wquiles

Flashaholic

This custom 6D is part of an order from one of my customers in the UK. He asked for 3 custom black "D" Mags, all done with the same head/body grooving:

- 1xD with a P7 in DD from 3xAA

- 2xD with a 6xAA adapter

- 6xD custom with a P7 and regulated driver

Here you can see the 3 black bodies, along with other Mag's. From left to right: OEM Dark Silver (Pewter) 2xC, WQ 1xD Copper, WQ 1xD Black, OEM 2xD Black, OEM 3xD Digital Camo, OEM 3xD Purple, OEM 4xD Copper, OEM 6xD Black:

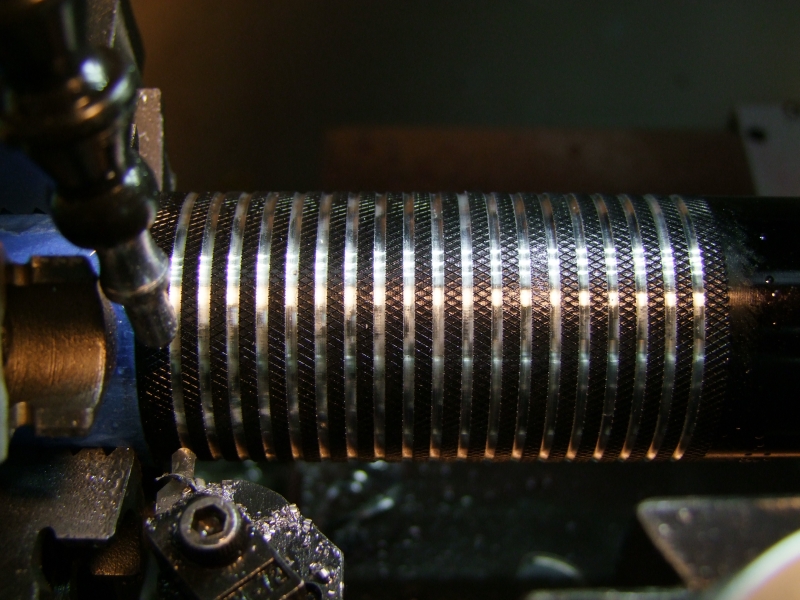

Here I am doing body grooving on the 2xD host:

Here is how it looks when I am done:

Here is a short movie of the body grooving process:

