BlackAndChrome

Newly Enlightened

- Joined

- Jun 29, 2010

- Messages

- 19

I've decided to build a dive light that I plan on using this summer when snorkeling on vacation. I've already done a few XR-E and XP-G mag mods including the heatsinks so I figured it would be interesting to take it to the next level. Especially since I have a good reason to throw some money at it.

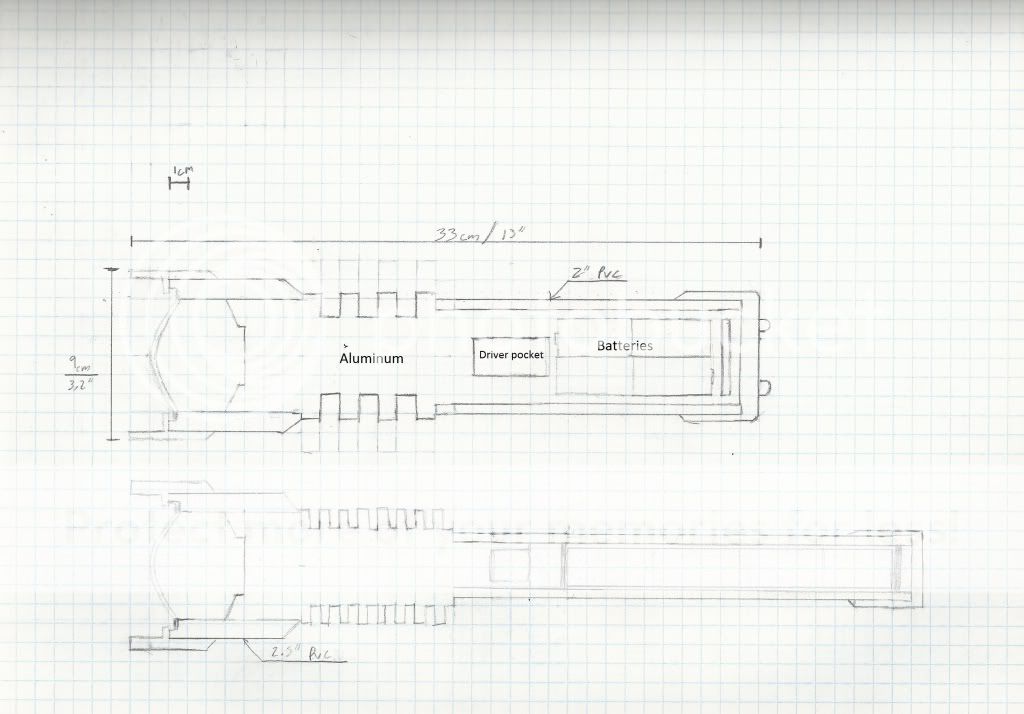

Here's the basic thought.

