MrNaz

Enlightened

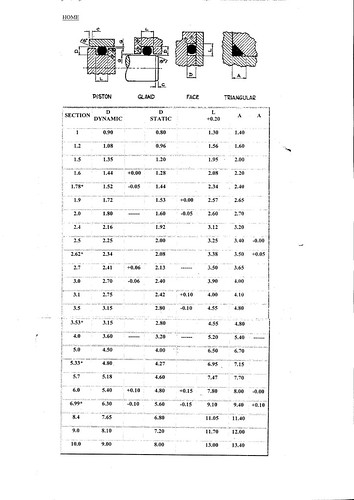

Previously I was stabbing in the dark when deciding on groove sizes for orings, and then I found a technical document from an engineering company. It was all in imperial units, so I converted it to metric, selecting the orings that flashlight modders and builders are likely to use. Here are the values, I hope someone finds this useful!

CS GD GW

1.60 1.17 2.21

1.78 1.25 2.54

2.00 1.44 2.81

2.50 1.89 3.37

2.62 1.98 3.48

3.00 2.23 3.99

3.53 2.74 4.52

4.00 3.18 5.12

CS = Cross sectional diameter of oring

GD = Suggested Groove Depth

GW = Suggested Groove Width

These values result in optimal compression of orings, and the information was found on this page:

http://www.row-inc.com/sizes.html

Is there a place I can add all the useful technical data I am collecting? It seems that this is the sort of information that people must look up again and again, and it'd be useful if there was some central repository for this knowledge. Or is the collective CPF mind supposed to do that? :twothumbs

CS GD GW

1.60 1.17 2.21

1.78 1.25 2.54

2.00 1.44 2.81

2.50 1.89 3.37

2.62 1.98 3.48

3.00 2.23 3.99

3.53 2.74 4.52

4.00 3.18 5.12

CS = Cross sectional diameter of oring

GD = Suggested Groove Depth

GW = Suggested Groove Width

These values result in optimal compression of orings, and the information was found on this page:

http://www.row-inc.com/sizes.html

Is there a place I can add all the useful technical data I am collecting? It seems that this is the sort of information that people must look up again and again, and it'd be useful if there was some central repository for this knowledge. Or is the collective CPF mind supposed to do that? :twothumbs

Last edited: