yaesumofo

Flashlight Enthusiast

HI guys I was wondering if there is any interest in an O-Sink for the P7 emitter?

I have yet to see one in person but If there is sufficient interest I will embark on research and development program and will get some sinks made.

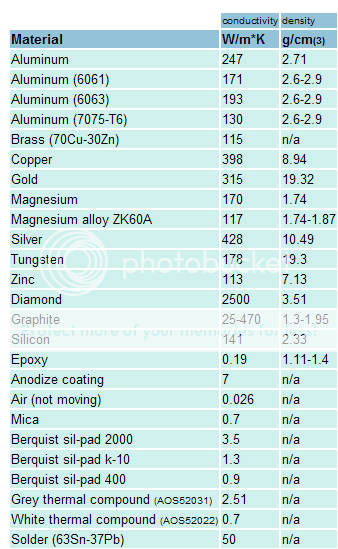

I understand the P7 runs HOT and needs great heatsinking. I could design the sink to extend deeper into the body adding mass to the sink which would be hidden inside the body of the light.... The Mag host is a natural. I don't know what the beam will look like I suspect that an aluminum reflector may be called for if the P7 is driven at it's max.

The 3 cell mad may be right for direct drive...

Ideas thoughts? welcome...

Yaesumofo

I have yet to see one in person but If there is sufficient interest I will embark on research and development program and will get some sinks made.

I understand the P7 runs HOT and needs great heatsinking. I could design the sink to extend deeper into the body adding mass to the sink which would be hidden inside the body of the light.... The Mag host is a natural. I don't know what the beam will look like I suspect that an aluminum reflector may be called for if the P7 is driven at it's max.

The 3 cell mad may be right for direct drive...

Ideas thoughts? welcome...

Yaesumofo