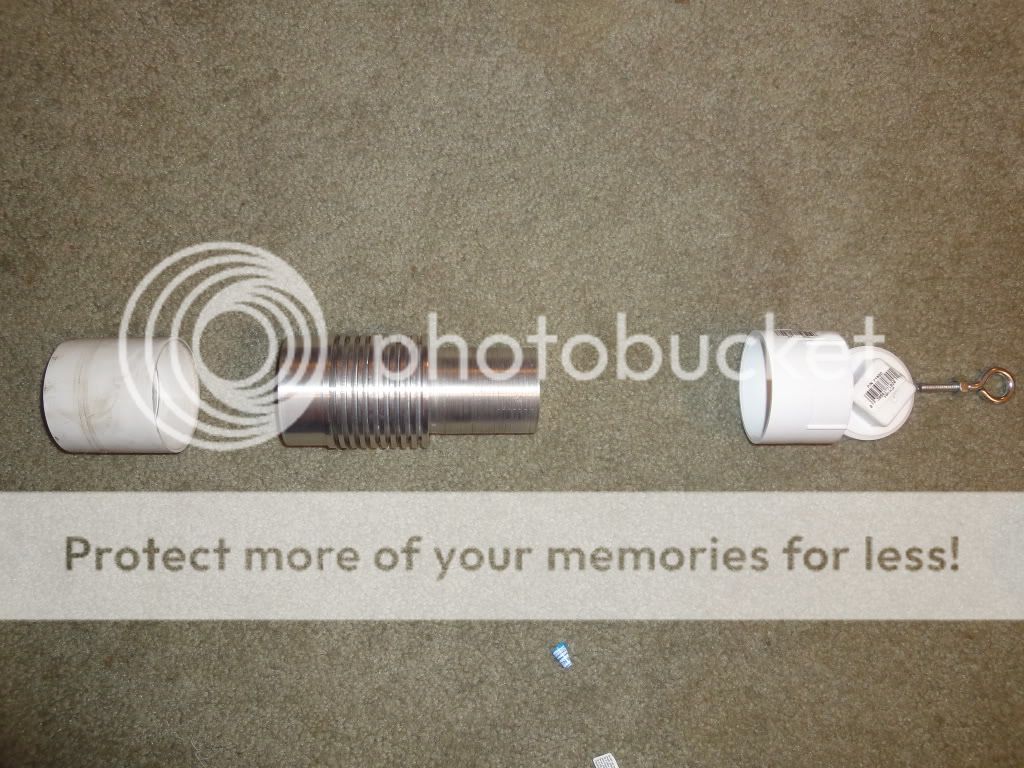

Light engine is a Cree XM-L with 3 single mode 1050mA drivers I may add another AMC 7135 to one of the drivers to drive it at 3.5A. No reflector and a DealExtreme 66mm aspheric lens. Batteries are 4xELITE 5000mAh NIMH Sub-Cs.

All of the above components have been ordered so I'm not just speculating

Now what would be the best way to switch this? I was thinking reed switches and power mosfets representing 3 different modes. The first reed switch would control a power mosfet connected to one driver while another reed switch and mosfet would turn on the other 2 drivers. Therefore the twist ring would have 2 magnets on it that line up with each reed switch. One magnet on on reed switch would give 1/3 power, one magnet on the other would give 2/3 power and both lined up would give 100%

General question, what would be the best way to seal the PVC to the Aluminum main body and the lens to the PVC? I was thinking about making grooves on the lathe and using casting epoxy but I had concerns about thermal fractures considering the likely difference in expansion rates between aluminum and PVC. PVC to PVC will obviously be purple primer and cement.

Thanks in advance for your responses to my long winded explanation I may have to engrave some CPF member names on the side of it when I am done :wave:

I may have to engrave some CPF member names on the side of it when I am done :wave:

Thanks,

-Nick

Here's the basic thought.

Light engine is a Cree XM-L with 3 single mode 1050mA drivers I may add another AMC 7135 to one of the drivers to drive it at 3.5A. No reflector and a DealExtreme 66mm aspheric lens. Batteries are 4xELITE 5000mAh NIMH Sub-Cs.

All of the above components have been ordered so I'm not just speculating

Now what would be the best way to switch this? I was thinking reed switches and power mosfets representing 3 different modes. The first reed switch would control a power mosfet connected to one driver while another reed switch and mosfet would turn on the other 2 drivers. Therefore the twist ring would have 2 magnets on it that line up with each reed switch. One magnet on on reed switch would give 1/3 power, one magnet on the other would give 2/3 power and both lined up would give 100%

General question, what would be the best way to seal the PVC to the Aluminum main body and the lens to the PVC? I was thinking about making grooves on the lathe and using casting epoxy but I had concerns about thermal fractures considering the likely difference in expansion rates between aluminum and PVC. PVC to PVC will obviously be purple primer and cement.

Thanks in advance for your responses to my long winded explanation

I may have to engrave some CPF member names on the side of it when I am done :wave:

I may have to engrave some CPF member names on the side of it when I am done :wave:Thanks,

-Nick

Last edited:

.

.