PCC

Flashlight Enthusiast

Yeah, I think I voided the warranty on this one. I think my son will be upset with me, too, since this was his light (I'll buy him a new one).

First of all, I've always wondered how they put this light together and my curiosity got the better of me today. It doesn't help that I needed to get my mind off of recent events in my life. This thread was the spark that I needed to get me moving on this.

The emitter module is pressed in from the battery side. Some light taps with a rubber mallet onto a flat blade screwdriver with the blade placed beside the emitter (much like you would try to take a Rebel Mini-MagLite apart) will eventually get the module out.

The retaining ring itself is screwed into the body of the light from the battery compartment side. The tools required to take these apart are a strap wrench and a long 12mm Allen wrench. The slots that you are engaging are tapered, starting at about 12.5mm at the battery side and about 11.5mm at the lens side.

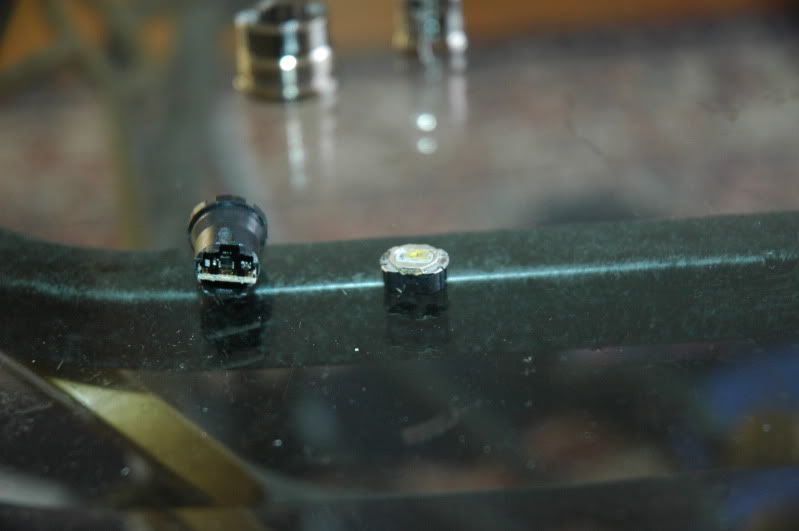

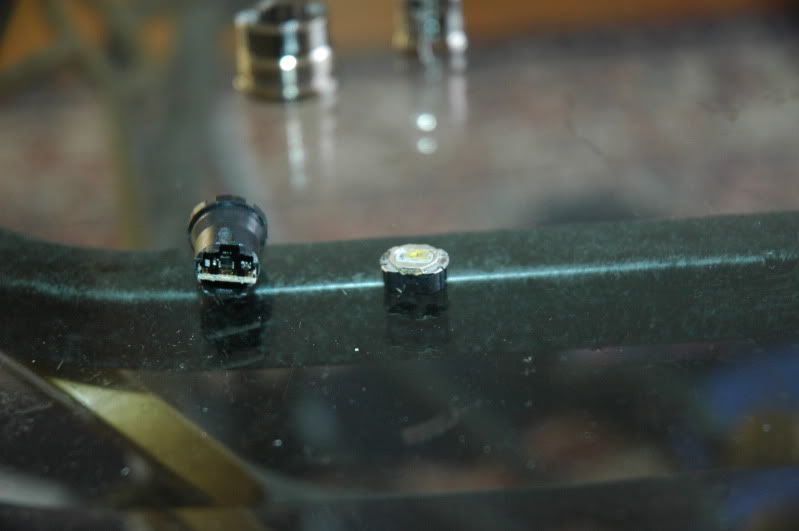

The module itself looks almost like the same modules that Mag uses in their Rebel LED lights but I'm pretty sure that the board on this one is different. Apparently, the tailcap of the XL100 controls the negative current to the emitter to control the modes so I thought that the emitter module might simply be an LED without any circuitry but there is a resistor and a small chip on the board. I haven't taken the board out of its plastic holder, yet, because they glued it into place.

The module itself was something that I wanted to take apart, too, so I took this one apart since I had cut the cannister while trying to remove the retaining ring and I accidentally knocked the dome of the Rebel emitter off during deconstruction. It looks to me like there is a small circuit board sandwiched between a thin metal ring on top and the plastic piece with the contacts on the bottom. I'm going to guess that the glued it together. This sandwich is then glied to the can, exposing only the very top of the sandwich.

As a likely mod candidate I would not use this light. The gee-whiz UI is pretty cool but the fact is that it will take a lot of effort to do anything with this light as a host. I do not know if the tailcap will work with a Sandwich Shop driver nor do I think that direct-driving an LED using only the tailcap current to drive it would work well. I have to try it, though.

First of all, I've always wondered how they put this light together and my curiosity got the better of me today. It doesn't help that I needed to get my mind off of recent events in my life. This thread was the spark that I needed to get me moving on this.

The emitter module is pressed in from the battery side. Some light taps with a rubber mallet onto a flat blade screwdriver with the blade placed beside the emitter (much like you would try to take a Rebel Mini-MagLite apart) will eventually get the module out.

The retaining ring itself is screwed into the body of the light from the battery compartment side. The tools required to take these apart are a strap wrench and a long 12mm Allen wrench. The slots that you are engaging are tapered, starting at about 12.5mm at the battery side and about 11.5mm at the lens side.

The module itself looks almost like the same modules that Mag uses in their Rebel LED lights but I'm pretty sure that the board on this one is different. Apparently, the tailcap of the XL100 controls the negative current to the emitter to control the modes so I thought that the emitter module might simply be an LED without any circuitry but there is a resistor and a small chip on the board. I haven't taken the board out of its plastic holder, yet, because they glued it into place.

The module itself was something that I wanted to take apart, too, so I took this one apart since I had cut the cannister while trying to remove the retaining ring and I accidentally knocked the dome of the Rebel emitter off during deconstruction. It looks to me like there is a small circuit board sandwiched between a thin metal ring on top and the plastic piece with the contacts on the bottom. I'm going to guess that the glued it together. This sandwich is then glied to the can, exposing only the very top of the sandwich.

As a likely mod candidate I would not use this light. The gee-whiz UI is pretty cool but the fact is that it will take a lot of effort to do anything with this light as a host. I do not know if the tailcap will work with a Sandwich Shop driver nor do I think that direct-driving an LED using only the tailcap current to drive it would work well. I have to try it, though.