18W-102W @ Bulb

After trying many different things to get more power from these "55W" automotive kits I found a very simple Mod that will net an extra 8.8W(15.09W with 1.19K resistor) @ the bulb. I can't beleive the hours I've spent soldering resistors here and there, then testing and re-testing when all I had to do was turn up the pot !!!! I played with the pot a while ago, before setting up the test equipment, but couldn't see a difference and just dismissed it. Anyway 1/4 turn clockwise is all it takes, but don't go any further than that or you will start going backwards as the pot dosn't seem to have a definate stop.

New test results so far:

Just pot mod.

0.58A AC @ Bulb

88.1V AC @ Bulb

= 51.09W

Updated results:

With 1.19K Ohm resistor

0.64A AC @ Bulb

89.6V AC @ Bulb

= 57.34W

Original test results HERE

.

After trying many different things to get more power from these "55W" automotive kits I found a very simple Mod that will net an extra 8.8W(15.09W with 1.19K resistor) @ the bulb. I can't beleive the hours I've spent soldering resistors here and there, then testing and re-testing when all I had to do was turn up the pot !!!! I played with the pot a while ago, before setting up the test equipment, but couldn't see a difference and just dismissed it. Anyway 1/4 turn clockwise is all it takes, but don't go any further than that or you will start going backwards as the pot dosn't seem to have a definate stop.

New test results so far:

Just pot mod.

0.58A AC @ Bulb

88.1V AC @ Bulb

= 51.09W

Updated results:

With 1.19K Ohm resistor

0.64A AC @ Bulb

89.6V AC @ Bulb

= 57.34W

Original test results HERE

.

Last edited: