Hi, Per-Sev.

Thanks for the warning. You're absolutely right. I can't see how the pipes are fed up into the wall, looking up from the floor below, so there is the possibility of damaging piping inside.

Out of stupidity, when I first found out the valve didn't turn, I sprayed on a bit of WD40

. Just a bit, but I'm now suspicious whether THAT is what I'm tasting

.

Hi, Photowiz.

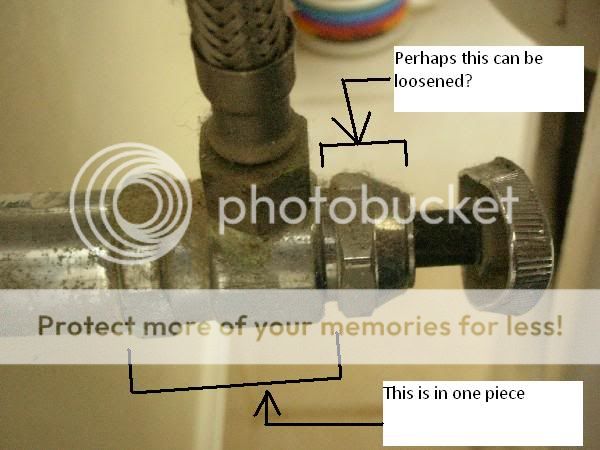

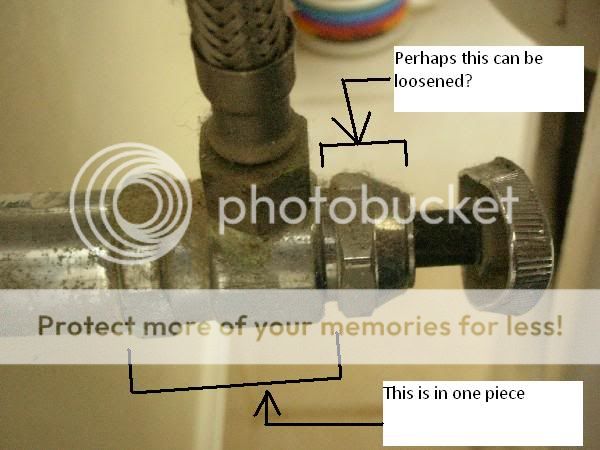

I had worked on the cold water valve, just opposite the one in the pics, before posting here. I was stripping the chrome plating and beginning to strip the flats right in front of the sleeve and it didn't budge at all. That's when I realized, "Crap! The thing could be soldered on." Since I can't see piping in the wall, I'm not confident that it is well secured and supported as you suggested, judging by the workmanship that went into the rest of the house :thumbsdow.

MarNav1,

It sounds like I need to open up a hole in the wall, too?

. My coworker advised me not to use a pipe wrench on flats, because it is a pipe wrench and pipes are round. I did try putting a pipe wrench on the flats but it kept slipping when I cranked on it. Any tips?

Let's say the valve has been threaded-on and I've removed the sleeve. How do I grab the copper pipe without damaging it or deforming it when I try again to unscrew the valve. Just wrap it with a thick towel and put a pipe wrench on it?

McFlyFyter

I tried twisting on the flats in the front as well and, like the flats in the back, it didn't budge. I hope to replace it, you know, get a clean start.

So the consensus sounds like, before further twisting and cranking, the first order of business: the sleeve is coming off.

I'll keep you guys updated, but don't hold your breath :green:. Work at the office is picking up and I got some personal stuff to attend to. The boundary between the work week and weekends are...beginning to blur.:shakehead

Thank you all.

. Just a bit, but I'm now suspicious whether THAT is what I'm tasting

. Just a bit, but I'm now suspicious whether THAT is what I'm tasting  . My coworker advised me not to use a pipe wrench on flats, because it is a pipe wrench and pipes are round. I did try putting a pipe wrench on the flats but it kept slipping when I cranked on it. Any tips?

. My coworker advised me not to use a pipe wrench on flats, because it is a pipe wrench and pipes are round. I did try putting a pipe wrench on the flats but it kept slipping when I cranked on it. Any tips?