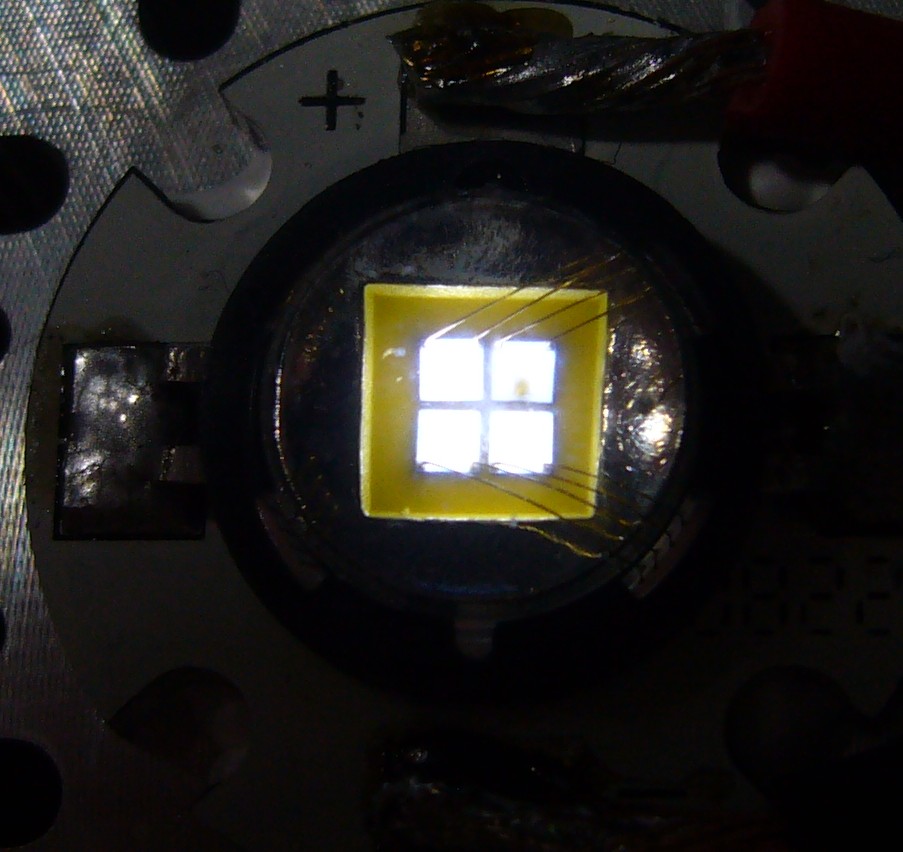

... and it was a _really_ nice daylight tint, too. And all 4 dies were perfectly the same brightness, even at very low intensities. I ruined the perfect P7, just to rig a quick demo off my PSU to impress people at work. Damn