Mag D Body Grooving

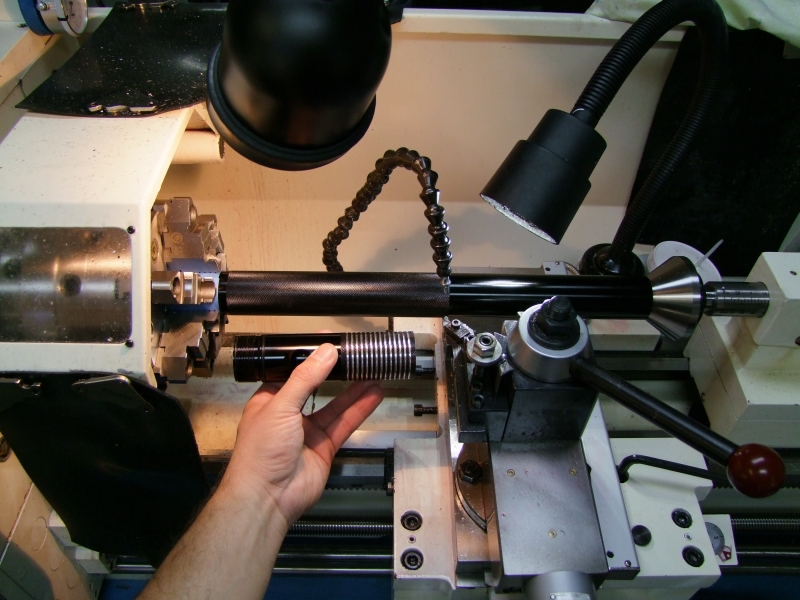

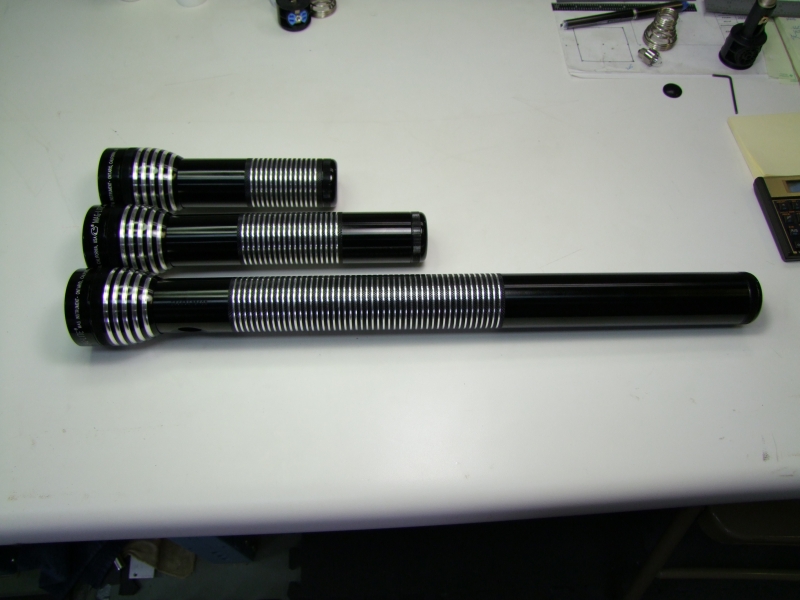

Here the just completed 2xD next to the already completed 1xD, and the soon to be completed 6xD host:

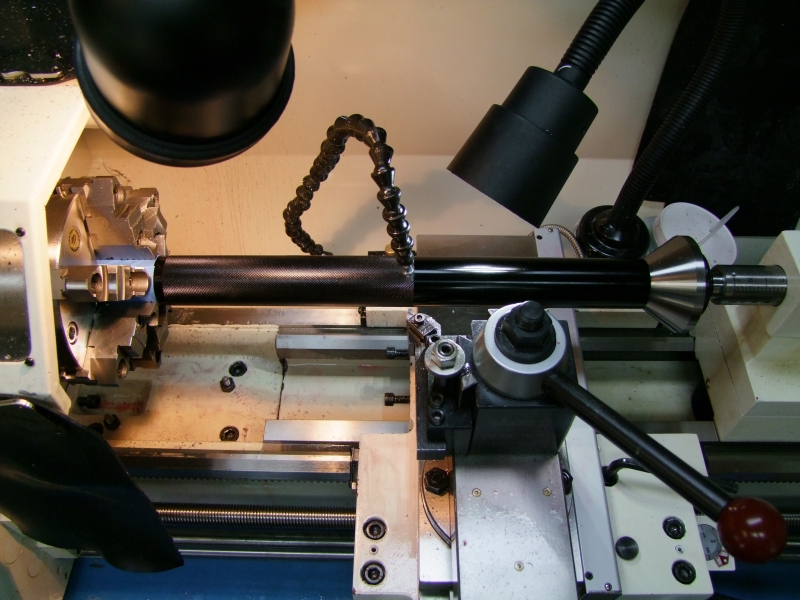

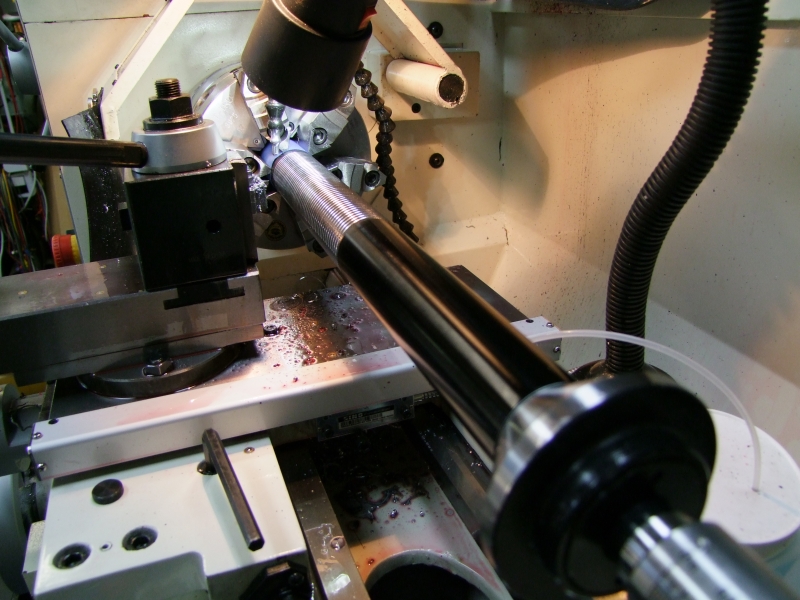

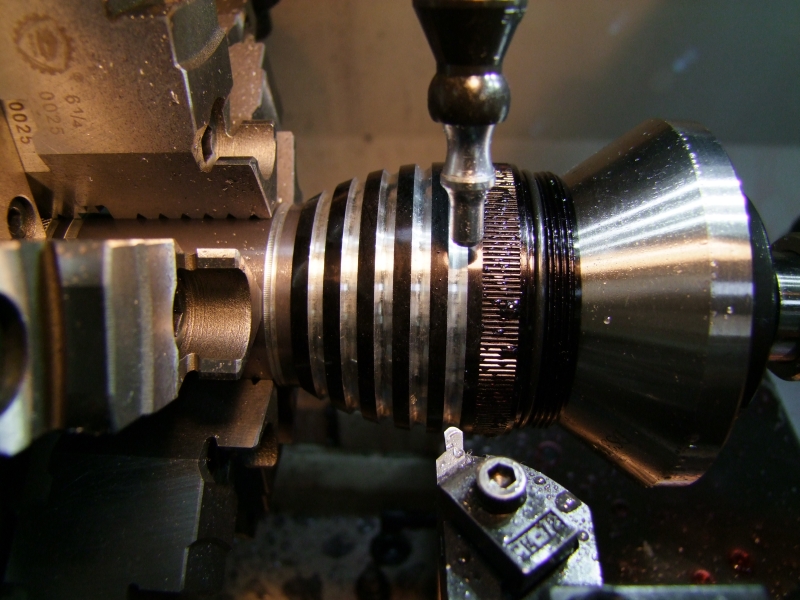

Here is the 6xD on the lathe - I knew there was a good reason I got the 12x36 lathe!:

All 3 of them done now:

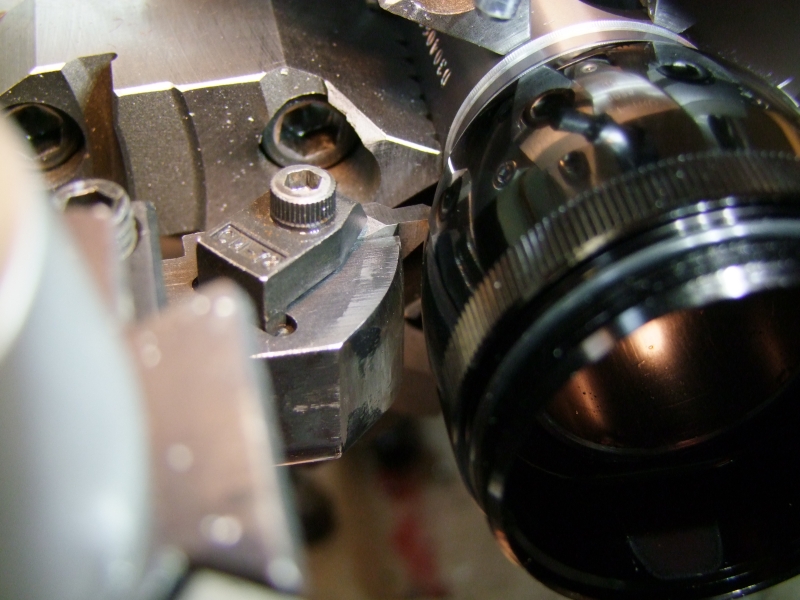

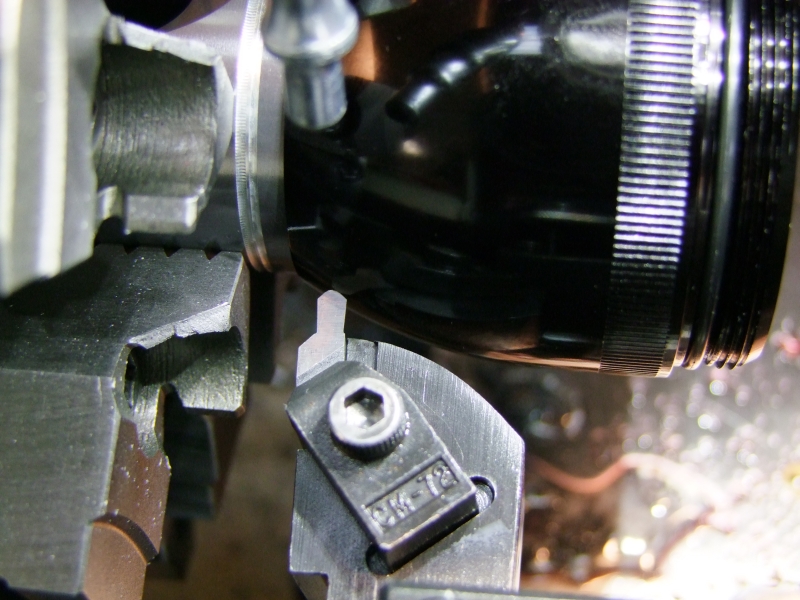

For the head grooving, I wanted to try a more rounded bit, so I had to first grind the end of the holder to get extra clearance:

Here is the completed head:

Here is another short video, this one about the head grooving:

http://www.youtube.com/watch?v=fI8kzJWEpW4

Completed 2xD host with mdocod 6xAA holder:

And all 3 hosts completed:

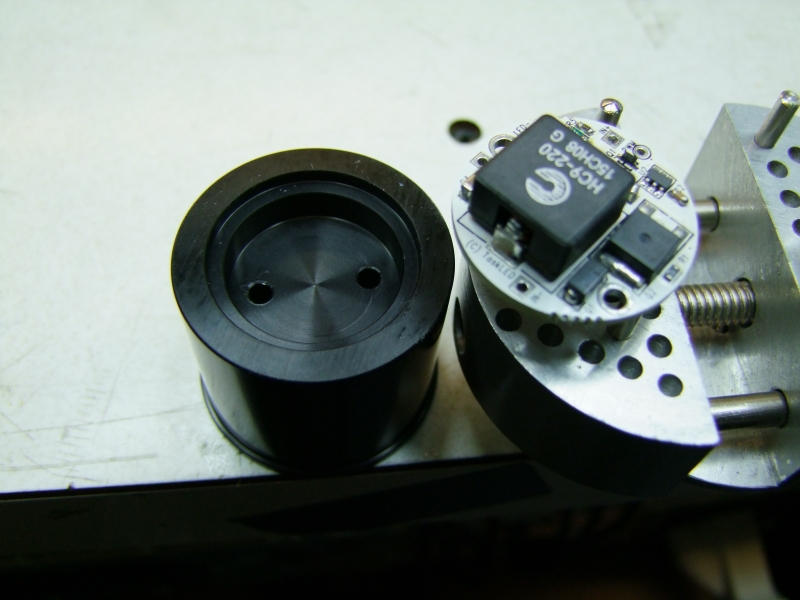

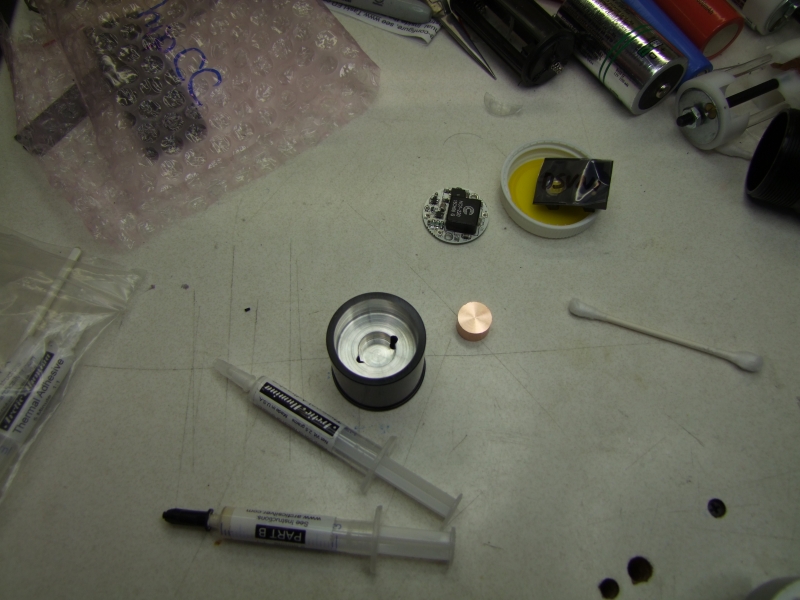

OK, so here are the parts for the custom 6D:

Unfortunately the hipCC does not quite fit on the Britelumens P7 heatsink:

Plus, even if it fit diameter-wise, you still have to figure out how to provide a thermal path and wire the LED, so I needed a way to "suspend" the driver inside the heatsink. Since I had pure copper left from my diving head project, I decided to use it.

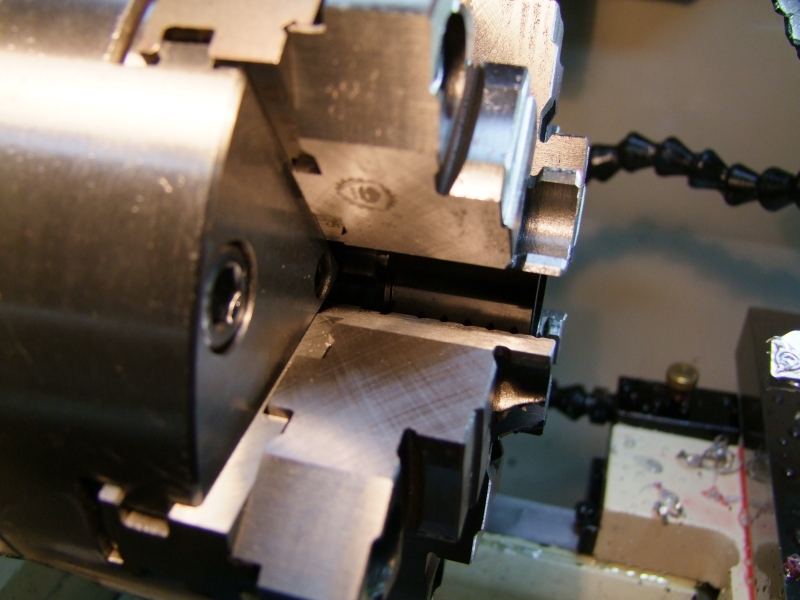

First I had to modify the heatsink and make the hole for the copper plug - luckily the jaws on my chuck have a small cutout that matches perfectly the lip on the heatsink:

After a couple of operations, I got the heatsink ready:

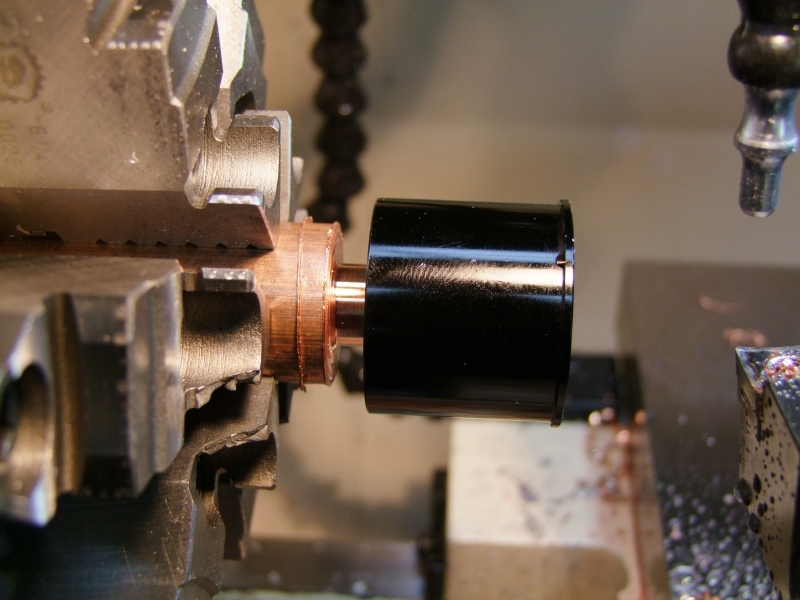

I then made the fitted copper plug:

Check for fit:

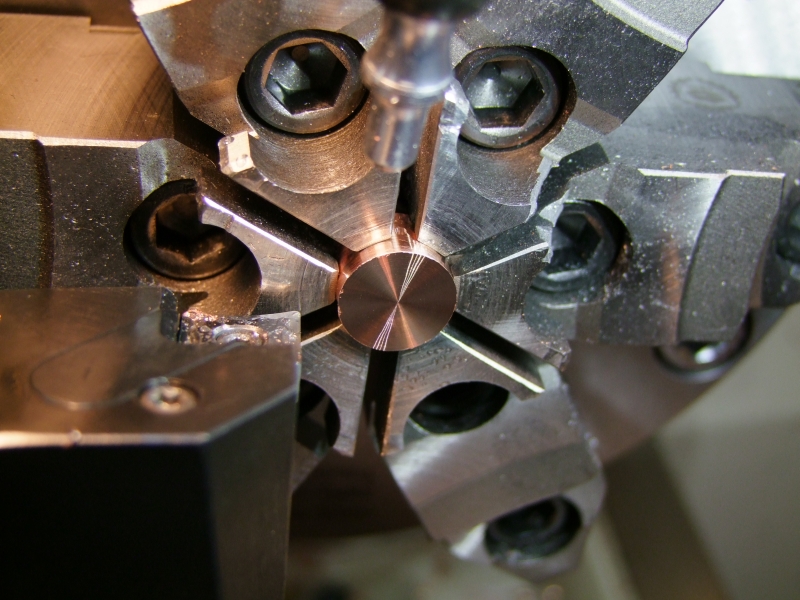

Clean the cut-off side for good thermal transfer:

Ready:

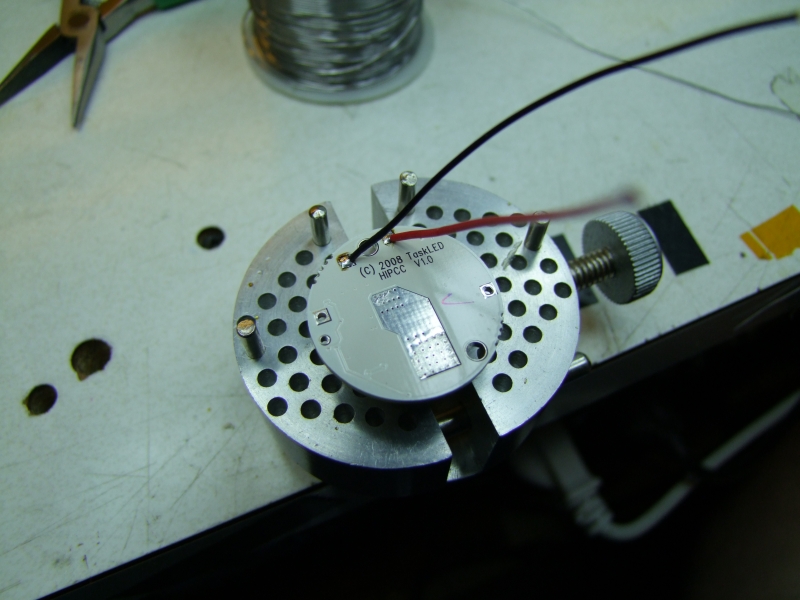

This is how the hipCC fits:

Use thermal epoxy to set the plug in place permanently:

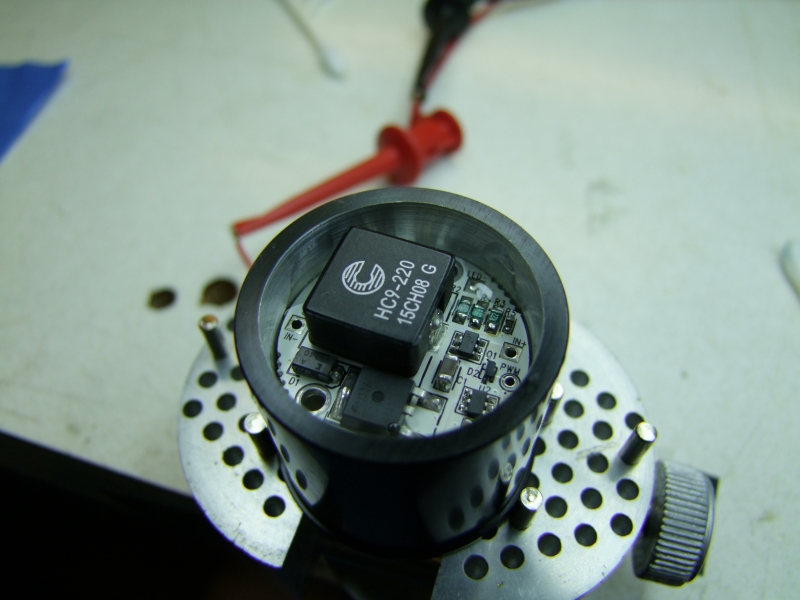

Wire the hipCC:

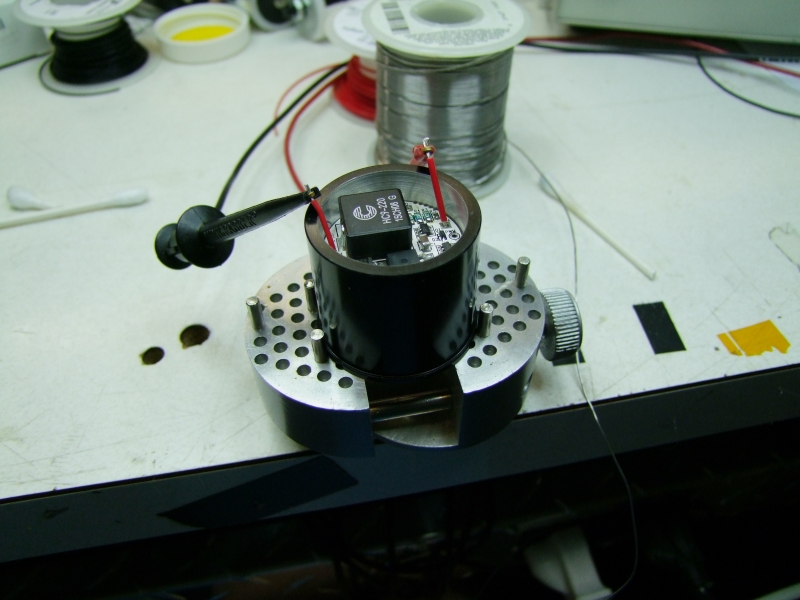

Use 3M 10mil thermal two-sided tape and solder P7 wires:

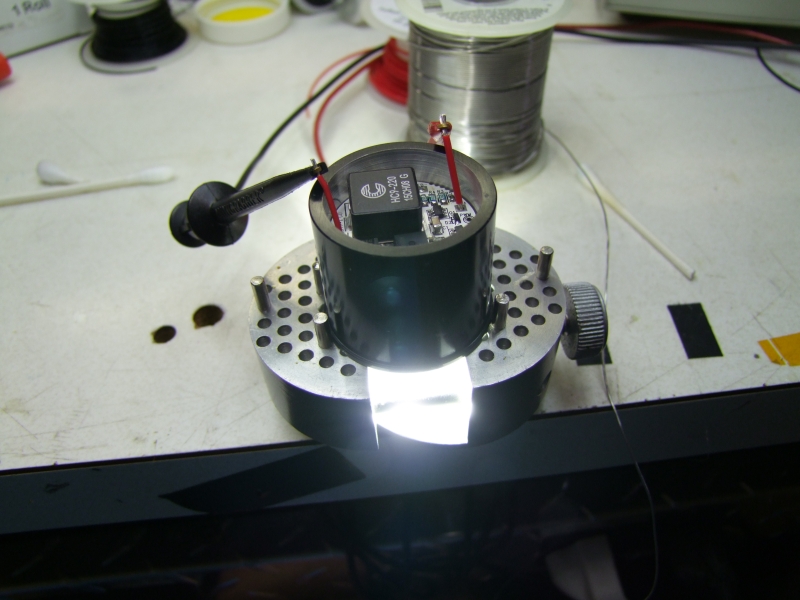

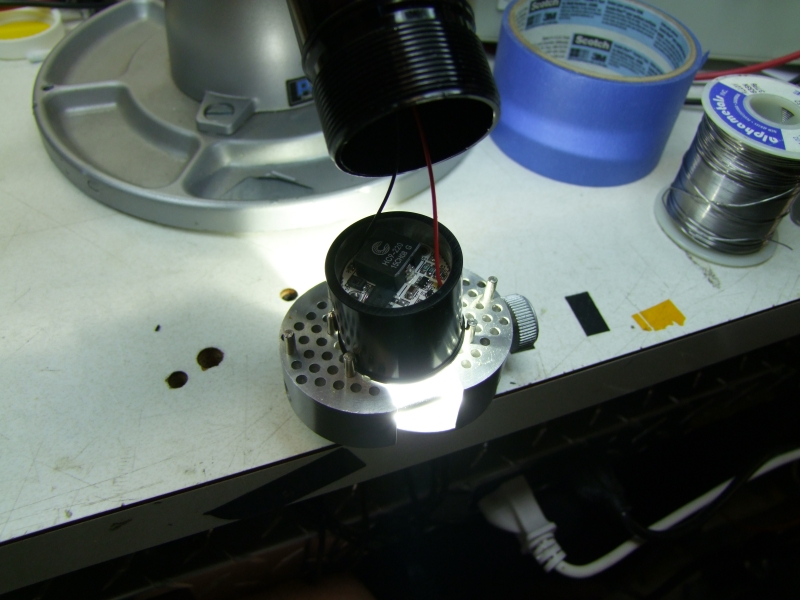

Test it on my bench supply:

Set the driver in place with two-part clear epoxy applied over the edge of the driver at 3 places:

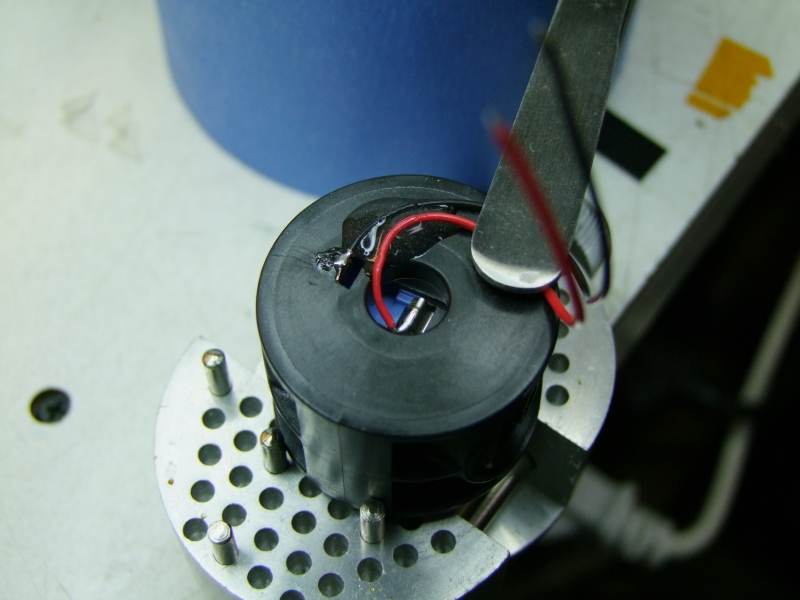

Solder, pre-bend, and epoxy wires in place:

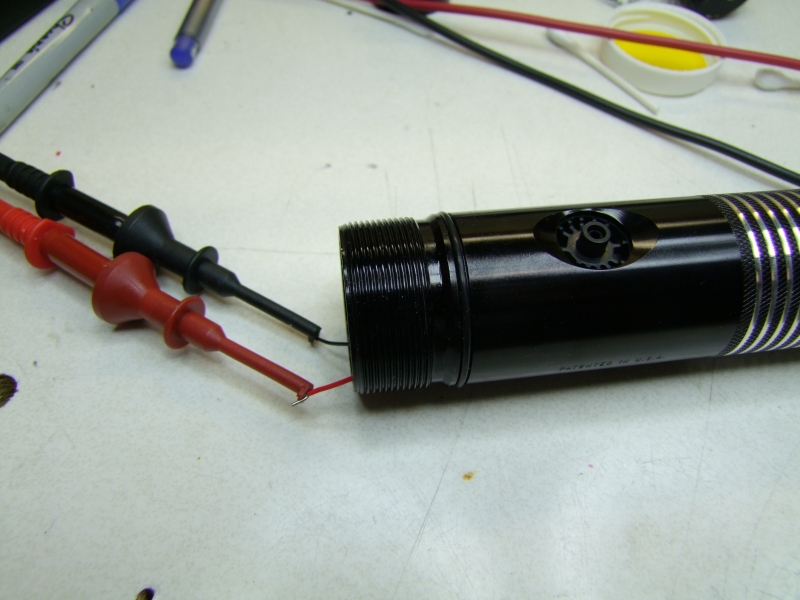

Test switch/wiring just in case (using 6x "D" Alkaline cells):

Solder driver and test one more time (again using the Alkaline cells):

I have not cleaned yet the excess thermal epoxy in these pics, but it is now almost ready:

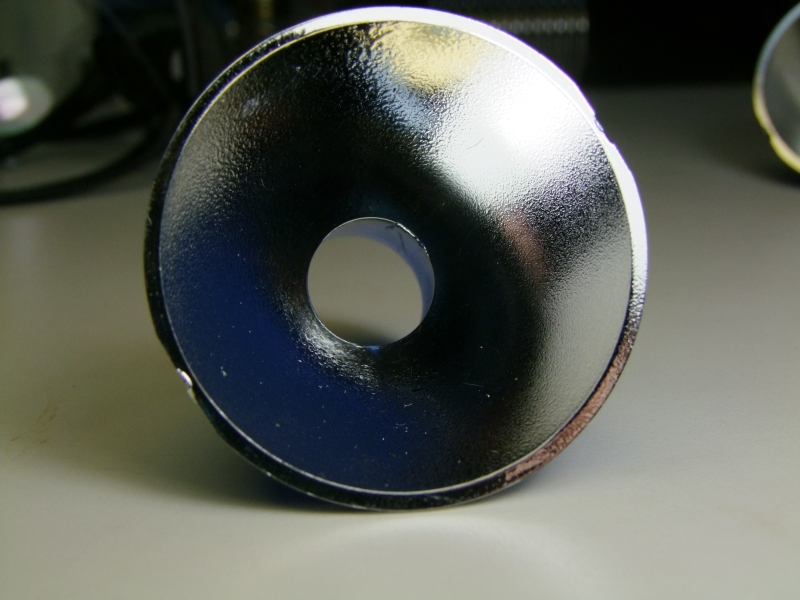

Final step was to sputter some of the OEM plastic reflectors (inspired by forum member darkzero, who does a fantastic job on this process). I have been practicing some, and they are getting better and better (some dust on the reflectors while taking the picture!):

Here is the final shot of the reflectors once installed on the 1xD and the 6xD:

Will

- 1xD with a P7 in DD from 3xAA

- 2xD with a 6xAA adapter

- 6xD custom with a P7 and regulated driver

Here you can see the 3 black bodies, along with other Mag's. From left to right: OEM Dark Silver (Pewter) 2xC, WQ 1xD Copper, WQ 1xD Black, OEM 2xD Black, OEM 3xD Digital Camo, OEM 3xD Purple, OEM 4xD Copper, OEM 6xD Black:

Here I am doing body grooving on the 2xD host:

Here is how it looks when I am done:

Here is a short movie of the body grooving process:

Mag D Body Grooving

Here the just completed 2xD next to the already completed 1xD, and the soon to be completed 6xD host:

Here is the 6xD on the lathe - I knew there was a good reason I got the 12x36 lathe!:

All 3 of them done now:

For the head grooving, I wanted to try a more rounded bit, so I had to first grind the end of the holder to get extra clearance:

Here is the completed head:

Here is another short video, this one about the head grooving:

http://www.youtube.com/watch?v=fI8kzJWEpW4

Completed 2xD host with mdocod 6xAA holder:

And all 3 hosts completed:

OK, so here are the parts for the custom 6D:

Unfortunately the hipCC does not quite fit on the Britelumens P7 heatsink:

Plus, even if it fit diameter-wise, you still have to figure out how to provide a thermal path and wire the LED, so I needed a way to "suspend" the driver inside the heatsink. Since I had pure copper left from my diving head project, I decided to use it.

First I had to modify the heatsink and make the hole for the copper plug - luckily the jaws on my chuck have a small cutout that matches perfectly the lip on the heatsink:

After a couple of operations, I got the heatsink ready:

I then made the fitted copper plug:

Check for fit:

Clean the cut-off side for good thermal transfer:

Ready:

This is how the hipCC fits:

Use thermal epoxy to set the plug in place permanently:

Wire the hipCC:

Use 3M 10mil thermal two-sided tape and solder P7 wires:

Test it on my bench supply:

Set the driver in place with two-part clear epoxy applied over the edge of the driver at 3 places:

Solder, pre-bend, and epoxy wires in place:

Test switch/wiring just in case (using 6x "D" Alkaline cells):

Solder driver and test one more time (again using the Alkaline cells):

I have not cleaned yet the excess thermal epoxy in these pics, but it is now almost ready:

Final step was to sputter some of the OEM plastic reflectors (inspired by forum member darkzero, who does a fantastic job on this process). I have been practicing some, and they are getting better and better (some dust on the reflectors while taking the picture!):

Here is the final shot of the reflectors once installed on the 1xD and the 6xD:

Will

i really cant wait till i get them delivered!! thanks for your help,videos and photo during and after:thumbsup:

i really cant wait till i get them delivered!! thanks for your help,videos and photo during and after:thumbsup: