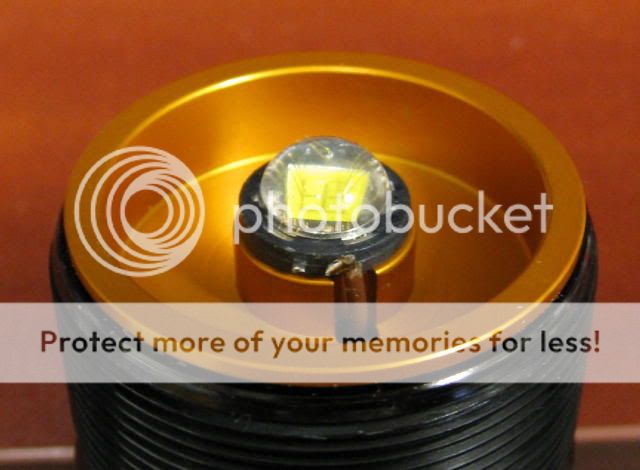

big beam

Enlightened

Been thinking about building 2 of these for a while now but would like input from those that have built them before.

Can you use al reflectors like lightedge or litho sells?Or do you just cut down a stock mag reflector?Is there a difference between the heat sinks that are sold here on CPF or are they all about the same "spec"?Should I be looking for a certain vf in the MC-E I'd be using?I have installed a Kui socket in a hotwire so I know how to cut down a mag switch and solder the wires to the switch.Any and all help would be welcome!

DON

One more question,does the heatsink press fit in the light or do you have to use thermal epoxy or something else to secure it?

Can you use al reflectors like lightedge or litho sells?Or do you just cut down a stock mag reflector?Is there a difference between the heat sinks that are sold here on CPF or are they all about the same "spec"?Should I be looking for a certain vf in the MC-E I'd be using?I have installed a Kui socket in a hotwire so I know how to cut down a mag switch and solder the wires to the switch.Any and all help would be welcome!

DON

One more question,does the heatsink press fit in the light or do you have to use thermal epoxy or something else to secure it?

Last edited:

I didn't even see DD in the title. Sorry about that.

I didn't even see DD in the title. Sorry about that.