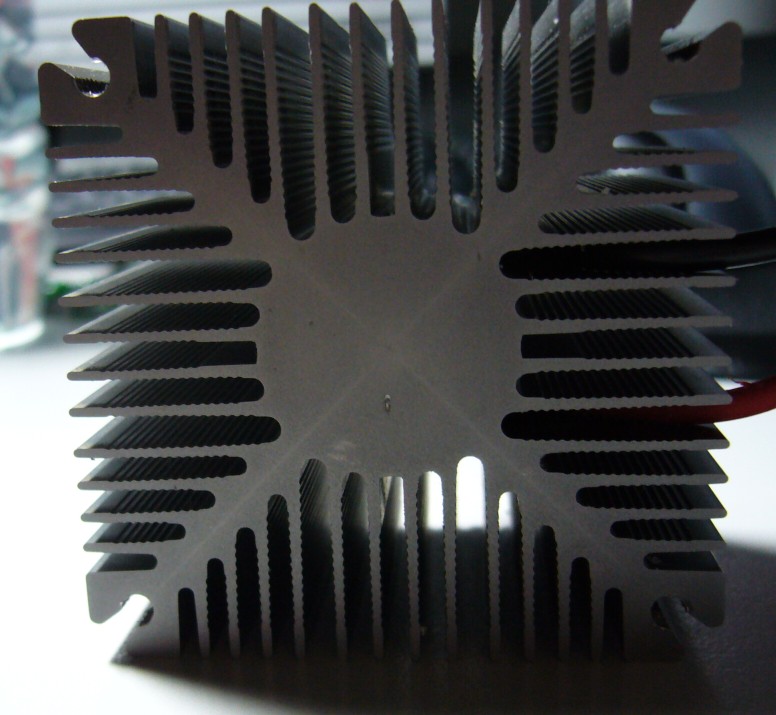

I just underestimated those trustfire 18650 cells. One in direct drive (on a good heatsink) was pretty bright.

Then i thought: Maybe two in parallel might be brighter (less internal resistance).

Well, it turned out that mine had a very low Vf, too (i idiot even meassured it before, i hit 4A at 3.905V at the psu, minus probing head contact resistance this is more like 3.8V.

And those were fresh 18650.

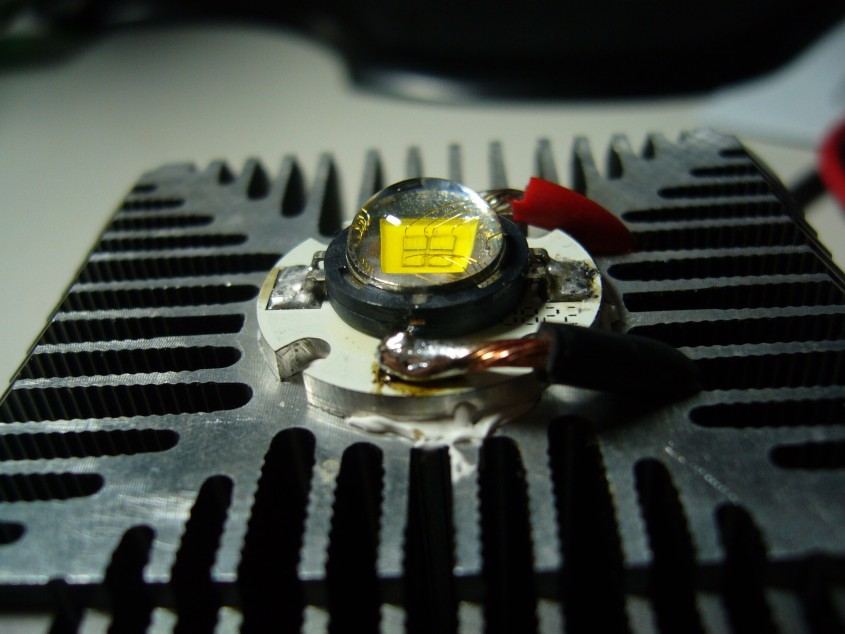

To make a long talk short, it seems my P7 had a very near dead experience, with a very curious failure mode:

A dark spot on one of the dies, plus a 20 Ohm parasitic resistence path ( i get 100mA at 2V, where i got non before).

It seems the bonding wires are all fine, so the question is: How did it fail? Electromigration creating a conductive path through the die?

Pics and a video to follow...

I just underestimated those trustfire 18650 cells. One in direct drive (on a good heatsink) was pretty bright.

Then i thought: Maybe two in parallel might be brighter (less internal resistance).

Well, it turned out that mine had a very low Vf, too (i idiot even meassured it before, i hit 4A at 3.905V at the psu, minus probing head contact resistance this is more like 3.8V.

And those were fresh 18650.

To make a long talk short, it seems my P7 had a very near dead experience, with a very curious failure mode:

A dark spot on one of the dies, plus a 20 Ohm parasitic resistence path ( i get 100mA at 2V, where i got non before).

It seems the bonding wires are all fine, so the question is: How did it fail? Electromigration creating a conductive path through the die?

Pics and a video to follow...

Last edited: