Turbo DV8

Flashlight Enthusiast

Got the light, got the SSC. Now, the head appears to be two pieces, but how do I get the two pieces apart? Thanks.

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

thezman said:I had to heat mine to break the glue bond. It was the hardest Fenix I ever took apart.

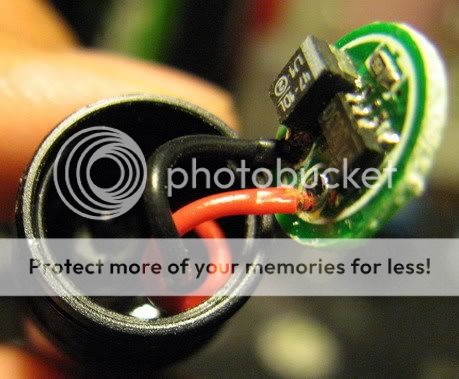

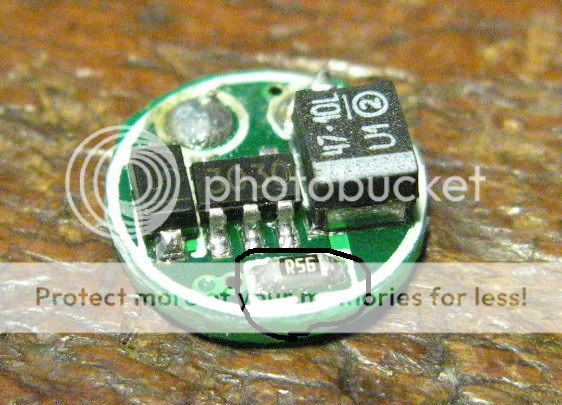

I also bypass the stock resister for get more current for emitter.

What is if hold one side form the fenix in a lathe chuck?

Zelda

Doubt he has a Lathe so check this thread for a cheaper tool to buy that will take the heat and grip to get that stubborn little sucker open.

https://www.candlepowerforums.com/threads/146949

So would you put that Bionic Wrench over the knurled head, or the smooth section just below the head? What would I hold the other half with? Or would I need two wrenches? What did you use to prevent scratching?

Click in the link I posted earlier and look at post #17. The light is an Lop not an E1 but they look basically the same.

Thanks. Is your wrench the 6", 8" or 10" version, and what is it's maximum working diameter? They list metric sizes, but I think that applies to the size of a nut. That is, a 10mm nut, but the maximum diameter of that nut will be greater than 10mm. So I need to know which size wrench you have and the farthest it will open, and I can go from there.

The difference between the nickel and black seems to be only aplicable to the handle material. The pawls appear to be the same silver material, so I don't think that the difference in grip is attributable to the "color" of the handle. Maybe one specimen is more tempermental than the next. There's always ways to increase friction. The 360 degree exertion of force is the secret ingredient.