...The efficiency of aluminium in instrument is around 85%, silver may be as high as 95%, while advanced dielectic coat can be 99%...

Thank you for this topic, funder.

I used to drive a Ford Model T for -all- my daily transport needs. I racked up about 25 thousand city-miles before one day the car got crashed.

Its headlights were electric, with the then-new for 1922, "H" lenses. The reflector bowls were large and silvered, and for my first year of driving, the original plating (aways thin, shame) was far less than optimal.

It was darkened by sub-plate tarnish of the copper strike coat.

That is to say, one could polish the silver bright, but it was no longer opague to the copper underneath.

I had my car's reflectors done over in a high-tech aluminizing, touted as superior to silver. It wasn't.

And because the aluminum coating, perfect-looking as it was at first,

was not proof against corrosive gases, it failed very soon.

So I had the bowls replated in pure silver. The light output improved noticeably, I think, better than the aluminum.

Plus, silver was polish-able. But, even though the nature of Ford's headlight design precludes sealing the assembly from gases and water vapor, I never needed to polish the fresh-plated reflectors. I drove the coupe for a year and half of so before the loss. This car was kept out of doors year-round in South Florida.

I guess that the low-sulfur fuels of today were a help?

Those 1915-basis headlights, represented with their 1921 "H" lenses, the first scientifically designed, focused, beam-shaped auto lamps ever.

They shone with modern bulbs, as bright as modern cars' standard low beams.

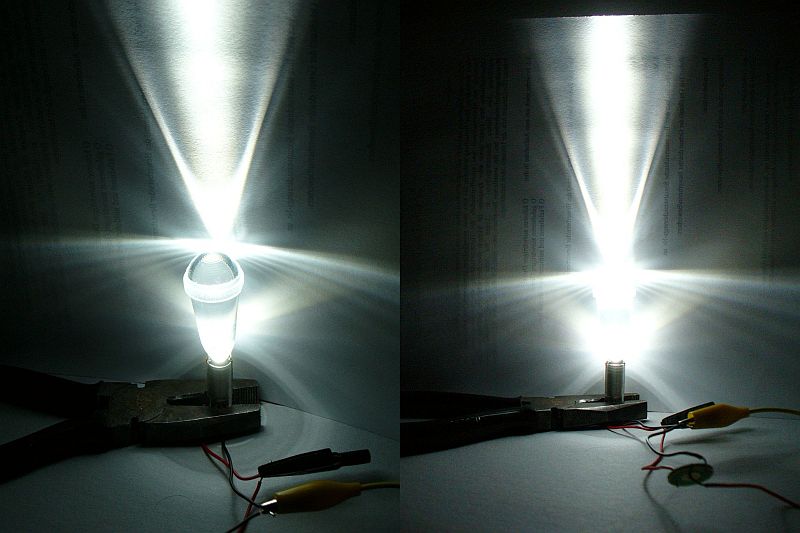

My bulbs were made by myself from -axial- filament,

mere 20W halogen bipins.

The beam pattern of the Ford H lens system was a flattened rectangle, perfectly anti-glare.

They knew their onions*, those scientists at Ford's labs.

*catchphrase of the day: "she sure knows her onions!"

Point: silver is cheap, low-tech and polish-able.

And I doubt it would necessarily tarnish for a very long while in today's quality flashlights.

It just works and it is white, and yet,

silver is not an option today? Why?