sounds like a classic over-heated LED. the heat isolation may be to blame here. Did you use thermal paste/epoxy liberally when you put the star on?

First of all - don't use thermal compound or epoxy "liberally" use as little as possible in order to just fell the fill the spaces between the star and the aluminum plate. If you apply a bunch of paste, it will act as an insulator instead of a heatsink compound. Thick amounts of compound are bad, thick amounts of epoxy/adhesive is worse.

No. I didn't use any. I screwed the star directly to an aluminum plate that transfers heat to the Mag body. I have some thermal epoxy now. When I get a new star (higher bin) I'll epoxy it to the aluminum, and epoxy the aluminum to the Mag body. I'll still be running the star at over 2A (I think. It depends on the Vf of the emitter at current/temp. and voltage drop under load with the cells)

If you can screw the star into the aluminum plate, then you don't need any type of thermal epoxy...just thermal compound. You only use epoxy/adhesive if there is a chance that he emitter/star can separate from the heatsink. Since you have screws to hold it onto the heatsink, you

should not use the epoxy. Also, if you use the epoxy between the aluminum plate and the mag body then you'll never be able to remove the heatsink plate.

You don't need

epoxy/adhesive, you just need some

heatsink compound. Arctic Silver 3, Arctic Silver 5, or Arctic Alumina. Any of those three will work fine. The difference between the heatsinking properties of the three is mere fractions of one degree Celsius. I'd use the AA or AS3 over AS5 due to cost though...the tube of AS5 is super small compared to the others...same

weight, but the AS5 is super dense compared to the AA and AS3. You said you have the epoxy now, does that mean you have Arctic Alumina adhesive/epoxy?? If so, get the AA compound...when you need to use the epoxy on something, use 75% AA epoxy and 25% AA compound. At this mixture the epoxy will still hold as long as you need, but it will also separate if you need to remove the item at a later date.

Between the star and the aluminum heatsink plate use as little as possible so it completely covers the star. Do this...squirt a little bit out, and use the tip of the heatsink compound tube to spread it around. Then put the star in place where you are going to screw it down, push down firmly. A little of the heatsink compound may come squishing out the side. Then pull the star off - check and see if there are areas of the star which did not have the compound on it. If the star has a

thin layer of compound on all surfaces, put it back down and screw it it. If you need to add a little dab more, use as little as possible to make sure the last few bits will be covered and install it. This is

not an area where

more is better! More is definitely worse in this case and will equate to a worse thermal transfer.

Then between the aluminum heatsink and the mag body - do the same with the compound...although due to the surface area and the distance from the emitter you can use a little more compound if needed. But, from the information you have said in this thread - you really don't want to use any epoxy/adhesive for this job.

I'd be worried about a lack of good heatsinking + thermal paste at 1A, let alone 2A. Even with a lot of thermal paste, I'd never try running it that hard unless the light was very well designed for dissipating heat, and I don't believe a Maglite would fall into that category.

How long were you able to use the LED before this happened?

P.S. - You mention running the LED direct-drive, the current is probably close to 1A (maybe less), not 2A.

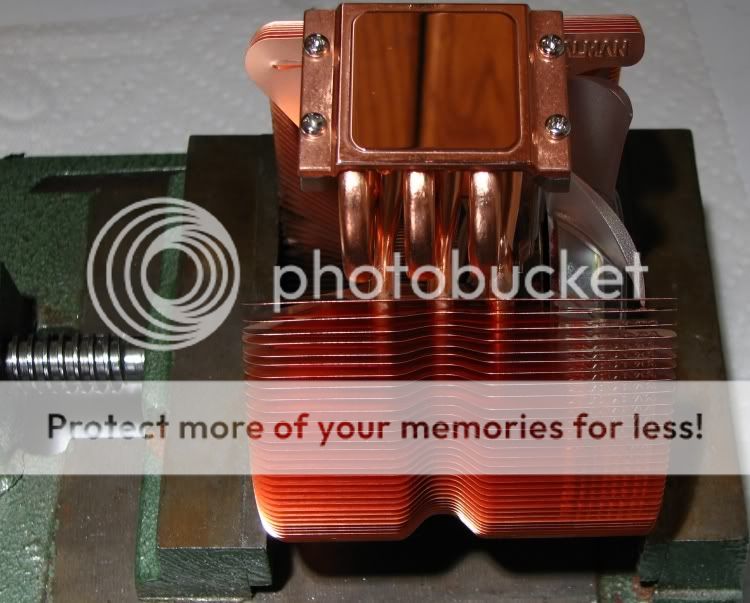

Ummm yeah, I am going to have to agree with mmmflashlights here...2A is going to kill most any emitter unless you have it hooked up to a peltier cooling device. Nobody runs a Cree at 2A...except for Newbie, but this was his heatsink:

So, a

thin layer of AA, AS3, AS5

compound between star and heatsink, thin later of AA, AS3, AS5 between the heatsink and Mag body. And find out how much current you are pulling for sure. I think the biggest problem here was bad thermal transfer between star and aluminum heatsink...although as mmmflashlights said - if you are trying to run 2A, it doesn't matter what you do to help with thermal runaway...it would be like trying to knock over a building by throwing a pebble at it.