Endeavour

Flashlight Enthusiast

Hello Everyone,

As the final chapter of the Mako AAA project comes to a close I wanted to take a moment and rewrite this post to detail in one place the project in full, and express once more what the objectives behind this design are so that you all know what to expect when you receive your light in the coming weeks.

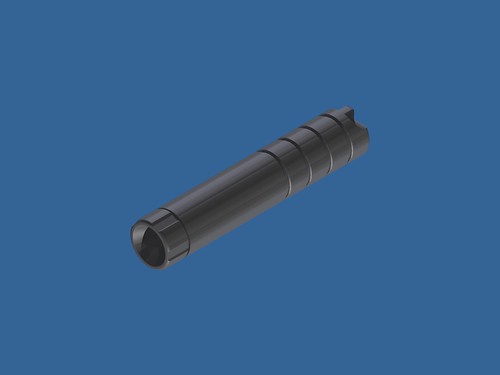

The Mako AAA is my take on the backup light. The driving objectives were to create a small, unobtrusive torch that ran for a very long time off of a common cell, in a durable package, with some compelling features at an affordable price point. With two stages, 20 hours runtime on high mode and 60 hours on low, and 6AL4V Titanium construction, I feel that those objectives have been well satisfied.

For the project I sourced a new LED which had not yet found its use into flashlights; a 5mm LED from Cree, which had the best color of any of the 5mm LEDs I'd used to date. I designed a true current regulator to provide 6mA and 20mA to the LED on low and high mode, respectively, which provides a reasonable amount of output from the LED and keeps everything within the limits of the part so that you don't end up with a huge blue tint shift and the toasting your LED prematurely as will happen with all the lights pushing 3-4 times the rated maximum current into the parts.

I've now completed all the lights and tested them; their tints vary slightly from unit to unit as is common across all LED types, and these are a slightly cool to neutral white with decent color uniformity. The beam will not be perfect, as is the nature of 5mm LEDs, but at a distance of 10 feet or so, it's nice. The beam has a dim, incidental corona (somewhat similar in character to my old CR2 Ion XT) due to the LED not being 100% efficient in emitting its light within the 15 degrees it's rated at, and the presence of the main spot within the beam is variable from unit to unit. This could have been countered by sacrificing water resistance and blocking off all the sides of the LED except for the very tip, but the general practicality afforded by water resistance was not a sacrifice I was willing to make. Overall I am quite happy with the end result of the Mako and it suits the design parameters I had in mind, but I did want everyone to be aware in advance what the nature of the beast was, and understand that while these LEDs are the best I've tried in their class, they are still 5mm LEDs and still have some of the strengths and weaknesses thereof.

With regards to the brightness levels proper, the Mako can be viewed as having two distinct levels, but you should think of them more as full power, and power save mode. High mode is providing a fair amount of light more than low mode, but it's not as dramatic a difference as what some of you may be used to in my previous lights like the Aeon and Nautilus. Both of those lights have a 10:1 power ratio, whereas the Mako is roughly 4:1, and it's simply not possible to have that high of a ratio on a light with a maximum current of 20mA.

Moving from the driver to what batteries you should feed your Mako – Any standard AAA cell, as well as any properly manufactured rechargeable cell that charges to around 1.5V will work fine. For rechargeables, I'd highly recommend cells like the Sanyo Eneloop (which is what I will be using in my light), or lithium primaries, though. The Eneloops are a very low self discharge NiMH battery and are well suited to low current, long shelf life applications like the Mako. Lithium Primaries have less likelihood of leaking than alkaline batteries, and provide a slight boost in runtime. Each Mako comes equipped with a Duracell Alkaline AAA as standard, and if you choose to run such cells in it exclusively be sure to check on the light periodically to make sure that the cell is still intact and replace it if it goes past the expiration date on the label.

A summary of the light's features:

- AAA Based

- 13mm Diameter x 68mm Long

- 24,000mcd Cree 5mm LED

- Machined from 6AL4V Titanium, Bead Blasted

- 24K Gold Plated Contacts

- Dual Stage, Fully Regulated DC/DC Converter

- Water Resistant

- Equipped with a split ring and capable of tailstanding

Through the past several months the design has undergone some changes, finally arriving to the point where we're at today:

The finish of the parts and quality of machining has turned out quite nice, and I'm very happy with the final results. My thanks goes out to all of you who had the patience to stick with the project; The Mako took a little longer to come into being than originally anticipated, but I'm looking forward hearing your thoughts when you receive your lights soon.

The vast majority of all Makos have shipped out today, inclusive of international orders, and I suspect most of you will have them in hand by sometime next week.

In the meantime, if anyone has any questions or comments, please post here or send me an e-mail at [email protected]

Thanks folks!

-Enrique

As the final chapter of the Mako AAA project comes to a close I wanted to take a moment and rewrite this post to detail in one place the project in full, and express once more what the objectives behind this design are so that you all know what to expect when you receive your light in the coming weeks.

The Mako AAA is my take on the backup light. The driving objectives were to create a small, unobtrusive torch that ran for a very long time off of a common cell, in a durable package, with some compelling features at an affordable price point. With two stages, 20 hours runtime on high mode and 60 hours on low, and 6AL4V Titanium construction, I feel that those objectives have been well satisfied.

For the project I sourced a new LED which had not yet found its use into flashlights; a 5mm LED from Cree, which had the best color of any of the 5mm LEDs I'd used to date. I designed a true current regulator to provide 6mA and 20mA to the LED on low and high mode, respectively, which provides a reasonable amount of output from the LED and keeps everything within the limits of the part so that you don't end up with a huge blue tint shift and the toasting your LED prematurely as will happen with all the lights pushing 3-4 times the rated maximum current into the parts.

I've now completed all the lights and tested them; their tints vary slightly from unit to unit as is common across all LED types, and these are a slightly cool to neutral white with decent color uniformity. The beam will not be perfect, as is the nature of 5mm LEDs, but at a distance of 10 feet or so, it's nice. The beam has a dim, incidental corona (somewhat similar in character to my old CR2 Ion XT) due to the LED not being 100% efficient in emitting its light within the 15 degrees it's rated at, and the presence of the main spot within the beam is variable from unit to unit. This could have been countered by sacrificing water resistance and blocking off all the sides of the LED except for the very tip, but the general practicality afforded by water resistance was not a sacrifice I was willing to make. Overall I am quite happy with the end result of the Mako and it suits the design parameters I had in mind, but I did want everyone to be aware in advance what the nature of the beast was, and understand that while these LEDs are the best I've tried in their class, they are still 5mm LEDs and still have some of the strengths and weaknesses thereof.

With regards to the brightness levels proper, the Mako can be viewed as having two distinct levels, but you should think of them more as full power, and power save mode. High mode is providing a fair amount of light more than low mode, but it's not as dramatic a difference as what some of you may be used to in my previous lights like the Aeon and Nautilus. Both of those lights have a 10:1 power ratio, whereas the Mako is roughly 4:1, and it's simply not possible to have that high of a ratio on a light with a maximum current of 20mA.

Moving from the driver to what batteries you should feed your Mako – Any standard AAA cell, as well as any properly manufactured rechargeable cell that charges to around 1.5V will work fine. For rechargeables, I'd highly recommend cells like the Sanyo Eneloop (which is what I will be using in my light), or lithium primaries, though. The Eneloops are a very low self discharge NiMH battery and are well suited to low current, long shelf life applications like the Mako. Lithium Primaries have less likelihood of leaking than alkaline batteries, and provide a slight boost in runtime. Each Mako comes equipped with a Duracell Alkaline AAA as standard, and if you choose to run such cells in it exclusively be sure to check on the light periodically to make sure that the cell is still intact and replace it if it goes past the expiration date on the label.

A summary of the light's features:

- AAA Based

- 13mm Diameter x 68mm Long

- 24,000mcd Cree 5mm LED

- Machined from 6AL4V Titanium, Bead Blasted

- 24K Gold Plated Contacts

- Dual Stage, Fully Regulated DC/DC Converter

- Water Resistant

- Equipped with a split ring and capable of tailstanding

Through the past several months the design has undergone some changes, finally arriving to the point where we're at today:

The finish of the parts and quality of machining has turned out quite nice, and I'm very happy with the final results. My thanks goes out to all of you who had the patience to stick with the project; The Mako took a little longer to come into being than originally anticipated, but I'm looking forward hearing your thoughts when you receive your lights soon.

The vast majority of all Makos have shipped out today, inclusive of international orders, and I suspect most of you will have them in hand by sometime next week.

In the meantime, if anyone has any questions or comments, please post here or send me an e-mail at [email protected]

Thanks folks!

-Enrique

Last edited:

Enrique!! Looking forward to your latest creation. :thumbsup:

Enrique!! Looking forward to your latest creation. :thumbsup: