lewong

Newly Enlightened

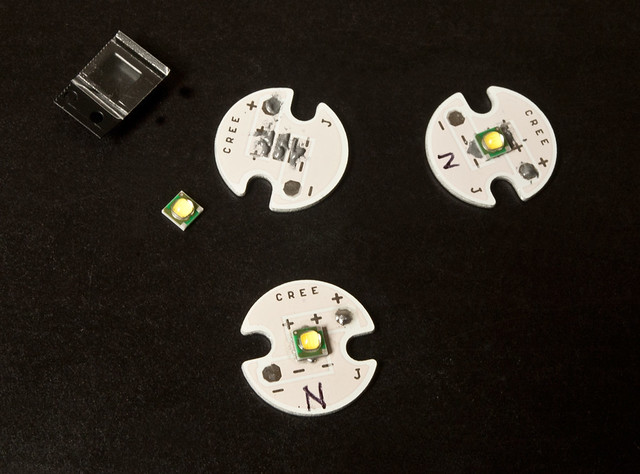

On this Youtube video, Steve Dahl at DigiKey demonstrates a method of soldering high-brightness LEDs to a thermal pad using a heat gun.

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

Doesn't the die fry when exposed to 600 F? How does he control how hot the die gets?

Very educational.

Where can I get this soldering paste?

:thinking:

:thanks:

Very educational.

Where can I get this soldering paste?

:thinking:

:thanks:

It's ok if it's for a short period of time. That's why there's a soldering profile in the spec sheets. That's why it's important to have good hot air gun one where you can control the heat.

You want to set the gun to just melt the paste but not super hot so it exceeds the max temp in the profile in the sheets. I think the XR-E can take 500F for like 1 minute(I'm going from memory).